Patents

Literature

173 results about "Loop pipelining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for ultrasonically detecting weld quality of main loop pipeline of nuclear power plant by phased array

ActiveCN103336055AHigh-precision detectionEasy to adjustAnalysing solids using sonic/ultrasonic/infrasonic wavesOperational systemNuclear power

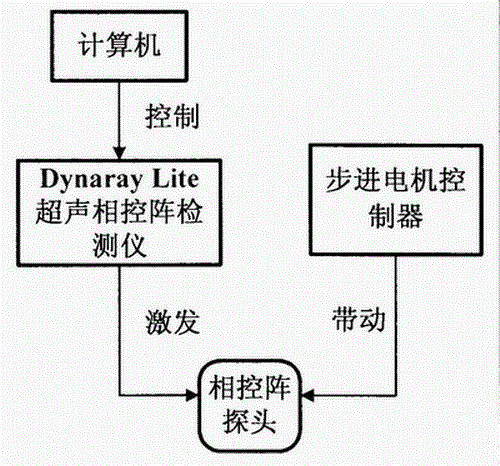

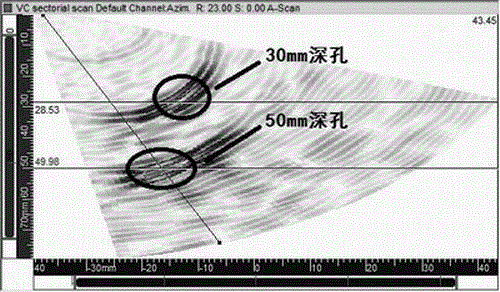

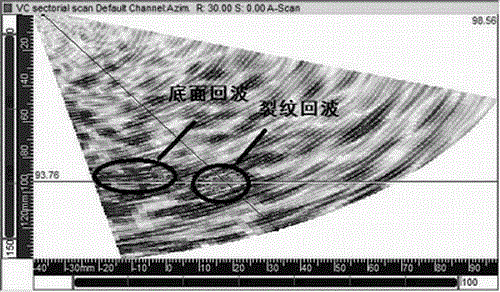

The invention discloses a method for ultrasonically detecting the weld quality of a main loop pipeline of a nuclear power plant by a phased array and belongs to the technical field of ultrasonic non-destructive detection and evaluation. According to the method, a phased array ultrasonic test system composed of a Dynaray Lite ultrasonic phased array tester, an integrated UltraVision3.2R9 phased array operation system, a scanning device and a calibration block is adopted. Aiming at the main pipeline having a thickness of 66-99 mm, a proper area array probe is selected, and a focusing principle parameter, an ultrasonic parameter and a mechanical parameter are matched, so as to perform layered detection on a weld of the main pipeline and the peripheral region. Layered permeation in the existing means for detecting the main pipeline is only capable of detecting the surface open defects of the weld; radiographic detection is incapable of quantifying defect depths and insensitive to area defects such as cracks and incomplete fusion; and the conventional ultrasonic detection technology has the defects of being low in detection efficiency, high in cost, low in imaging capacity and the like. The method disclosed by the invention overcomes the defects is good in quantifying accuracy and high in efficiency in field detection, and has great economic benefits and social benefits.

