Eddy current detecting device used for performing metal defect detection and eddy current probe thereof

An eddy current probe and eddy current detection technology, which is applied to measuring devices, material analysis through electromagnetic means, instruments, etc., can solve the problems that restrict the detection efficiency and defects of the eddy current detection system, so as to improve the detection efficiency of defects, reduce interference and simplify The effect of hardware processing circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

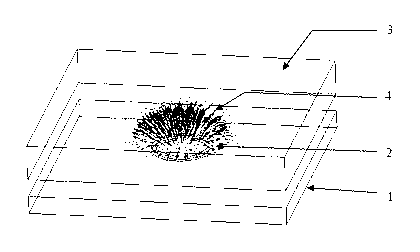

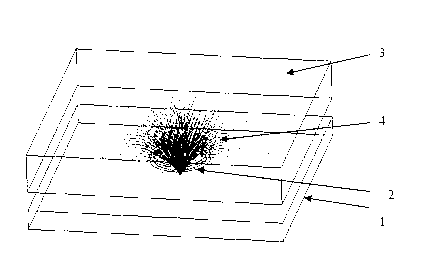

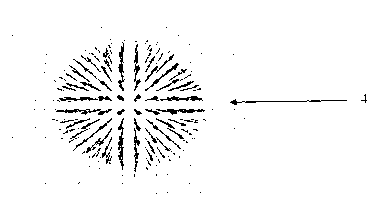

[0029] The structure of a vortex detection device of the present invention is like Figure 7 It shows that it includes the controller, the circuit of the signal, the filtering the amplifier circuit, the Xiangmin detecting circuit, the signal acquisition card, the upper machine, the first high -speed simulation switch, the second high -speed simulation switch, and the vortex probe of the present invention.Among them, the controller is connected with the signal incidence circuit, filtering circuit, the first high -speed simulation switch, and the second high -speed simulation switch connection.The output terminal is connected to the signal acquisition card, the signal acquisition card is connected to the upper machine, the signal incidence circuit is connected to the first high -speed simulation switch, and the filtering circuit is connected to the second high -speed simulation switch;Connect to the first high -speed simulation switch, each induction coil in the vortex probe is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com