Construction method of double shear wall formworks at deformation joint of high-rise building

A construction method and technology for high-rise buildings, applied to the processing of building materials, formwork/formwork/work frame, and on-site preparation of building components. It can solve problems such as damage and cracks, achieve quality control, save construction costs, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

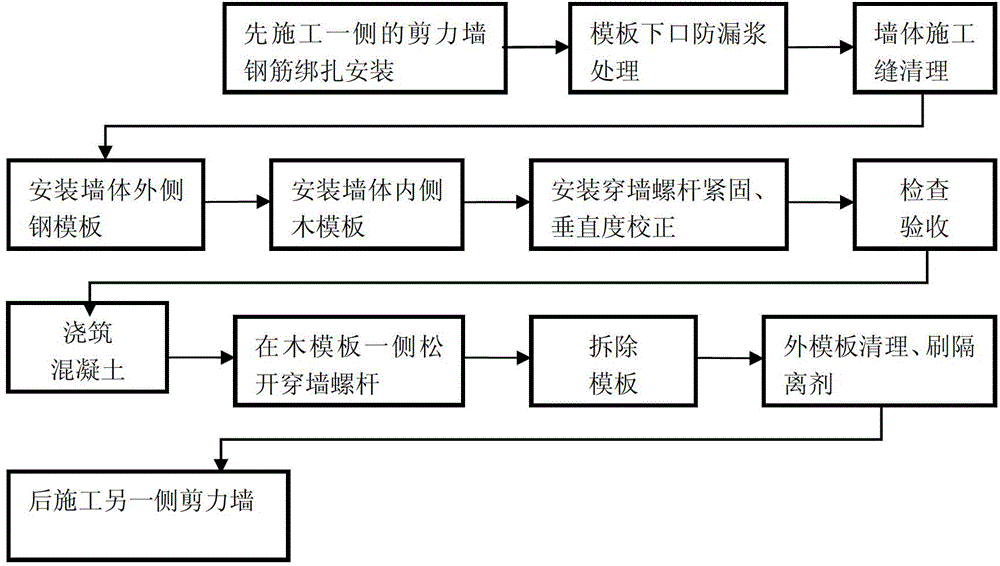

[0041] A construction method for a double shear wall formwork at a deformation joint of a high-rise building, comprising the following steps:

[0042] step 1

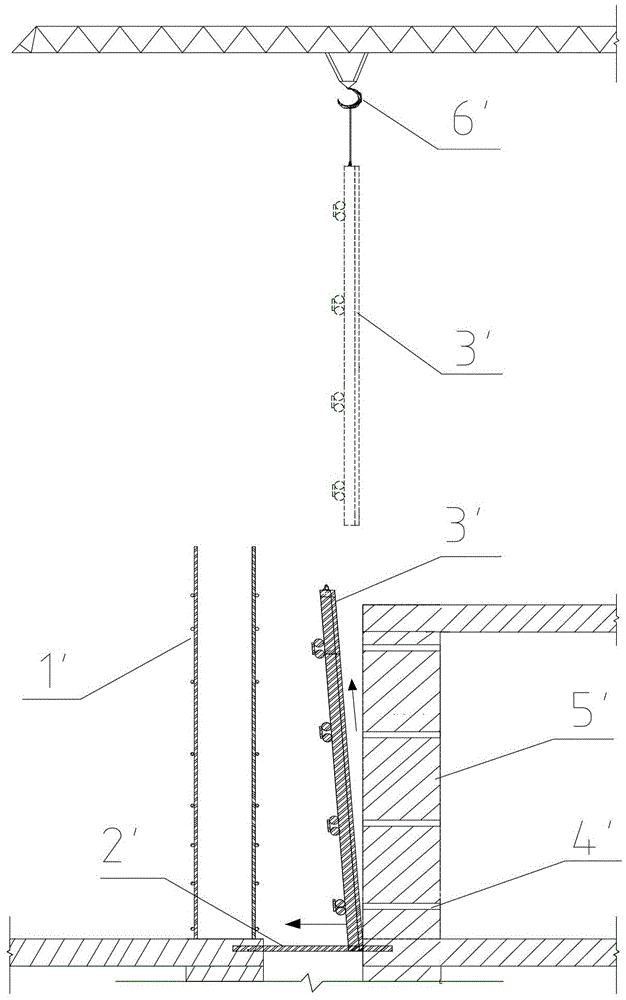

[0043] First construct the shear wall on one side of the deformation joint, bind the steel skeleton for 1', carry out anti-leakage treatment on the sticky sponge strip at the bottom of the formwork, and set up multiple horizontally at the position of the shear wall to be poured at the bottom of the deformation joint to support the outer formwork the supporting steel bar 2', use the tower crane 6' to vertically place the outer formwork 3' on the supporting steel bar;

[0044] Step 2

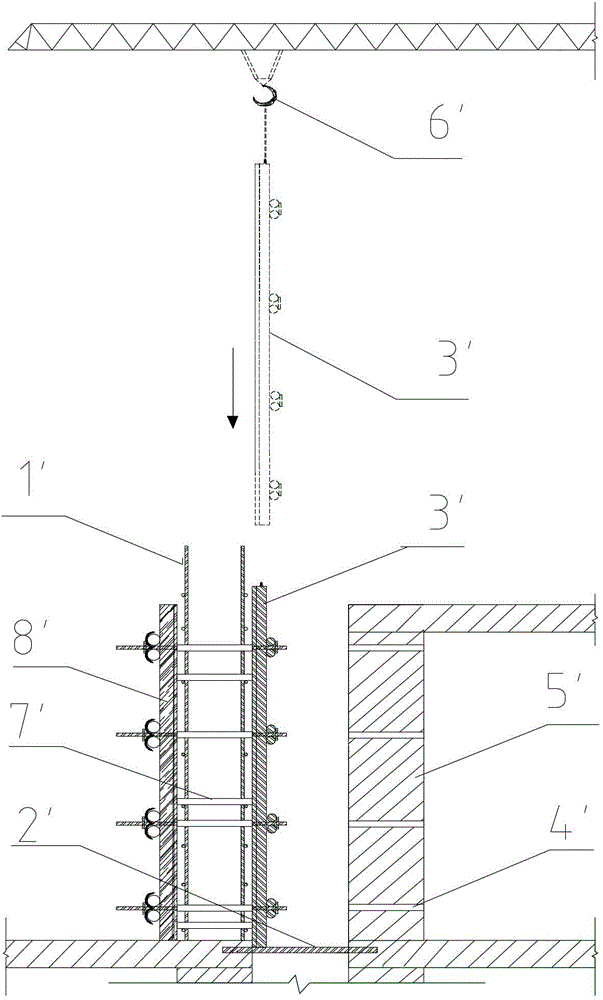

[0045] After the outer formwork 3' is temporarily in place, the inner formwork 8' is hoisted to the working floor by a tower crane, so that the inner formwork 8' and the outer formwork 3' are relatively parallel to each other, and the steel skeleton 1' is located inside and outside. Between the formwork; then fix the outer formwork 3' and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com