Flaw detection method and device of printed circuit board and detection equipment

A printed circuit board and defect detection technology, applied in the field of inspection, can solve problems such as block edge effect and missed inspection, and achieve the effect of improving efficiency, improving defect detection efficiency and ensuring balance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

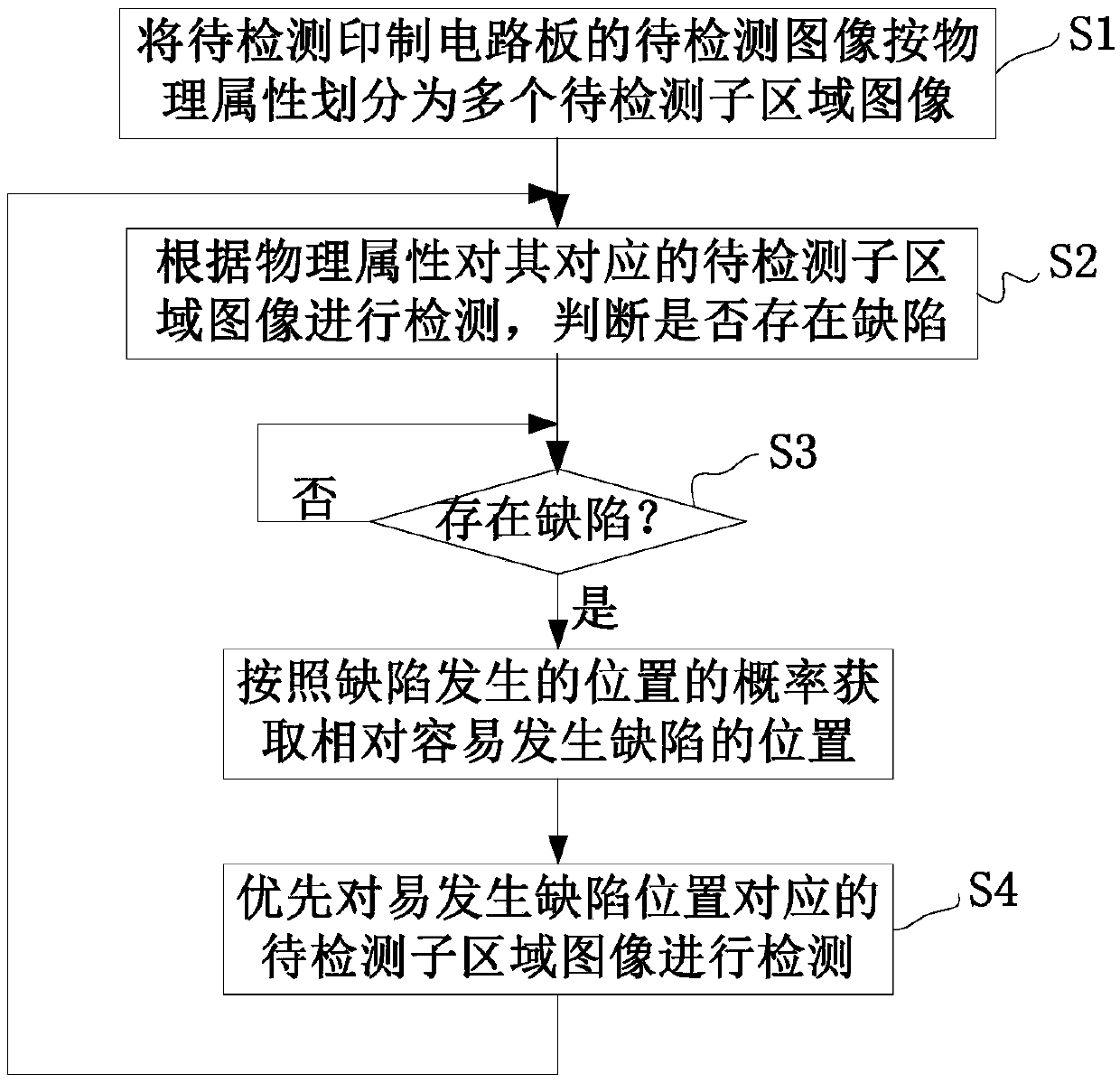

[0064] This embodiment provides a defect detection method for a printed circuit board, such as figure 2 shown, including the following steps:

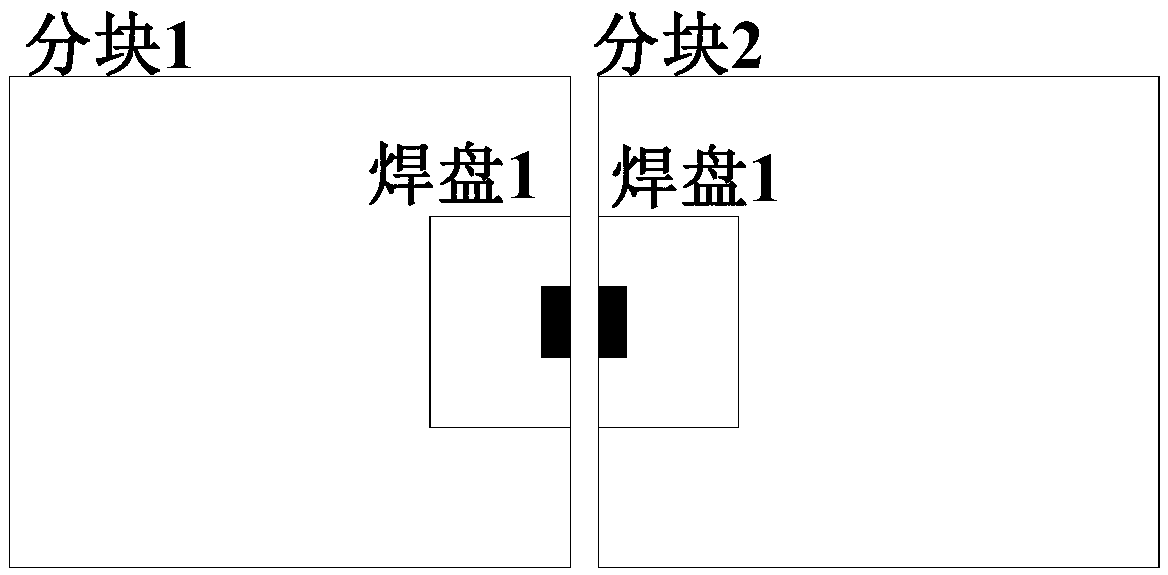

[0065] S1. Divide the image to be inspected of the printed circuit board to be inspected into a plurality of images of subregions to be inspected according to physical properties. By dividing the image to be detected of the printed circuit board to be detected into a plurality of sub-region images to be detected according to physical properties, the images corresponding to the same physical property in the printed circuit board to be detected can be located in the same sub-region image to be detected, Instead of being divided into two different sub-region images to be detected, resulting in missed detection due to block edge effects, the defect detection is more accurate.

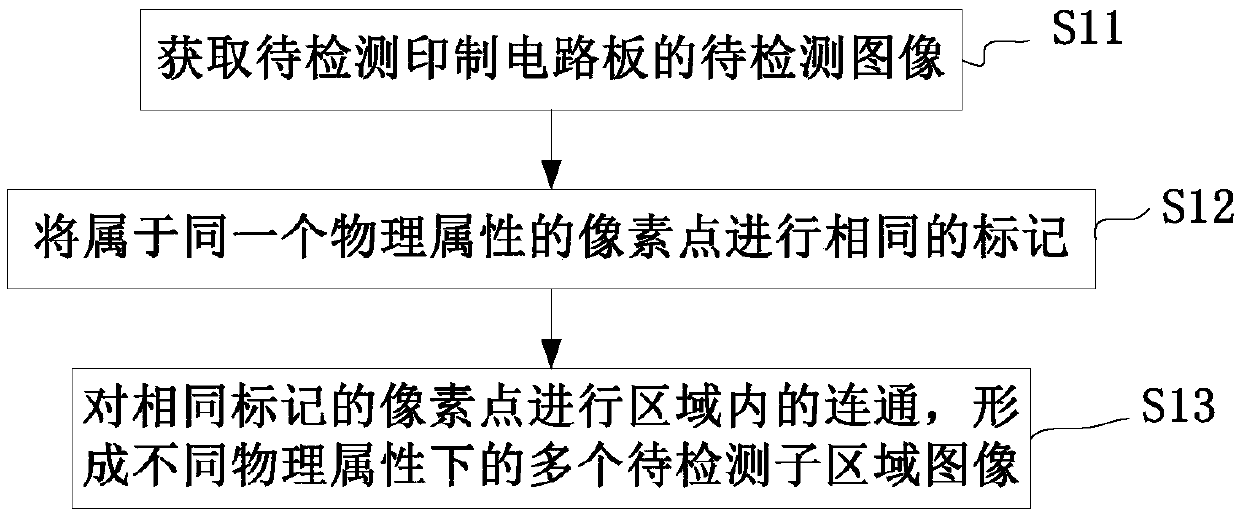

[0066] Preferably, as image 3 As shown, step S1 includes:

[0067] S11. Acquiring the image to be inspected of the printed circuit board to be inspected. Spec...

Embodiment 2

[0096] This embodiment provides a defect detection device for printed circuit boards, such as Figure 9 shown, including:

[0097] The area division unit 1 of the image to be inspected is used for dividing the image to be inspected of the printed circuit board to be inspected into a plurality of subarea images to be inspected according to physical properties.

[0098] Preferably, the image area division unit 1 to be detected includes:

[0099] The image to be inspected acquisition subunit 11 is configured to acquire an image to be inspected of the printed circuit board to be inspected.

[0100] The marking subunit 12 is configured to mark the pixels belonging to the same physical attribute in the image to be detected in the same way.

[0101] The connecting sub-unit 13 is used to connect the pixel points of the same mark in the region to form a plurality of sub-region images to be detected under different physical properties.

[0102] The defect judging unit 2 is configured...

Embodiment 3

[0117] This embodiment provides a detection device, such as Figure 10 shown, including:

[0118] The image acquisition device 5 is used to acquire images of the printed circuit board to be inspected. Specifically, the image acquisition device 5 may be a CCD camera, which has the advantages of high sensitivity, anti-glare, small distortion, small size, long life, and anti-vibration.

[0119] The image processing device 6 is connected with the image acquisition device 5, and is used for digitizing and preprocessing the image, and outputting the image to be inspected of the printed circuit board to be inspected. Specifically, the image processing device 6 may be an image acquisition card. Preprocessing may include filtering out noise interference, contrast enhancement, edge enhancement, etc., to improve the clarity of the image to be detected.

[0120] The detection parameter acquiring device 7 is used to acquire the detection parameters for detecting the image to be detected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com