Owner:DALIAN UNIV OF TECH +2

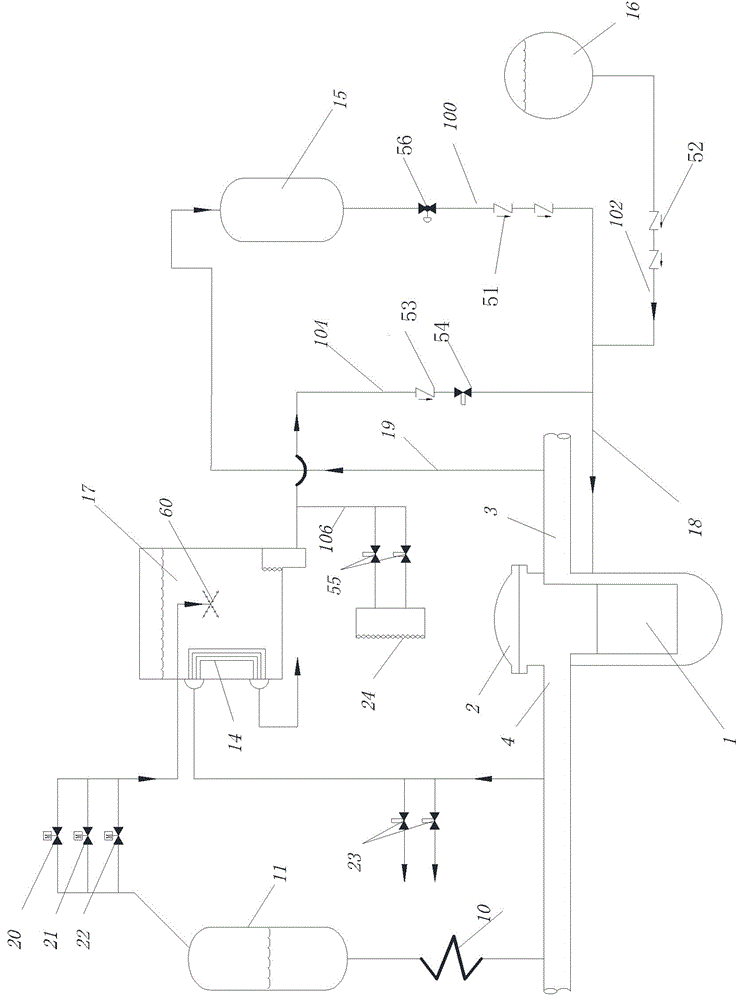

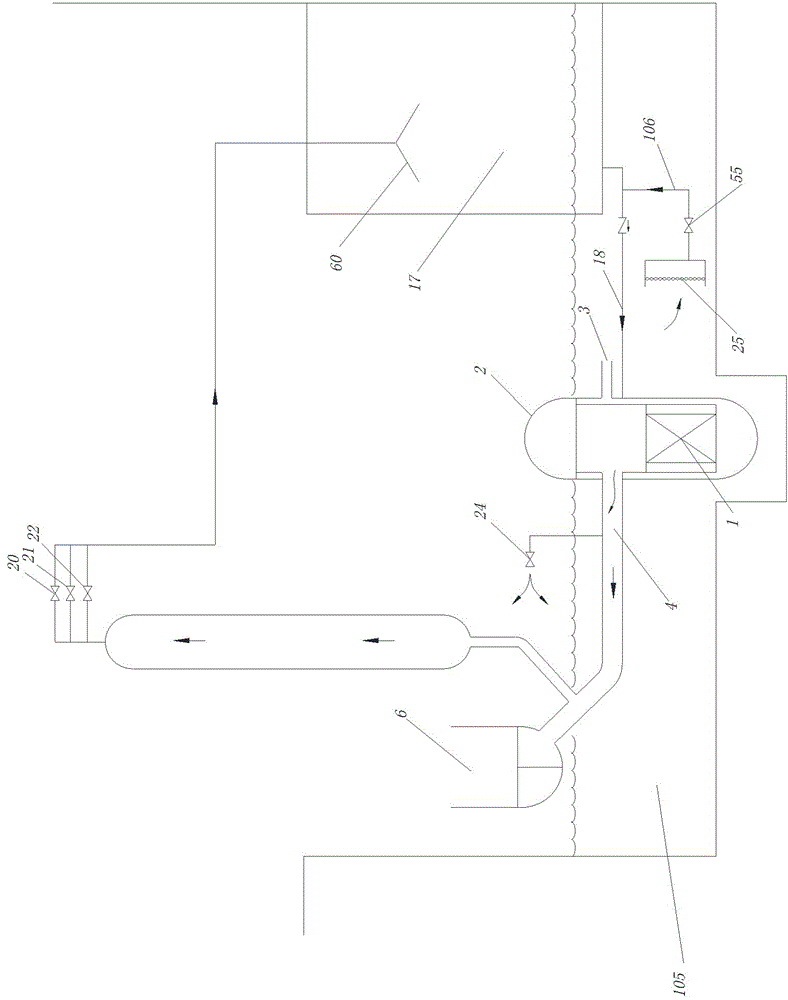

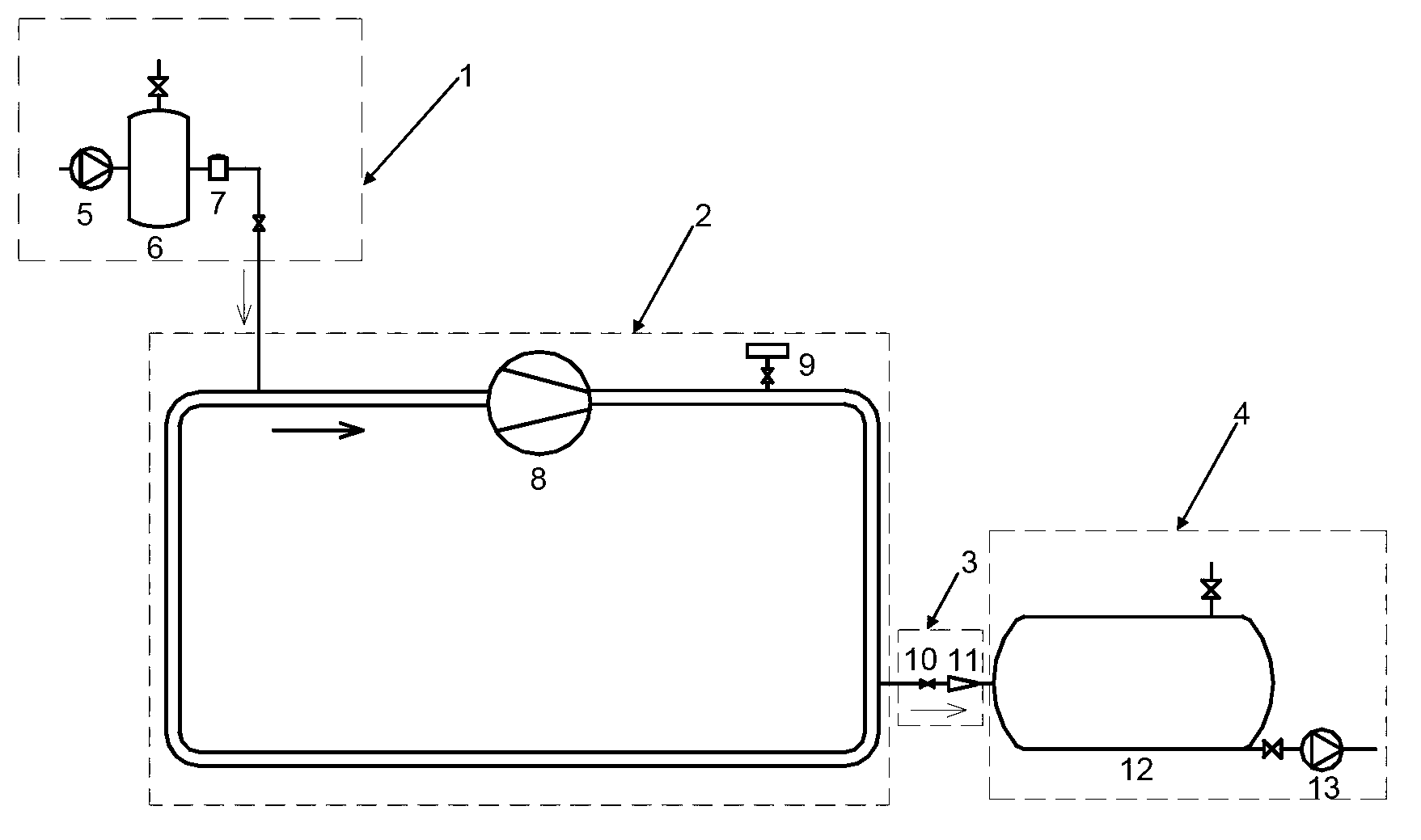

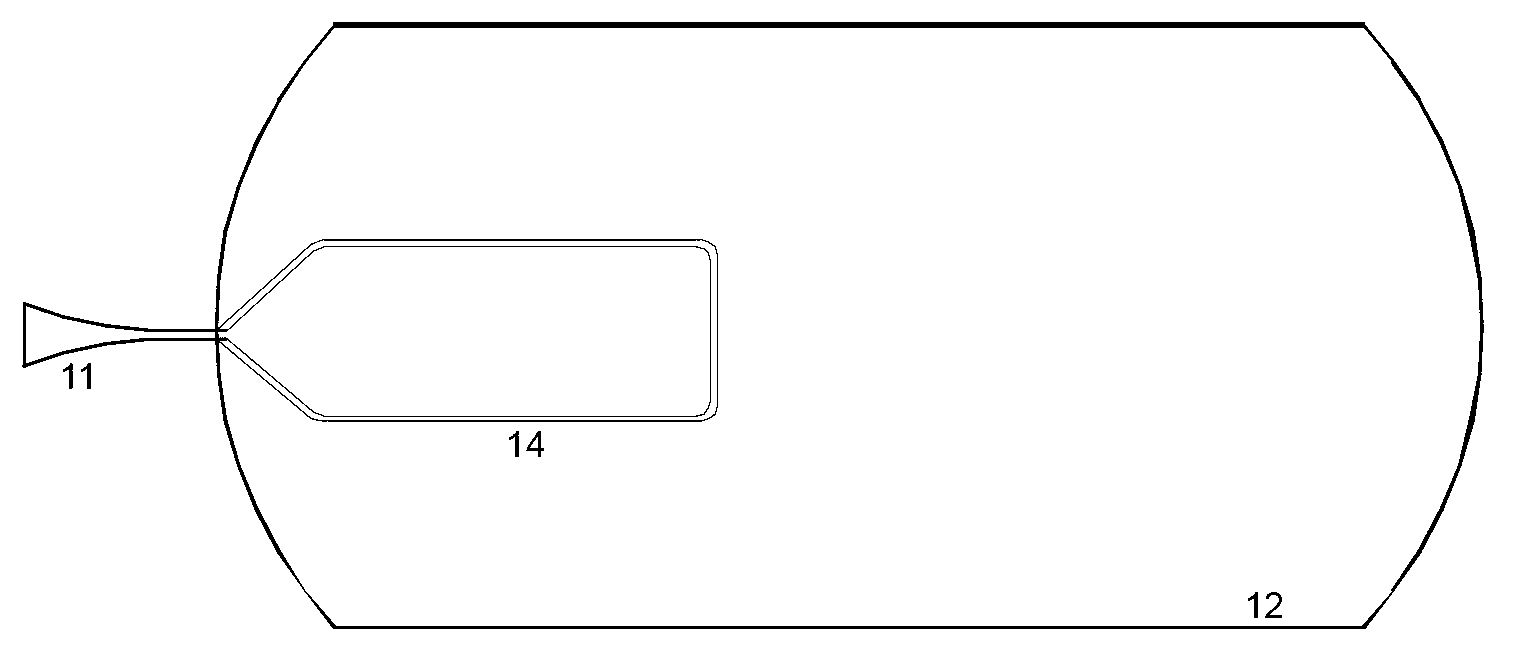

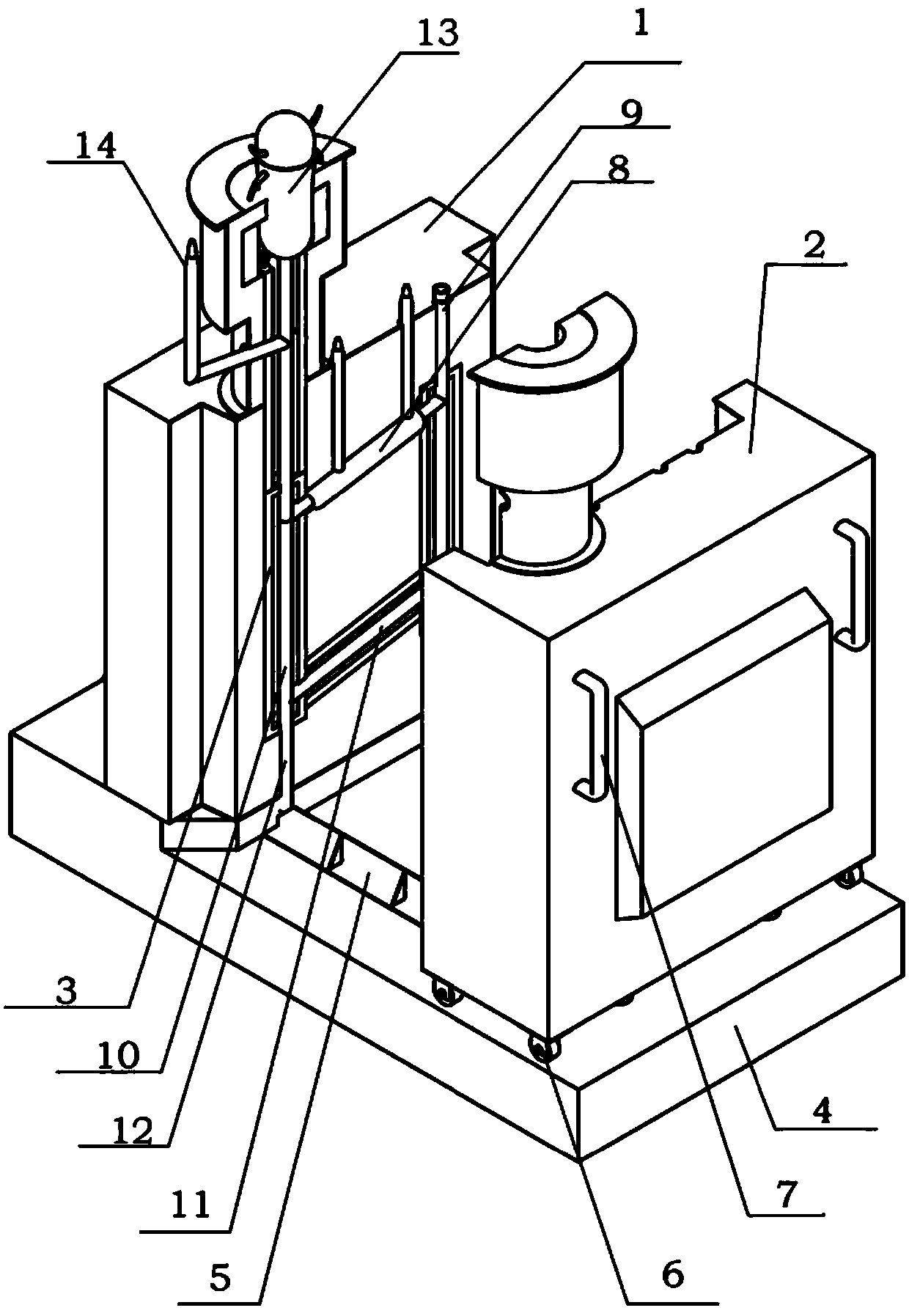

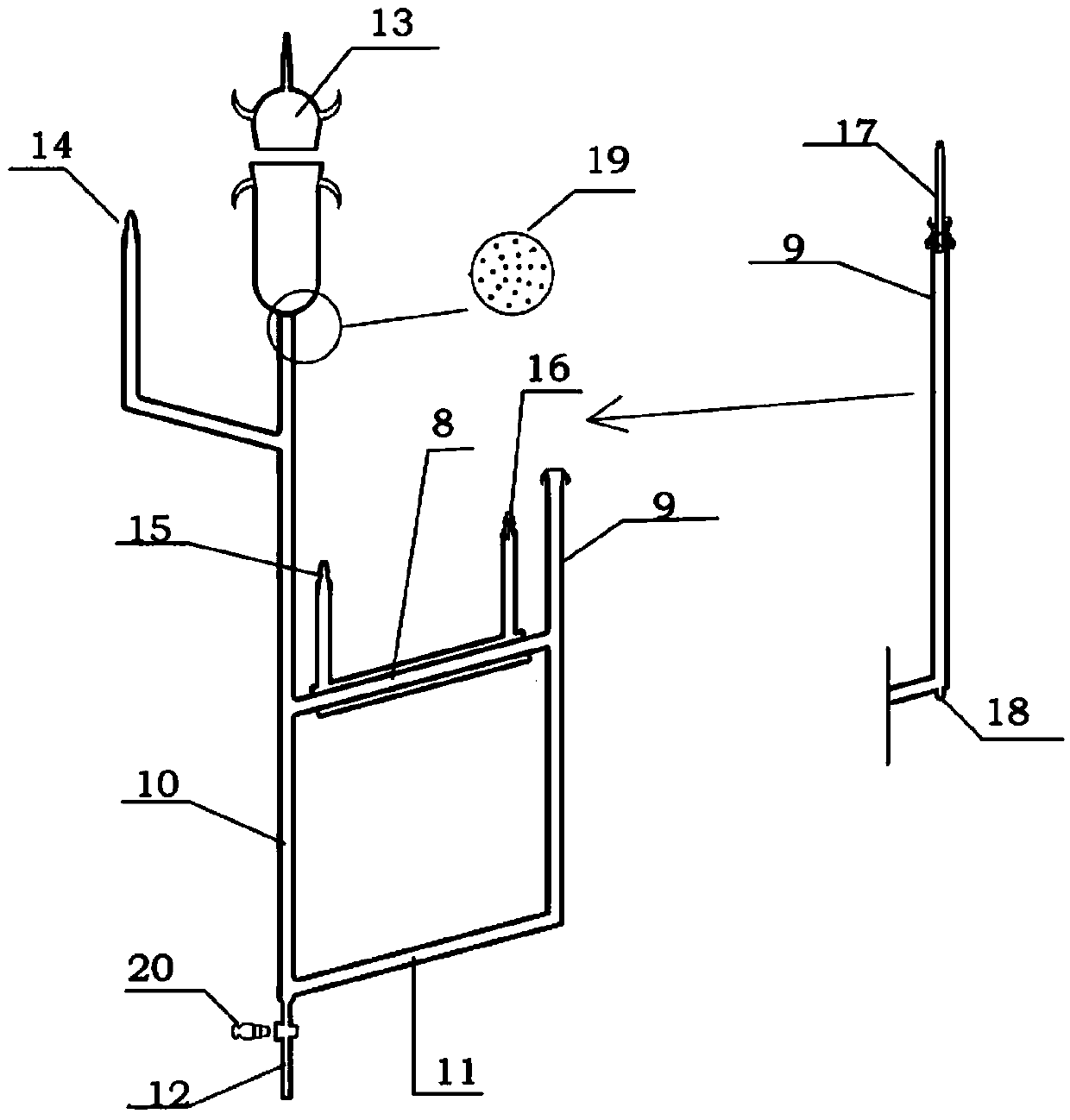

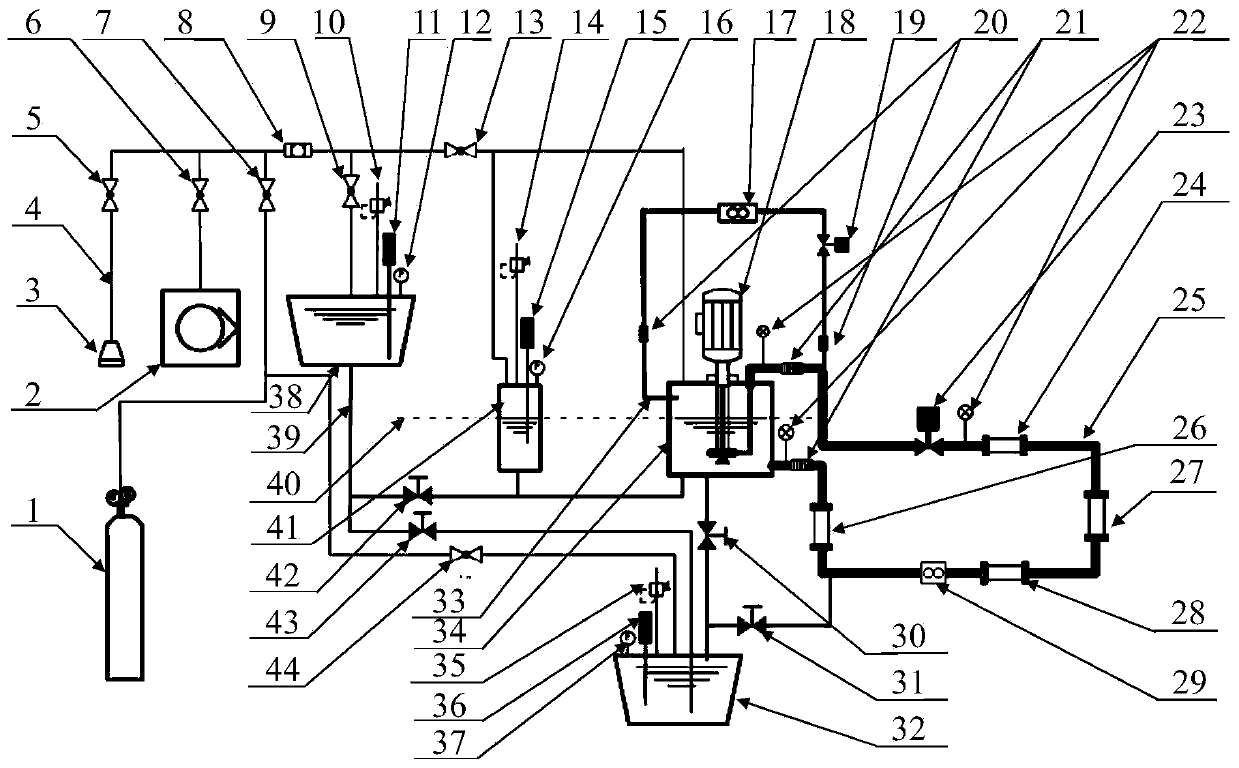

Supercritical Freon heat exchange experiment system and experiment method thereof

ActiveCN105301047AVersatileSimple and reliable structureMaterial heat developmentEngineeringHigh pressure

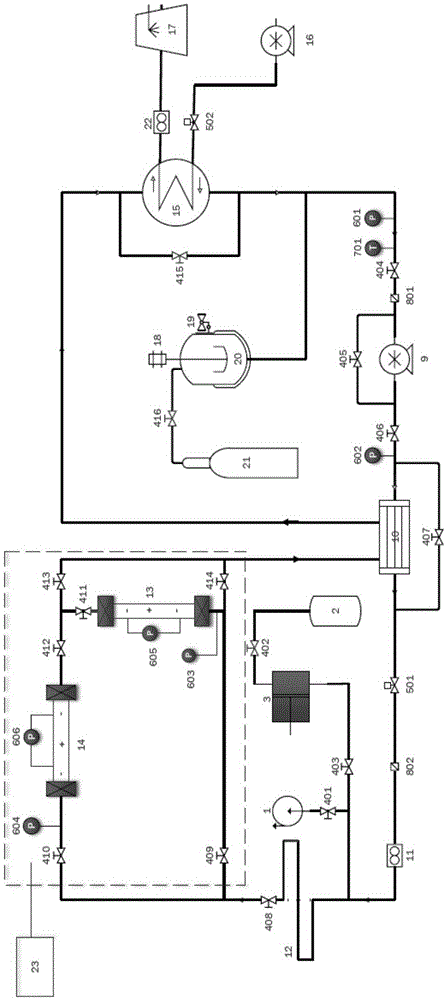

The invention discloses a supercritical Freon heat exchange experiment system and an experiment method thereof. The system comprises a vacuum and Freon injection module consisting of a vacuum pump, a coolant tank, a coolant recycling and injection machine, a valve and a pipeline connected to a main loop, a circulating module consisting of a shield pump and a closed type loop pipeline, a heat return module consisting of a heat regenerator and a bypass pipeline, a preheating module consisting of a snake-shaped preheating section and a direct current power supply, an experiment module consisting of an experiment section and a relevant valve, and a pressure adjustment module consisting of a high-pressure nitrogen bottle, a pressure stabilizer, a safety valve and a pressure reduction valve, wherein Freon flows into the experiment section after being subjected to heat regeneration and preheated from the outlet of the shield pump, and then finally returns to the inlet of the shield pump after being cooled by a condenser, thus forming a closed circulation. The invention further provides an experiment method of the system. The system can bear a higher-temperature working condition and a higher-pressure working condition, ensure that the Freon can run cyclically under a supercritical state, and also easily, conveniently and quickly adjust system parameters.

