Robot for all-bearing defect detection of large-capacity flat-bottom container bottom plate and detection method

A technology of flat-bottomed containers and robots, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of poor accuracy and low efficiency, and achieve the effects of improving detection accuracy, avoiding low feedback signal strength, and improving defect detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 Ultrasonic-based omnidirectional defect detection robot

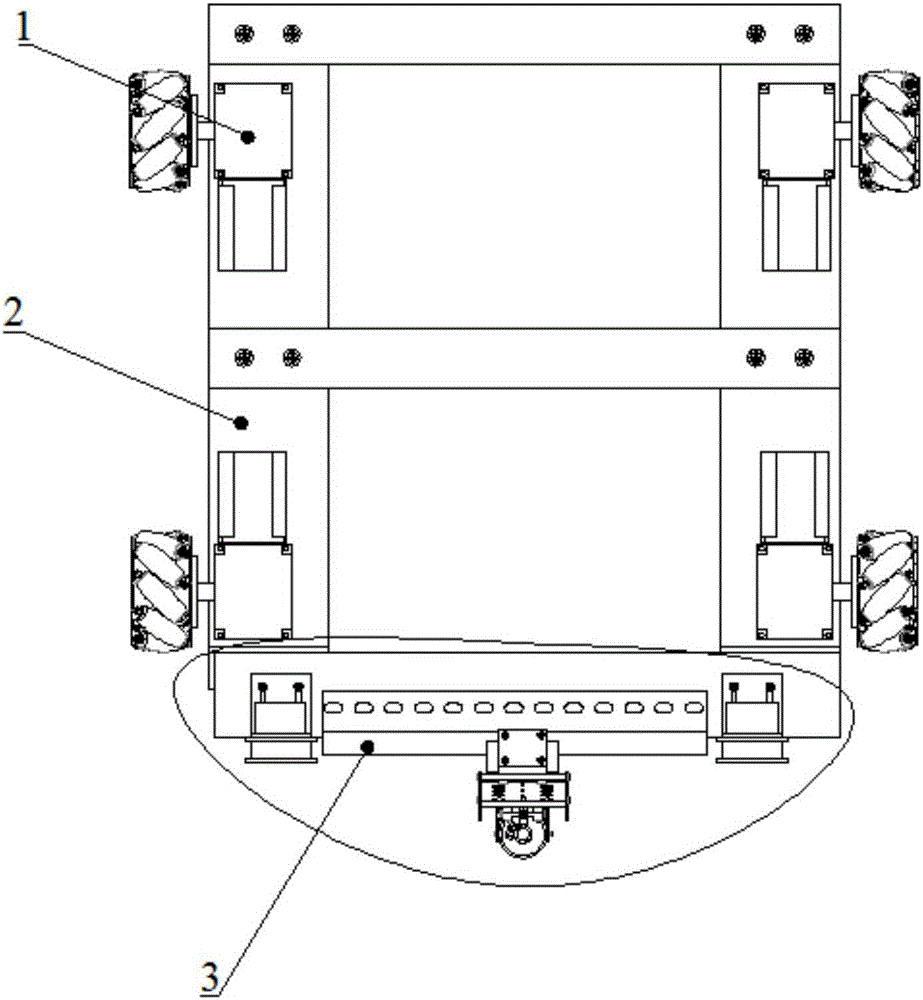

[0040] Such as figure 1 As shown, the ultrasonic-based robot construction components for omni-directional detection of large-volume flat-bottomed container bottom plate defects provided by this embodiment include a fuselage 2, a walking device 1 installed under the fuselage 2, and a robot installed at the end of the fuselage 2. Detection device 3.

[0041] The fuselage 2 is a rectangular vehicle frame formed by connecting four installation beams, the two sides are the installation beams for the traveling device, the front end is the installation beam for the detection device, and the middle beams are connected across the middle of the installation beams on both sides.

