Electronic component surface defect detection method based on sample library dictionary

A technology for electronic components and defect detection, applied in the field of image processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention comprises the following steps:

[0043] Step (1) collecting qualified and defective electronic component images, and constructing an electronic component image sample library;

[0044] For electronic components that need to be tested for surface defects; select 200 qualified samples of the components, and at the same time select 100 samples of the components with air bubbles, damage, scratches and pins hanging under the paint on the surface;

[0045] (a) Place the sample device, LED lighting, and MER-030-120UC CCD industrial camera in a closed dark box, and collect the surface images of the above-mentioned qualified and defective electronic components;

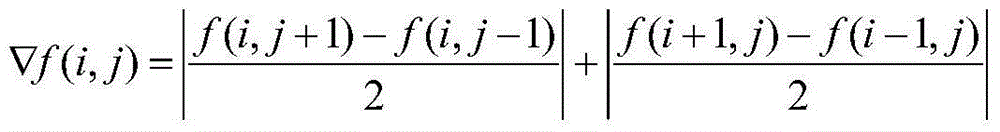

[0046] (b) Extract the gradient image ▽f from the collected image f as the characteristic image of each sample device as follows:

[0047] ▿ f ( i , j ) = | f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com