Owner:XI AN JIAOTONG UNIV

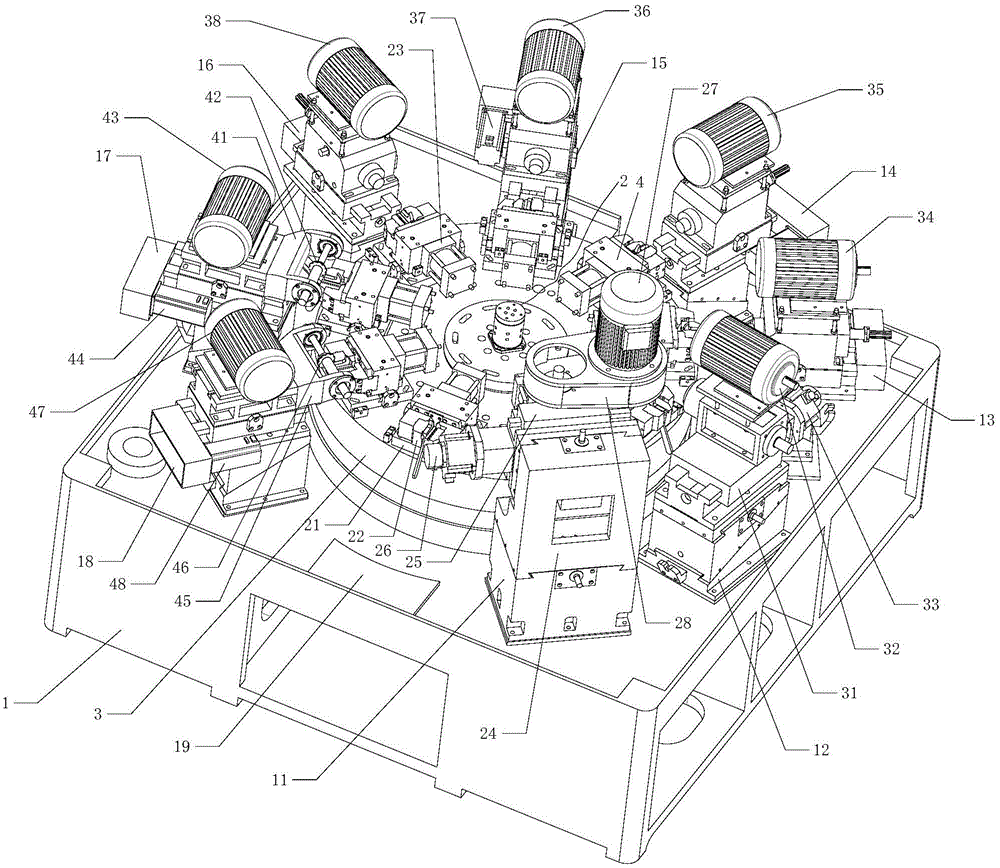

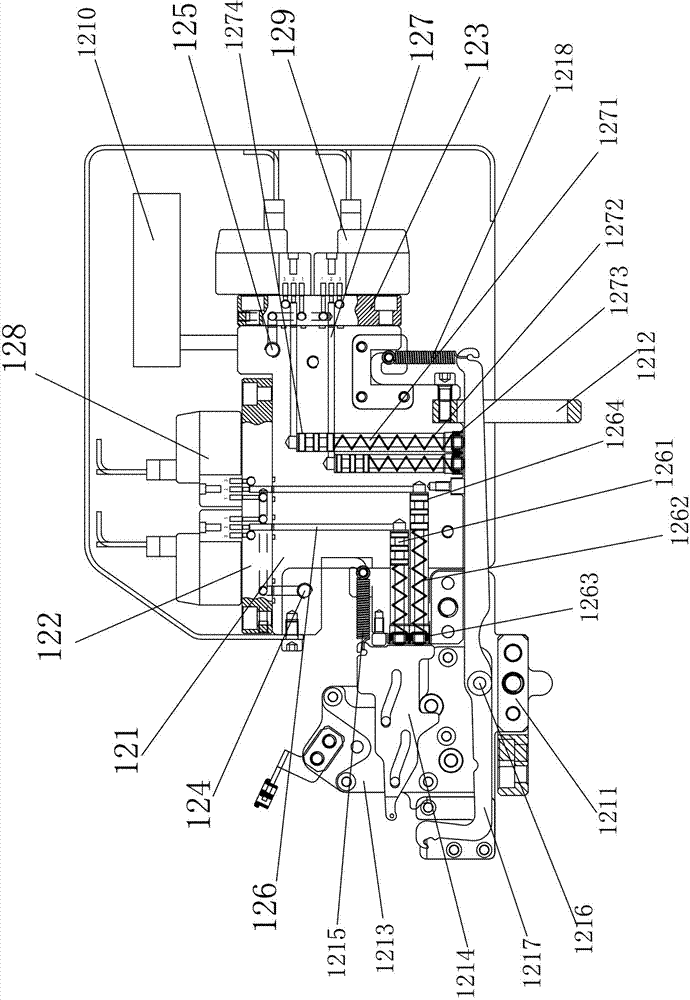

Automatic spanner processing device

InactiveCN104647046AReasonable structureReduce labor intensityPrecision positioning equipmentOther manufacturing equipments/toolsAssembly lineOperation mode

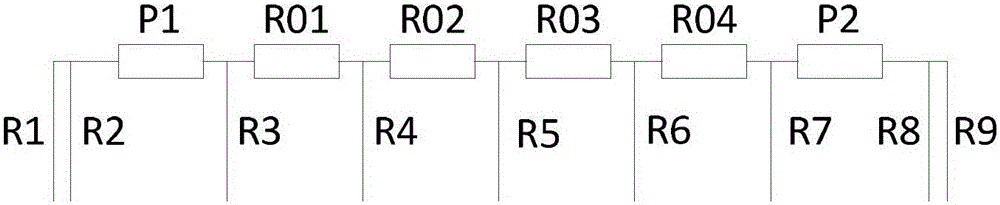

The invention is applicable to the technical field of precision part processing equipment and discloses an automatic spanner processing device. The device comprises a worktable, a dividing head arranged at the center of the worktable, a rotating disc arranged on the dividing head, and nine workpiece clamps which are fixedly connected with the rotating disc, wherein a milling surface mechanism, a positioning mechanism, a first drilling mechanism, a second drilling mechanism, a first milling groove mechanism, a second milling groove mechanism and a feeding station are arranged on the worktable at the periphery of the rotating disc. The automatic spanner processing device provided by the invention is reasonable in structure, so that the operation which can be finished by several machines operated by four or five persons before can be finished by the machine operated by only one person now, the labor intensity of workers is greatly reduced, and the labor cost is reduced. Moreover, with the adoption of the operation mode of the dividing head and nine station cycle assembly lines, the consumption of electric energy is reduced by at least 40 percent, the loss of tools and molds can be obviously reduced, and the precision and quality of the finished products are high due to arrangement of multiple drilling stations.