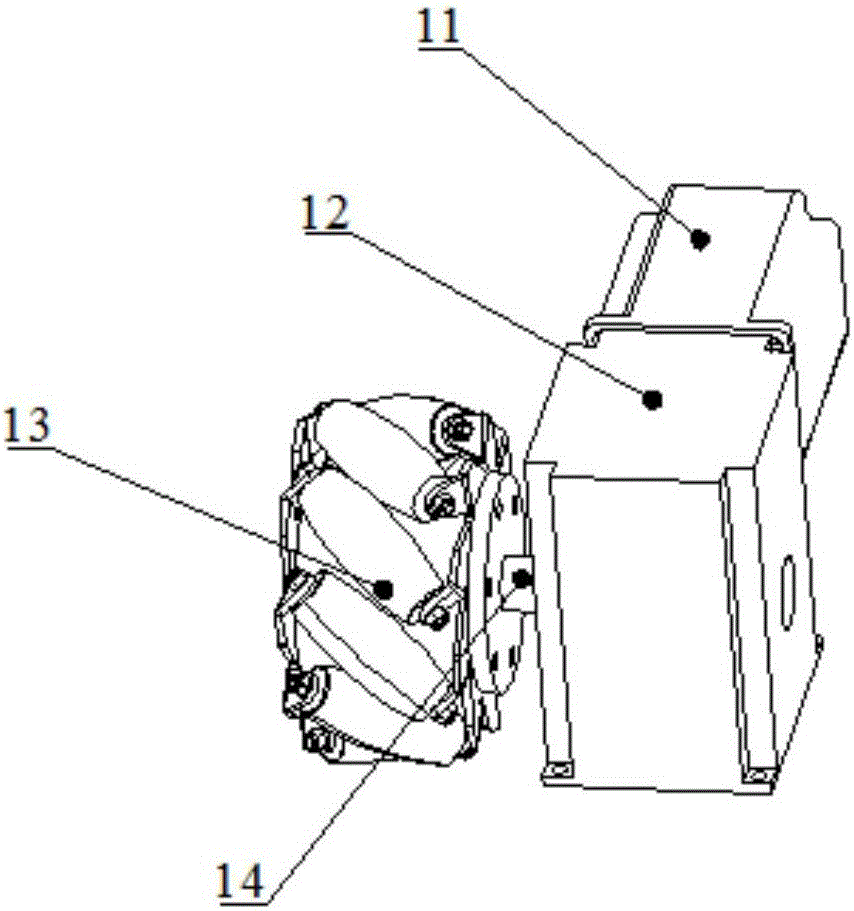

[0042] Such as figure 1 and figure 2 As shown, the running gear 1 is composed of four independently moving Mecanum wheel mechanisms mounted on the fuselage. Each Mecanum wheel mechanism is composed of a Mecanum wheel 13, a steppi...

Embodiment 2

[0046] Example 2 Defect position detection on the bottom plate of the oil storage tank

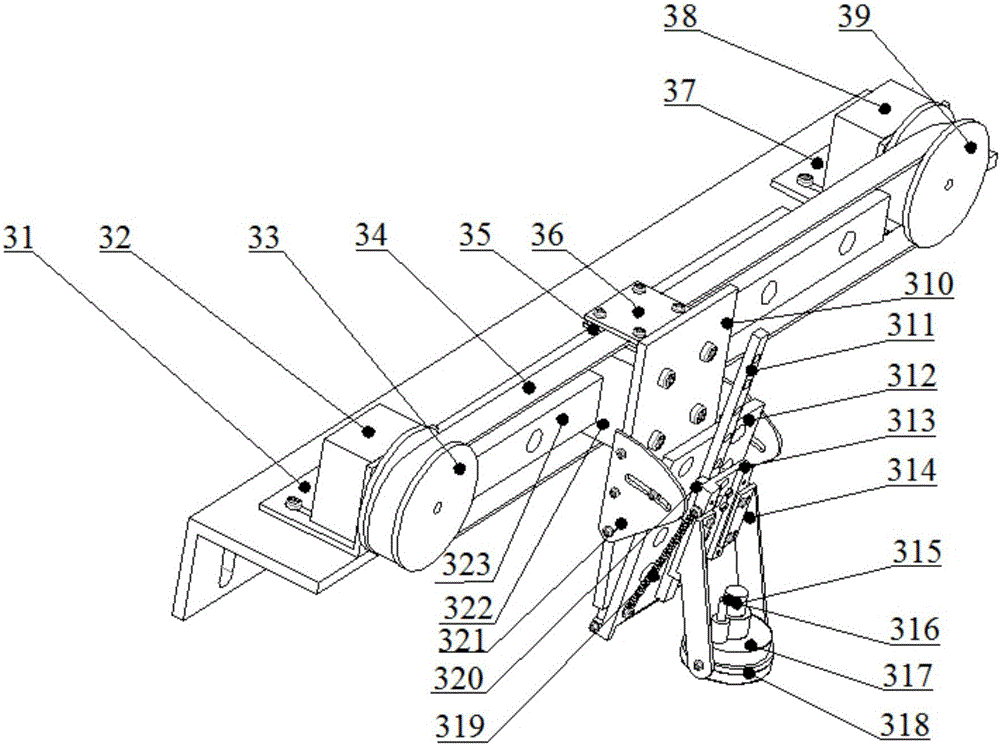

[0047] The above is the main structure of the robot. In order to realize the detection of the defect position, it is also necessary to configure a single-chip microcomputer for communication with the mecanum wheel 13, the stepper motor 11, the first motor 31, the second motor 38 and the ultrasonic probe 315. A detector that detects ultrasonic signals. The microcontroller used in this embodiment is Arduino Mega2560, and the detector used is SIUICTS-9009.

[0048] The defect detection method for detecting the bottom plate of the oil storage tank provided in this embodiment uses the robot in Embodiment 1, puts the robot on the bottom plate of the oil storage tank, adjusts the first slider 322 to the side of the first guide rail 323, and adjusts Rotate the adjustment plate 312 and the position of the second slider 320 on the second guide rail 311, so that the ultrasonic probe 315 is close to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com