Lithium battery defect detection device based on battery temperature field and visible light image

A defect detection and battery temperature technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of environmental adaptability, poor performance, and the inability to improve the detection sensitivity of the detection device and the environmental adaptability, etc., to achieve The effect of improving efficiency and improving signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

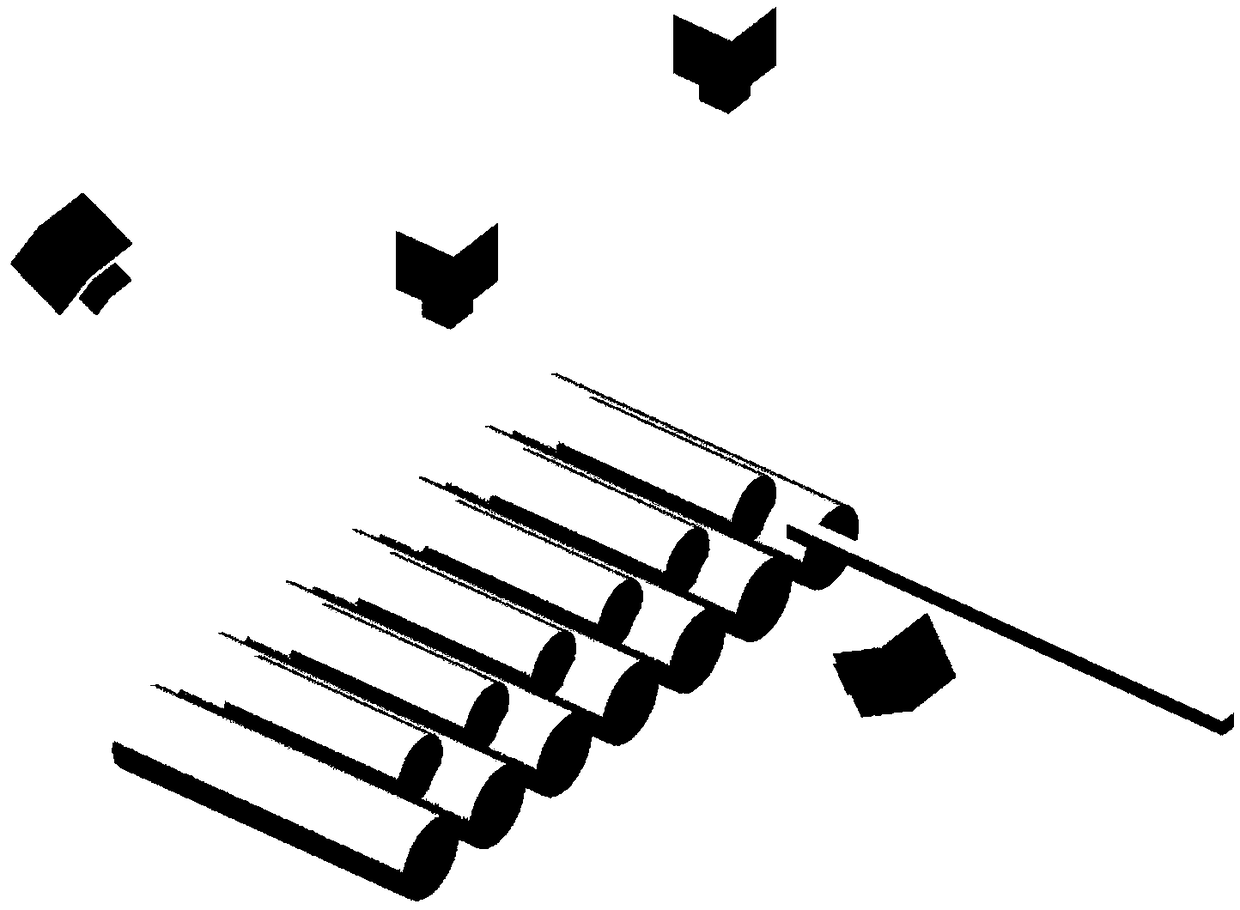

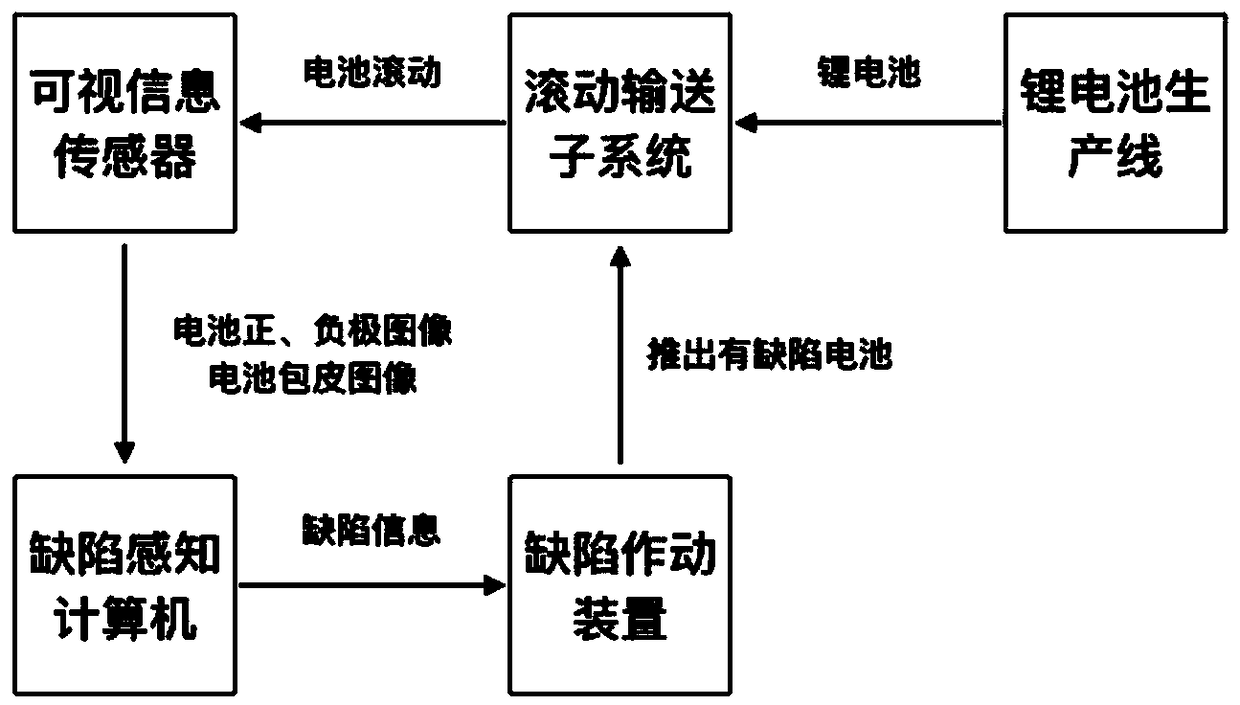

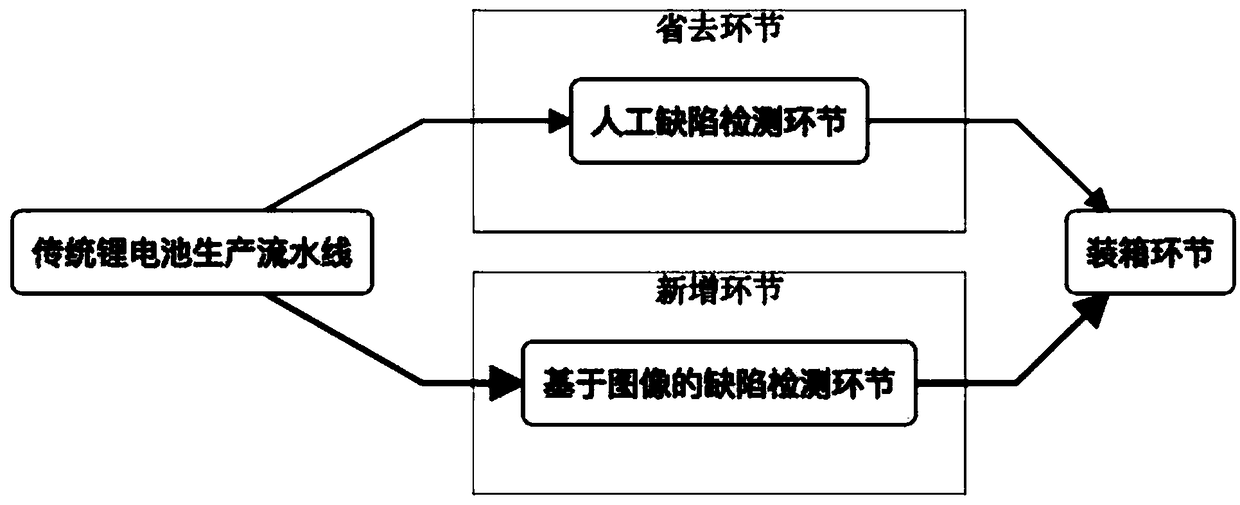

[0038] Such as Figure 1-2 As shown, the present invention is a lithium battery defect detection device based on the battery temperature field and visible light images, including a visual information sensor, a defect sensing computer, and a defect actuating device.

[0039] The visual information sensor consists of 3 to 4 industrial-grade high-definition pixel cameras and LED light sources. Among them, two sets are installed in series on the top of the conveying surface to keep 20% of the field of view overlapping, and one set is installed on each side of the conveyor belt. According to the lighting environment of the production line, select the appropriate shape of the light source and the installation position of the LED light source, so that the lithium battery delivery area can be evenly illuminated.

[0040] The defect-aware computer is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com