Owner:海盐县澉浦南洋纺器配件厂

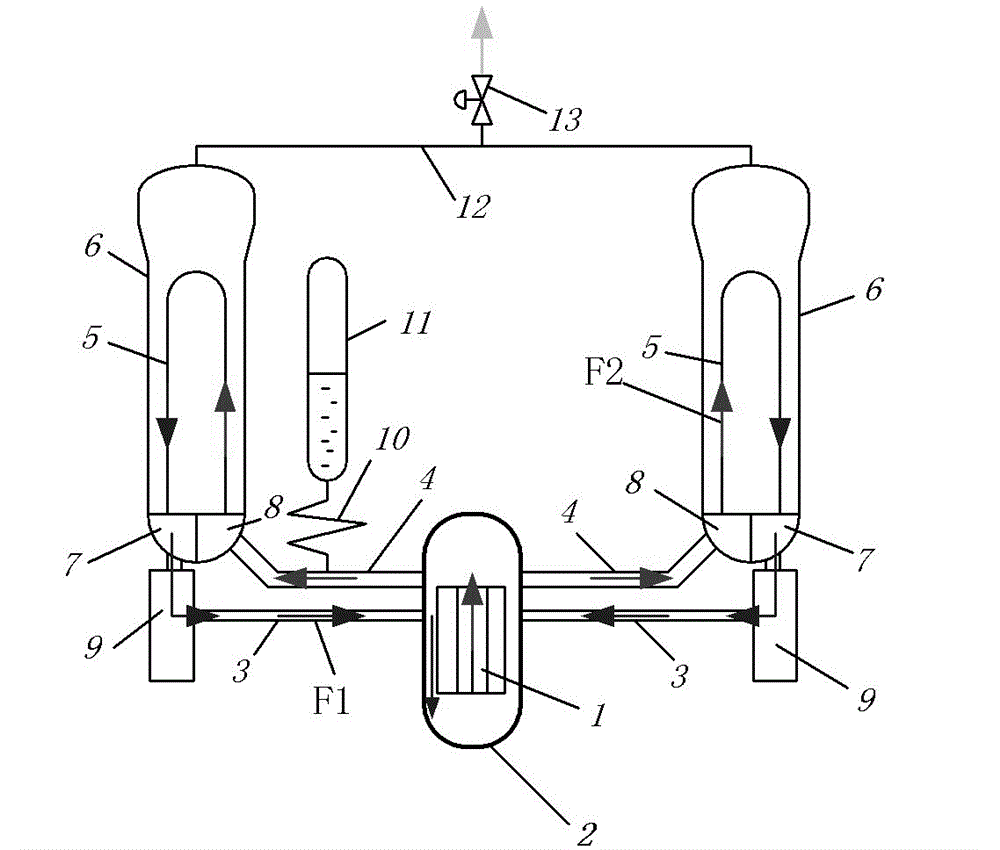

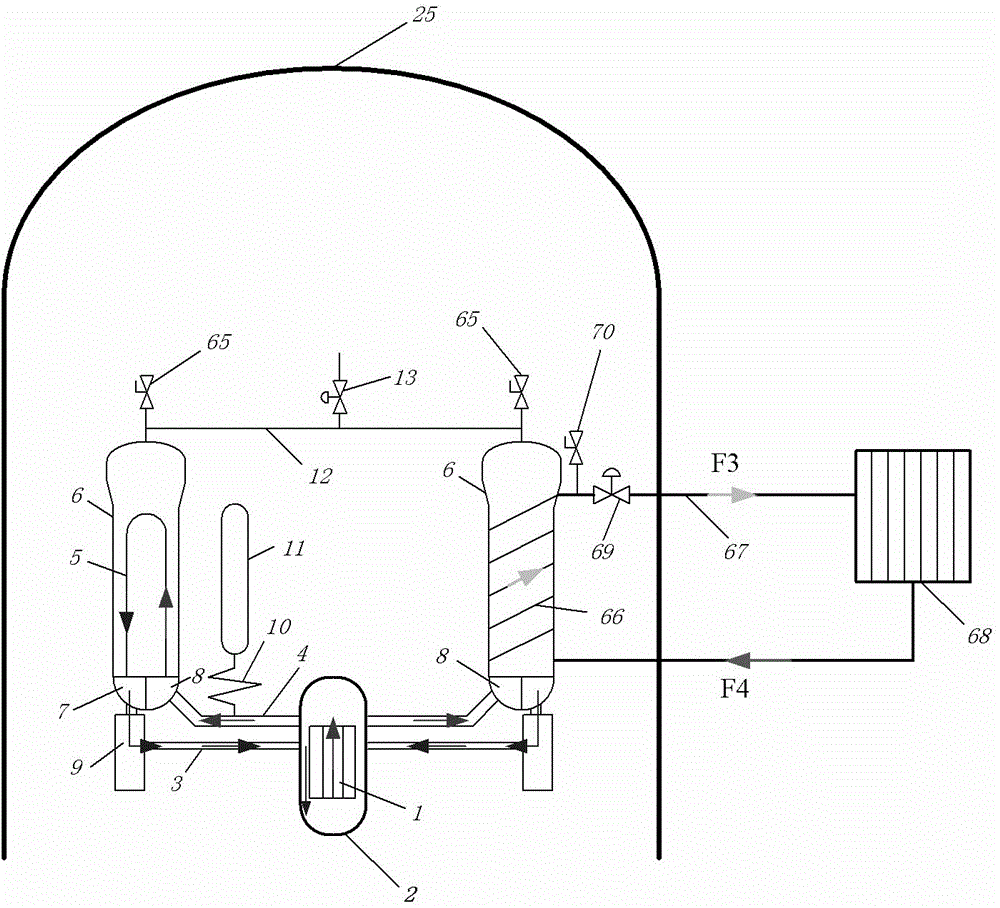

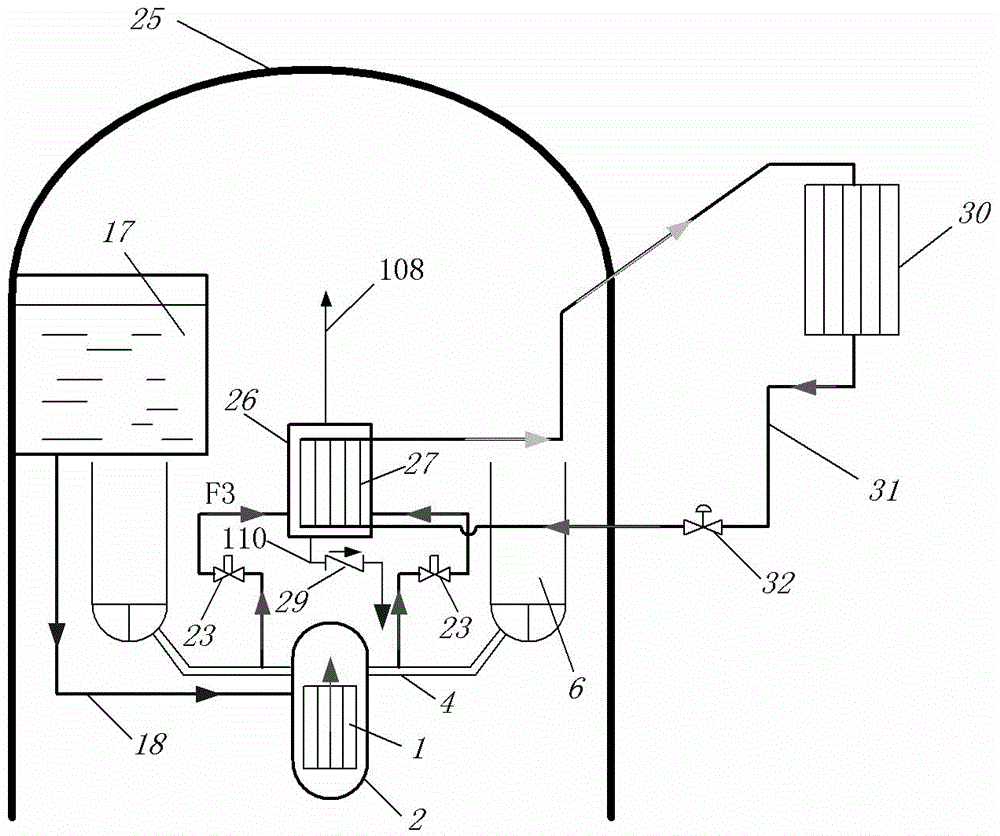

Passive residual heat removal system for nuclear power plant

ActiveCN105810256AConducive to production recoveryRelieve pressureNuclear energy generationCooling arrangementIsolation valveNuclear power

The invention relates to a passive residual heat removal system for a nuclear power plant. The passive residual heat removal system for the nuclear power plant comprises a steam generator shell heat exchanger, a heat exchange loop pipeline, a shell exterior heat exchanger, a pressure maintaining valve, an isolating valve and a heat transferring medium, wherein the heat exchange loop pipeline penetrates through a containment; the steam generator shell heat exchanger is distributed on a steam generator and is communicated with the heat exchange loop pipeline; the shell exterior heat exchanger is arranged outside the containment and is communicated with the heat exchange loop pipeline; the shell exterior heat exchanger is arranged at a high position relative to the position of the steam generator shell heat exchanger; the pressure maintaining valve and the isolating valve are arranged in the containment and are sequentially arranged between the steam generator shell heat exchanger and the shell exterior heat exchanger along a first flow direction of the heat transferring medium in the heat exchange loop pipeline; the passive residual heat removal system for the nuclear power plant is maintained in a relatively low pressure level by virtue of the pressure maintaining valve; and the isolating valve and a shutdown safety signal of a reactor are subjected to interlock opening to be used for continuously taking away heat in the steam generator during an accident.

