Intelligent production cycle assembly line for cyanuric acid

An assembly line, cyanuric acid technology, applied in the direction of organic chemistry, can solve the problems of uneven heating, low efficiency, physical health injury of operators, etc., to save the operation time, realize the cycle operation, and save labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

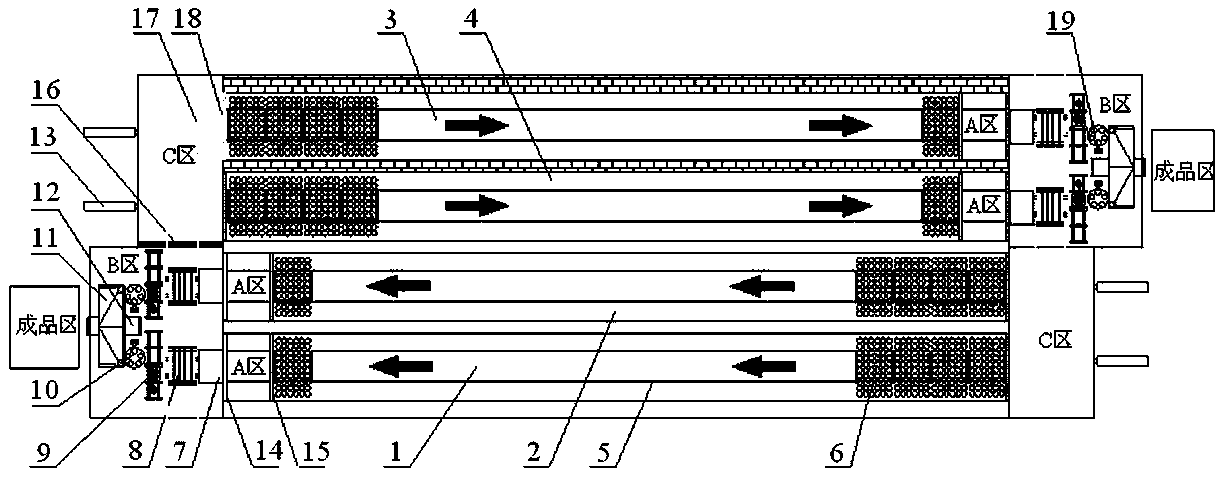

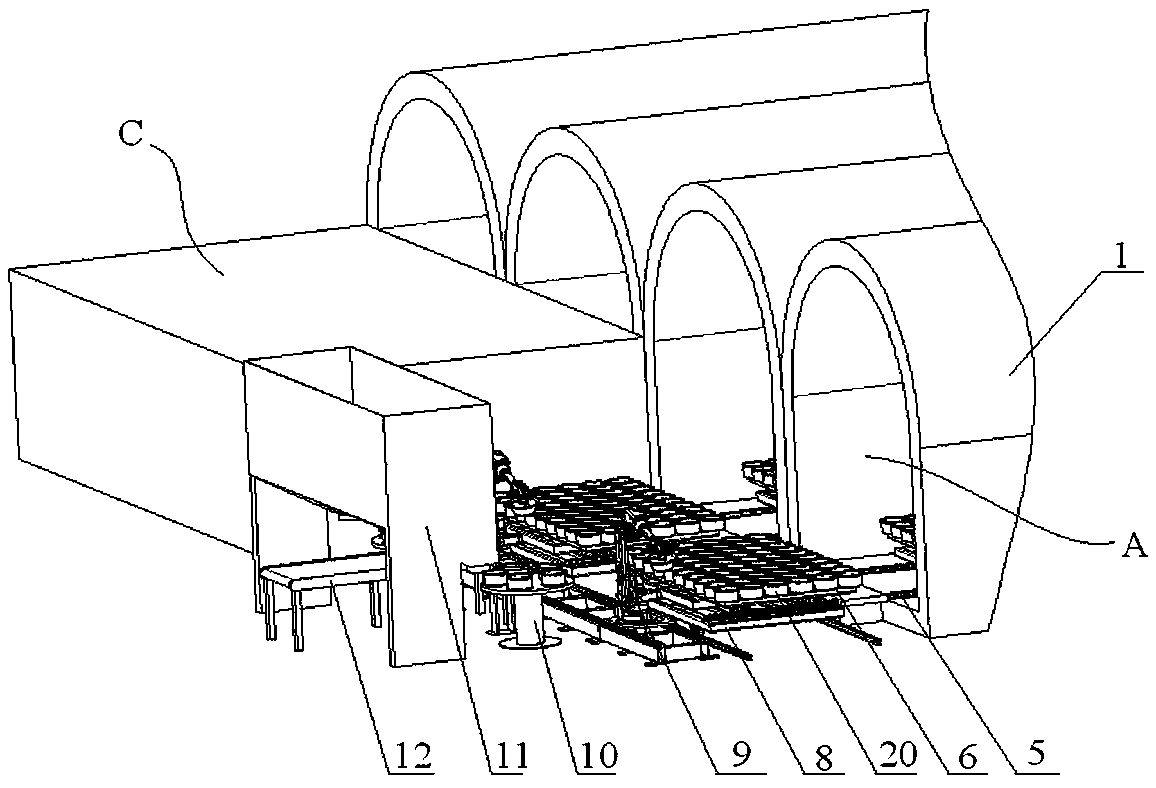

[0019] A kind of cyanuric acid intelligent production circulation line, its structure is as follows figure 1 and figure 2 As shown, it includes four kilns arranged side by side. Kiln I to Kiln IV are all used for heating materials. There are kiln guide rails 5 and driving devices in the kiln, and the trolley 6 with materials placed there is driven by the driving device. Walk from one end of the kiln to the other end of the kiln on the guide rail of the kiln to complete the heating process. In the present invention, a plurality of material basins 20 for placing materials are placed side by side in a single layer on the trolley, and the trolleys are arranged without intervals in the kiln to ensure that the materials are heated evenly and improve product quality.

[0020] In this embodiment, the trolleys in kiln I1 and kiln II2 move i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com