Automated optical inspection (AOI)-based bullet apparent defect detection method

A defect detection, bullet technology, used in optical testing flaws/defects, image data processing, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

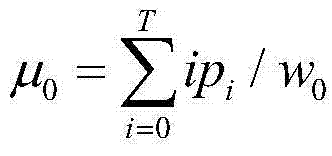

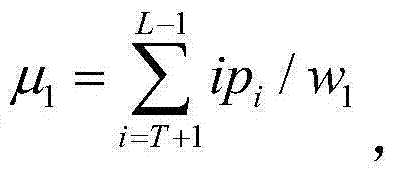

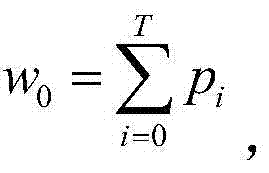

[0053] The AOI-based bullet apparent defect detection method, the specific steps are as follows:

[0054] (1) Use a CCD line array camera to shoot the surface of the bullet, make the bullet rotate at a constant speed along its axis, and rotate the CCD line array camera at least one circle, so as to obtain the initial grayscale image of the bullet surface; among them, the CCD line array camera A strip-shaped LED light source is installed at symmetrical positions on both sides to illuminate the surface of the bullet, and the camera acquires images along the axis of the bullet. The arrangement direction of the strip-shaped LED light source also matches the direction of the bullet axis, so that the side of the bullet facing the camera is fully illuminated , to avoid shadows affecting subsequent image recognition. As a preference, the CCD line scan camera adopts a 7400 pixel line scan camera.

[0055] (2) Due to various factors, some interference will inevitably appear on the init...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com