Owner:STATE NUCLEAR HUAQING BEIJING NUCLEAR POWER TECH R & D CENT +1

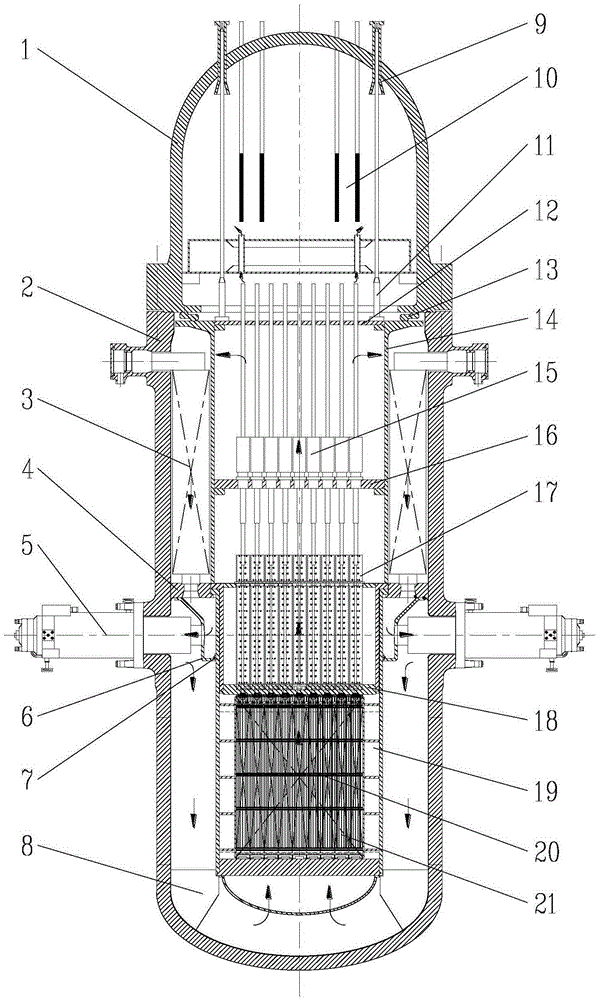

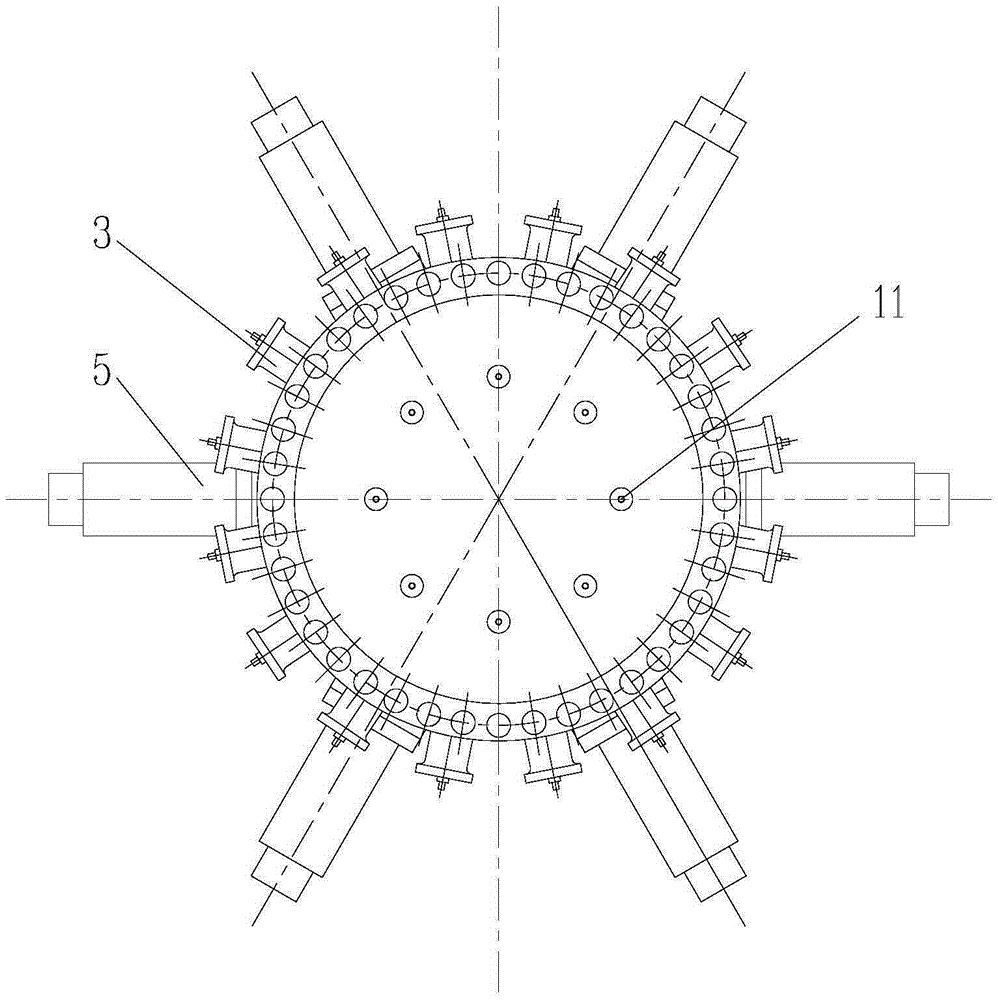

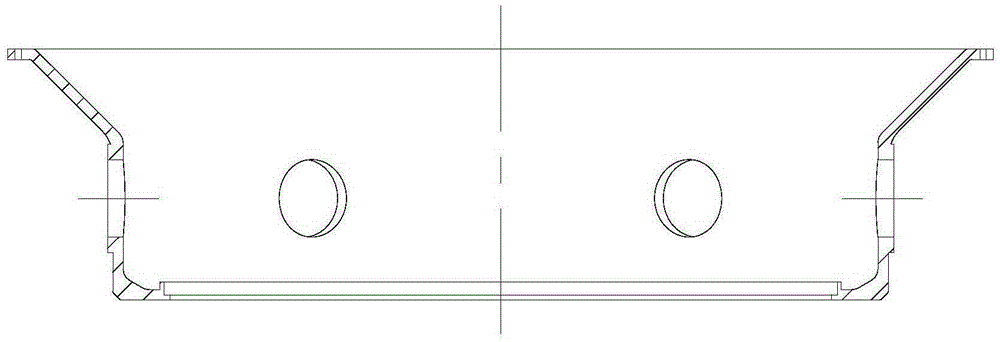

Integrated small reactor

ActiveCN105280257AEliminate large breach accidentsEliminate bouncing accidentsNuclear energy generationContainmentNuclear engineeringPressurized water reactor

The invention belongs to the pressurized water reactor overall structure design technology, and specifically discloses an integrated small reactor. The integrated small reactor comprises a pressure vessel, and a reactor core, a compressing assembly, a control rod assembly, a guide assembly, a control rod driving mechanism and a once-through steam generator which are arranged inside the pressure vessel, and further comprises a main pump directly connected with a cylindrical body of the pressure vessel, wherein the reactor core comprises a reactor core barrel and a fuel assembly; the compressing assembly and the control rod assembly are arranged inside the reactor core barrel; and the pressure vessel is directly connected with the main pump, the main pump is horizontally installed, and an inlet thereof is provided with a flow distribution device. Heating equipment is arranged on a top cover of the pressure vessel, a coolant inside the pressure vessel is subjected to pressure control directly through temperature adjustment, that is, main equipment such as the steam generator, voltage-stabilizing equipment and the control rod driving mechanism are arranged inside the pressure vessel of the reactor at the same time. According to the integrated small reactor, the external loop pipeline is omitted, large break accidents are eliminated, and the structure is compact; and the control rod driving mechanism is arranged internally, the rod ejection accident is eliminated, and the fixation safety is greatly improved.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

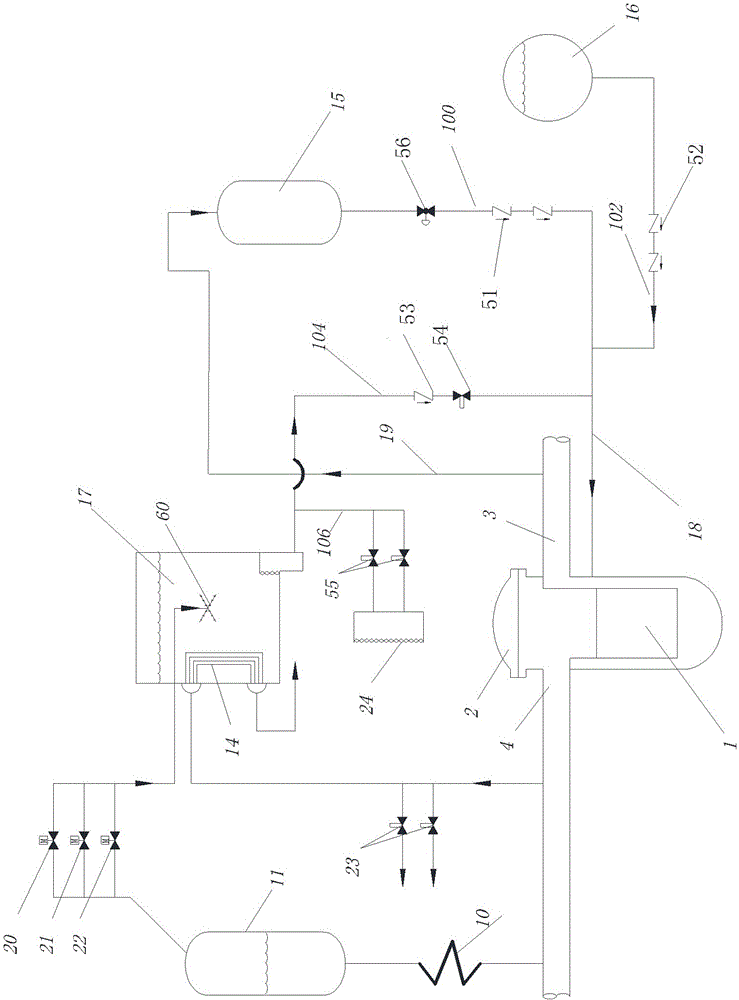

Pressure release condensation heat transfer system for passive nuclear power station

ActiveCN105810257ARelieve pressureTimely inputNuclear energy generationEmergency protection arrangementsPlate heat exchangerWater discharge

The invention provides a pressure release condensation heat transfer system for a passive nuclear power station. The system includes a steam header connected to a main automatic dropping valve and a closed natural circulation loop; the closed natural circulation loop includes a passive steam condensate heat exchanger, a heat transfer loop pipeline, a passive heat exchanger outside the shell and a heat transfer medium. The steam header is in a containment; the top of the steam header is provided with a steam discharge pipeline; the bottom of steam header is provided with a condensate water discharge pipeline; the heat transfer loop pipeline runs through the steam header and the containment; the passive steam condensate heat exchanger is arranged in the steam header and communicated with the heat transfer loop pipeline; the passive heat exchanger outside the shell is arranged outside the containment and communicates with the heat transfer loop pipeline; and the heat transfer medium absorbs heat from the passive steam condensate heat exchanger and transfers the heat to the passive heat exchanger outside the shell through the heat transfer loop pipeline, thereby establishing the closed natural circulation to facilitate continuous removal of core waste heat produced by core residue fission in the case of an accident.

