Fully-automatic control device for coating ingredients of K gold electrocasting and system

A coating and electroforming technology, applied in measuring devices, multiple fluid ratio control, analyzing materials, etc., can solve problems such as low quality and low efficiency, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

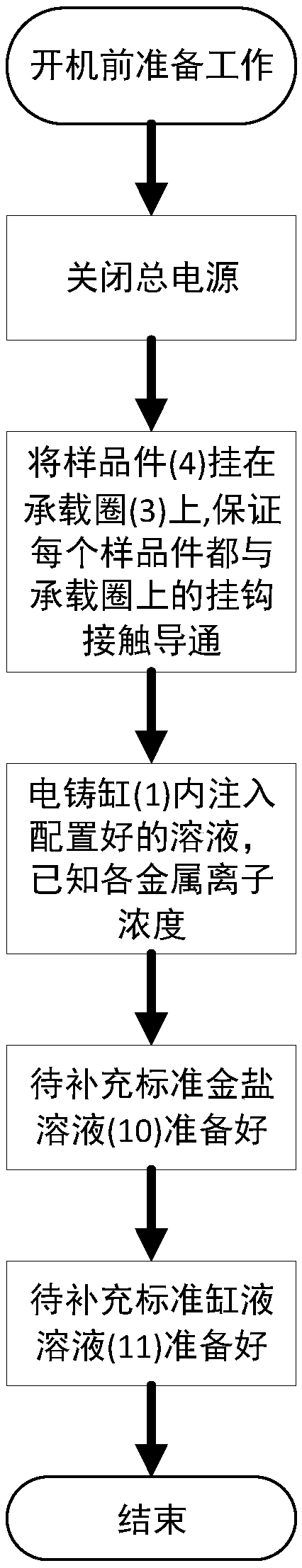

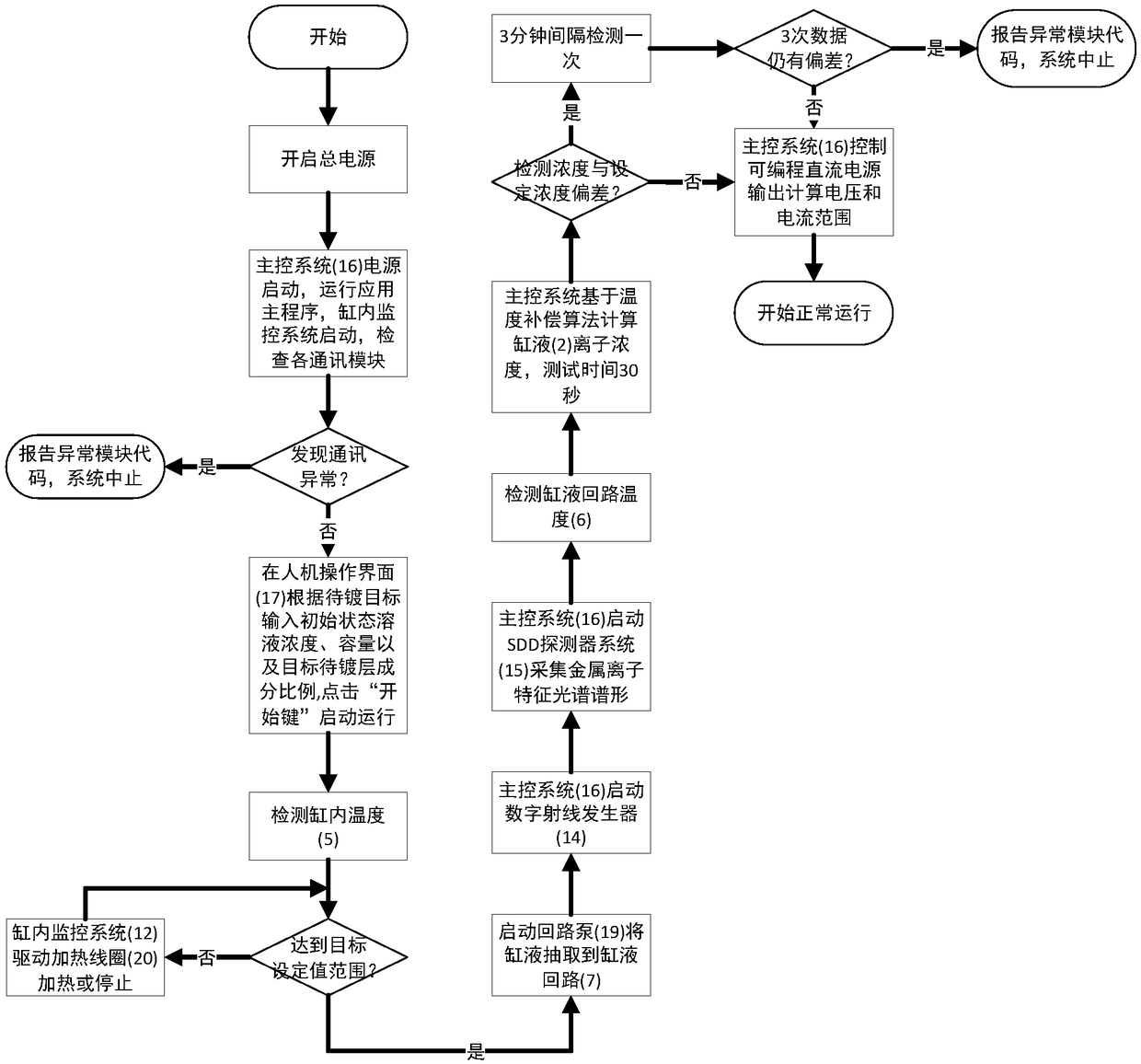

[0019] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0020] One aspect of the present invention provides a fully automatic control device for the composition of K gold electroforming coating, which is suitable for the precise control system of the composition of industrial electroforming and electroplating K gold.

