Fruit surface defect detection method based on image marking

A defect detection and image marking technology, which is applied in the direction of optical defect/defect testing, measuring devices, and material analysis through optical means, can solve problems such as insufficient practicability, reduce labor intensity and error rate, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

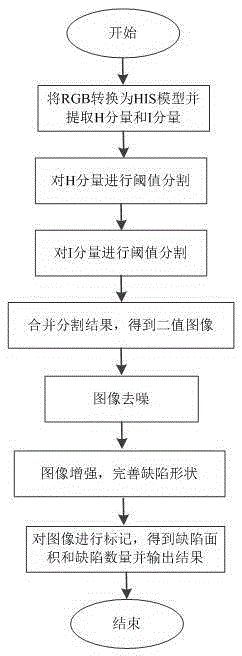

[0039] The present invention is a method for detecting fruit surface defects based on image marking, taking first-class apples (without defects) as an example to be tested, see figure 1 , 2 , including the following steps:

[0040] 1) The user uses the image acquisition device to take a photo of the surface of the apple to be detected on the spot and save it to obtain the original image;

[0041] 2) The user uploads the original picture to be tested to the Apple surface defect detection server through wireless or wired means, and the server analyzes the original picture and outputs the result;

[0042] Such as figure 1 As shown, the processing steps of the server include:

[0043] a. Convert the acquired original image from the RGB space to the HSI color space described by the human visual system, using hue (Hue), color saturation (Saturation) and brightness (Intensity), and extract the H component and I component ;

[0044] b. Use the OSTU maximum inter-class variance ...

Embodiment 2

[0067] Take an apple with two defects on the surface as an example to be tested, see figure 1 , 2 , including the following steps:

[0068] 1) The user uses the image acquisition device to take a photo of the surface of the apple to be detected on the spot and save it to obtain the original image;

[0069] 2) The user uploads the original picture to be tested to the Apple surface defect detection server through wireless or wired means, and the server analyzes the original picture and outputs the result;

[0070] Such as figure 1 As shown, the processing steps of the server include:

[0071] a. Convert the acquired original image from the RGB space to the HSI color space described by the human visual system, using hue (Hue), color saturation (Saturation) and brightness (Intensity), and extract the H component and I component ;

[0072] b. Use the OSTU maximum inter-class variance method for the H component to perform dynamic threshold segmentation;

[0073] c. Perform s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com