Owner:STATE NUCLEAR HUAQING BEIJING NUCLEAR POWER TECH R & D CENT +1

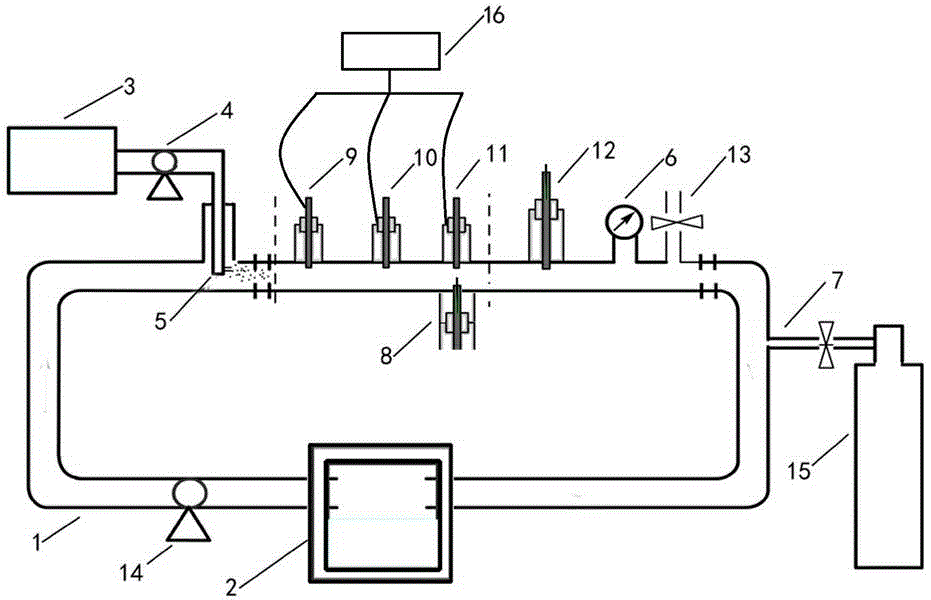

Evaluation testing device of corrosion inhibitor membrane layer of gathering and transportation pipeline

ActiveCN104865179AEffectively evaluate service lifeReduce use costWeather/light/corrosion resistanceElectrochemistryHigh pressure

The invention belongs to the technical field of corrosive prevention in an acid natural gas gathering and transportation pipeline, and particularly relates to a testing device of a corrosion inhibitor membrane layer for resisting hydrogen sulfide and acid corrosion. An evaluation testing device of a corrosion inhibitor membrane layer of a gathering and transportation pipeline, wherein a high pressure kettle and a gas circulating pump are arranged on a lower pipeline of a loop pipeline, and a gas circular pump is located at the left side of the high pressure kettle; several holes are arranged on the upper pipeline of the loop pipeline; an electrical resistance probe, an electrochemistrical probe, a weightless sample, a hygrothermograph, a pressure gauge and a sampler are orderly placed in the holes; corresponding to the lower part of the weightless sample, a hole is arranged on a pipeline on the upper portion of the loop pipeline, and a thickness measuring probe is placed in the hole; an access opening is arranged on the upper pipeline of the loop pipeline, and the access opening is provided with an atomizing nozzle and connected with a corrosion inhibitor storage tank; an outlet of the corrosion inhibitor storage tank is provided with a boosting pump, and the side pipeline of the loop pipeline is connected with a testing gas steel bottle through the gas valve; the weightless sample is connected with an external electrochemistrical work station through a lead.

Owner:中石化石油工程技术服务有限公司 +1

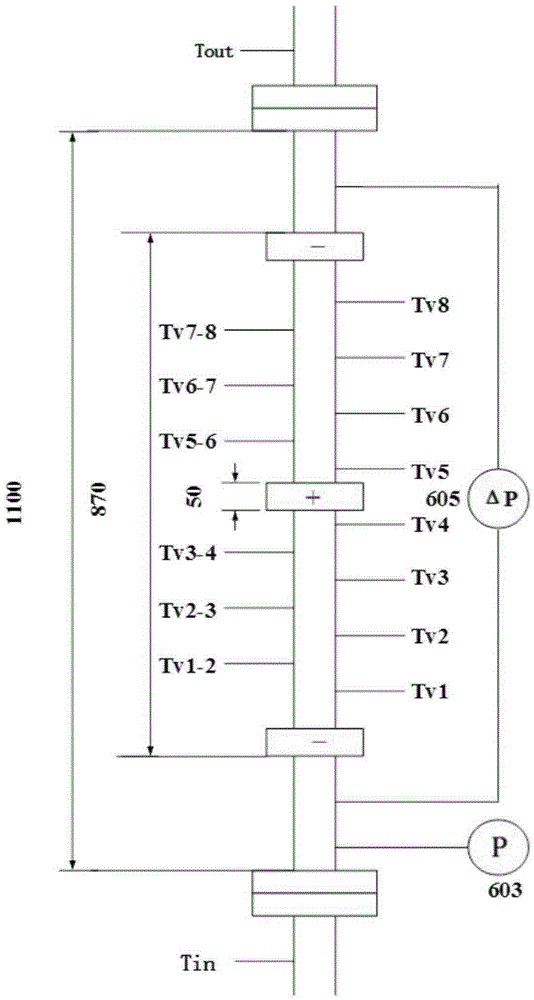

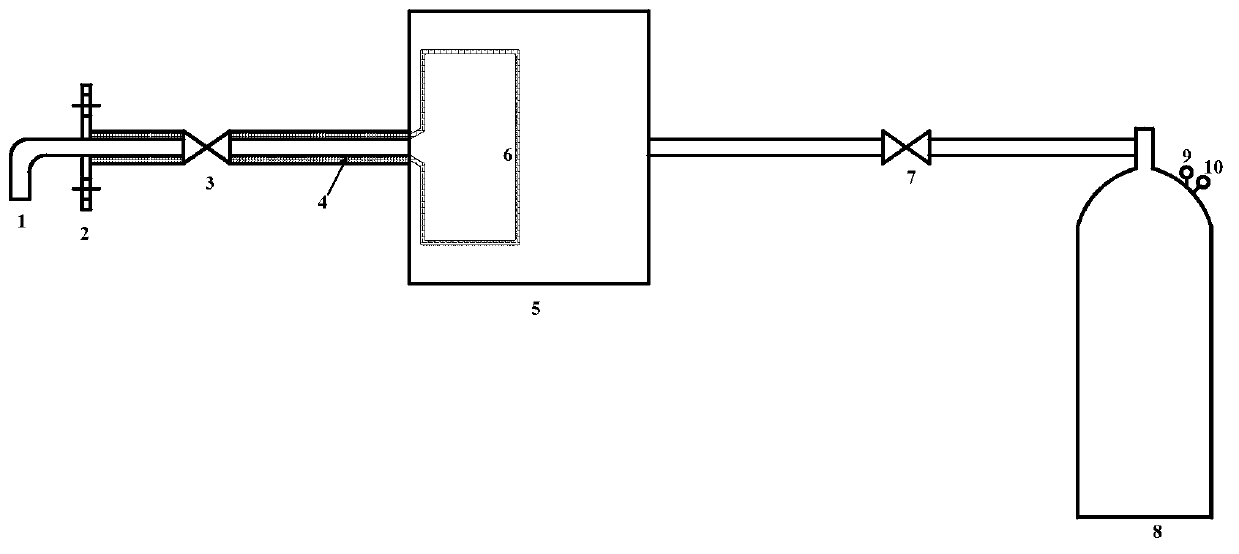

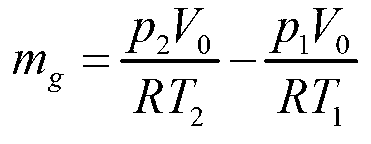

Device and method for measuring concentration of graphite dust in primary loop pipeline of high temperature gas cooled reactor

ActiveCN103278434ARealize measurementGuaranteed accuracyWithdrawing sample devicesParticle suspension analysisDifferential pressureProcess engineering

The invention provides a device and a method for measuring the concentration of graphite dust in a primary loop pipeline of a high temperature gas cooled reactor. The device comprises a sampling tube, a dust collecting chamber and a gas storage tank, wherein a gas inlet of the sampling tube is formed in the primary loop pipeline, a gas outlet of the sampling tube is connected with the dust collecting chamber, and the dust collecting chamber is connected with the gas storage tank through a pipeline. The whole device overcomes the thermal gradient sedimentation, does not use a differential pressure sensor or a flow meter, and is simple in structure, stable in performance and convenient to maintain. In the collecting process, high pressure gas flow containing the graphite dust in the high temperature gas cooled reactor can flow through the sampling tube and the dust collecting chamber, wherein the graphite dust can be intercepted by a dust collecting net in the dust collecting chamber, and the high pressure gas flow can be stored in the gas storage tank. By measuring the mass of the graphite dust intercepted in the dust collecting chamber and the amount of the gas collected in the gas storage tank, the concentration of the graphite dust in the primary loop pipeline of the high temperature gas cooled reactor can be calculated.