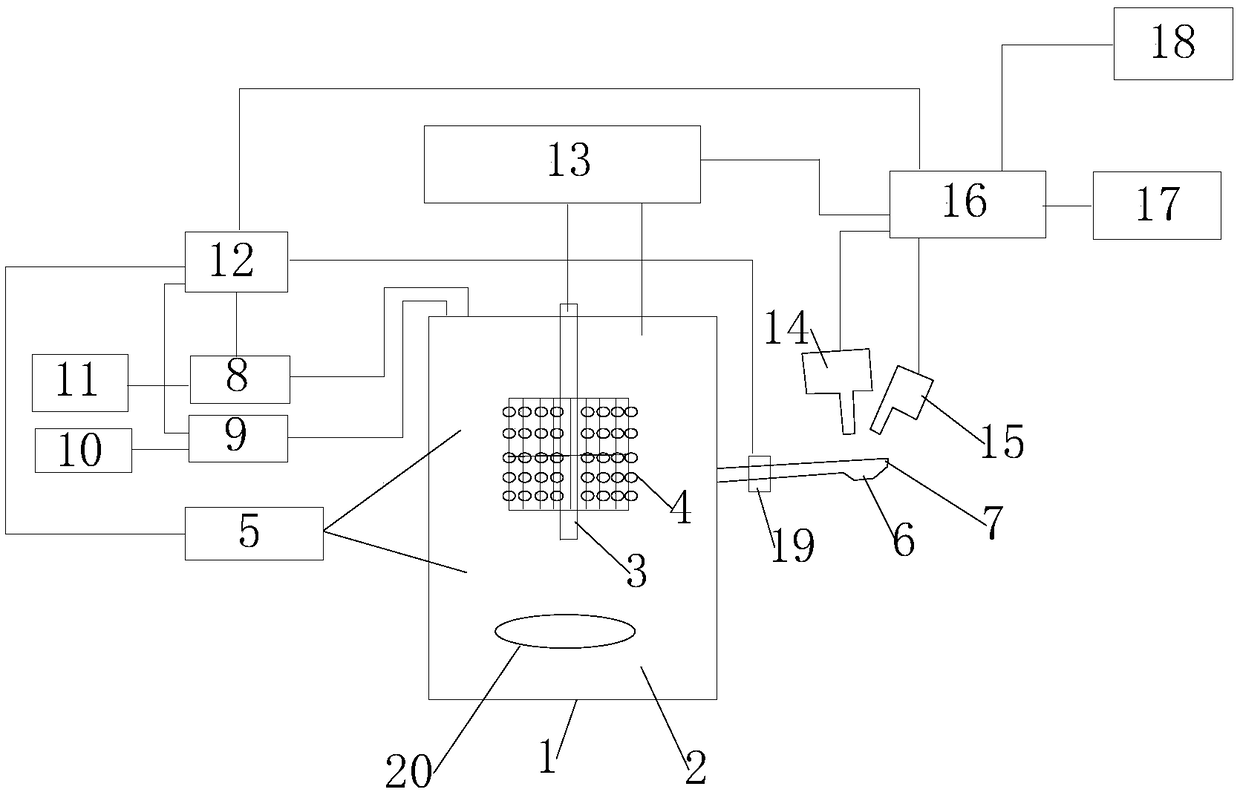

[0021] This K gold electroforming coating composition automatic control device comprises: feed pump 8,9, loop pump 7, digital ray generator 14, SDD detector 15, controller 16 and heating coil 20, described controller 16 controls described The digital ray generator 14 generates soft X-rays to irradiate the solution in the loop pump 7, the SDD detector 15 acquires the X-ray fluorescence characteristic spectrum produced by the metal ions in the solution, and the controller according to the X-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com