Owner:TSINGHUA UNIV

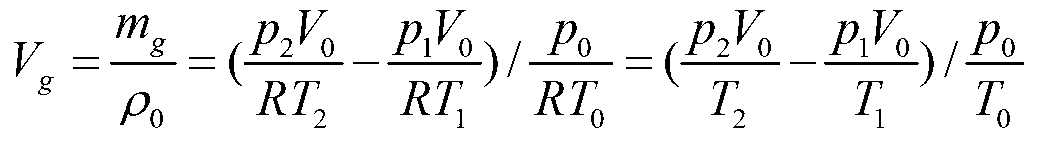

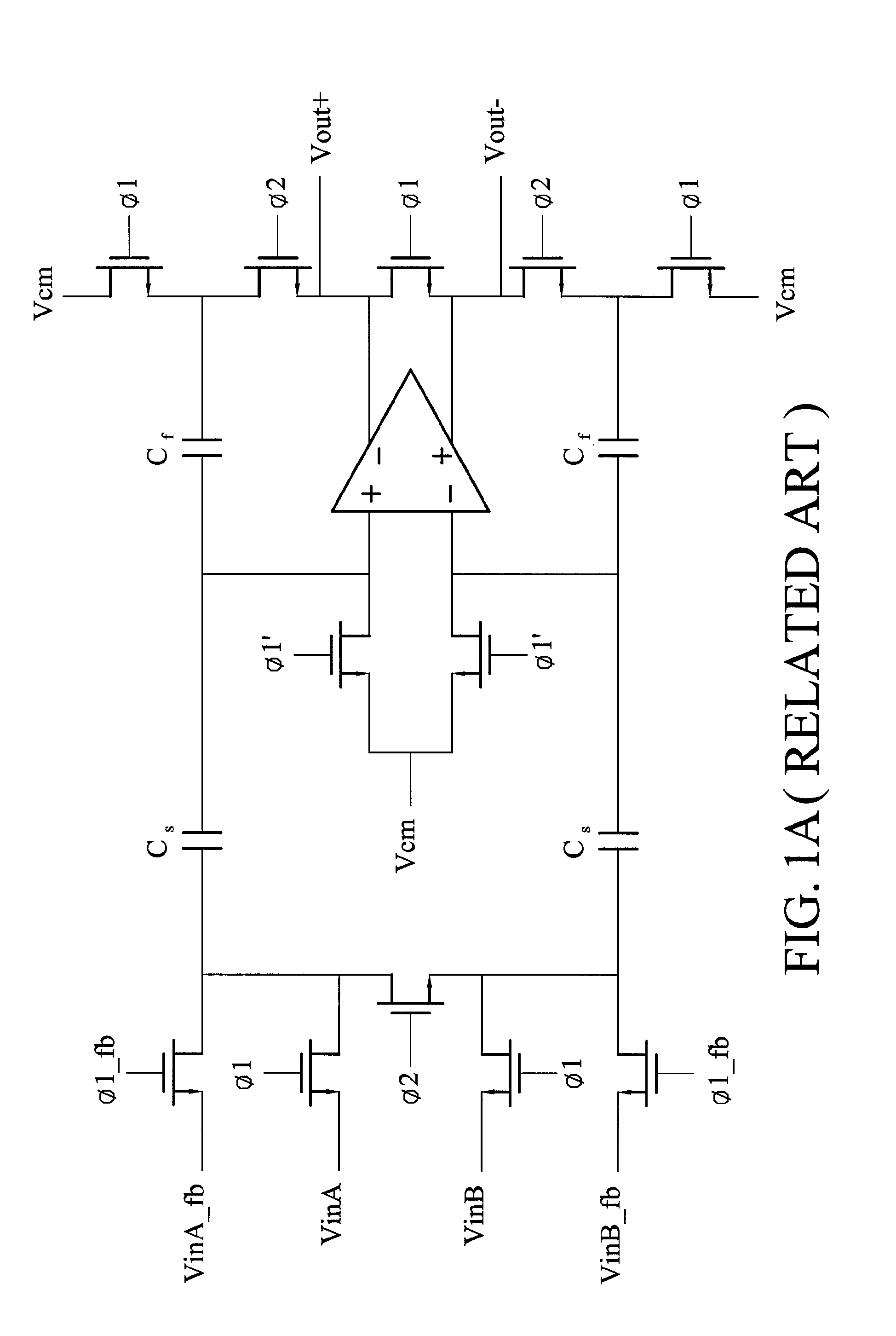

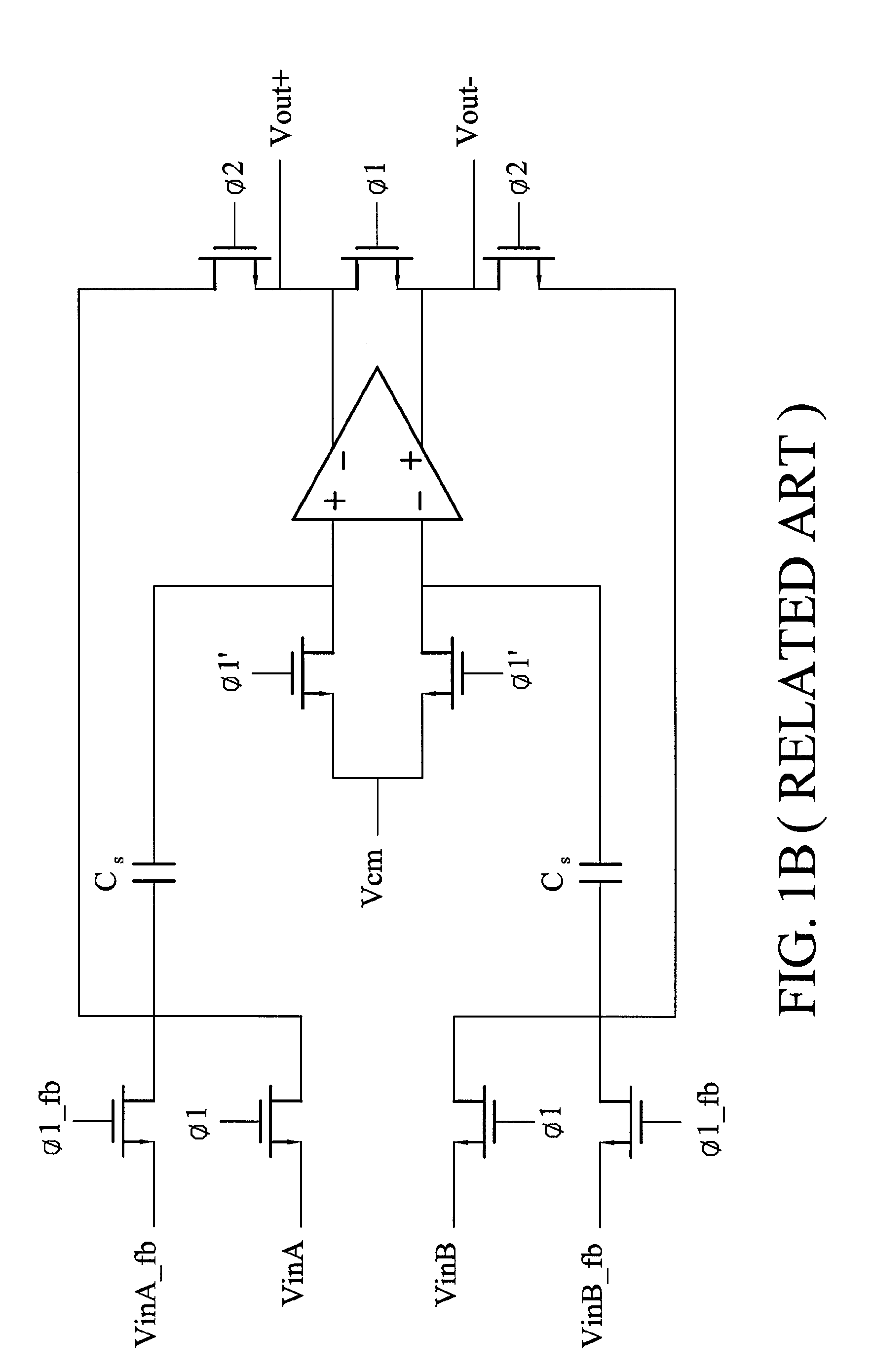

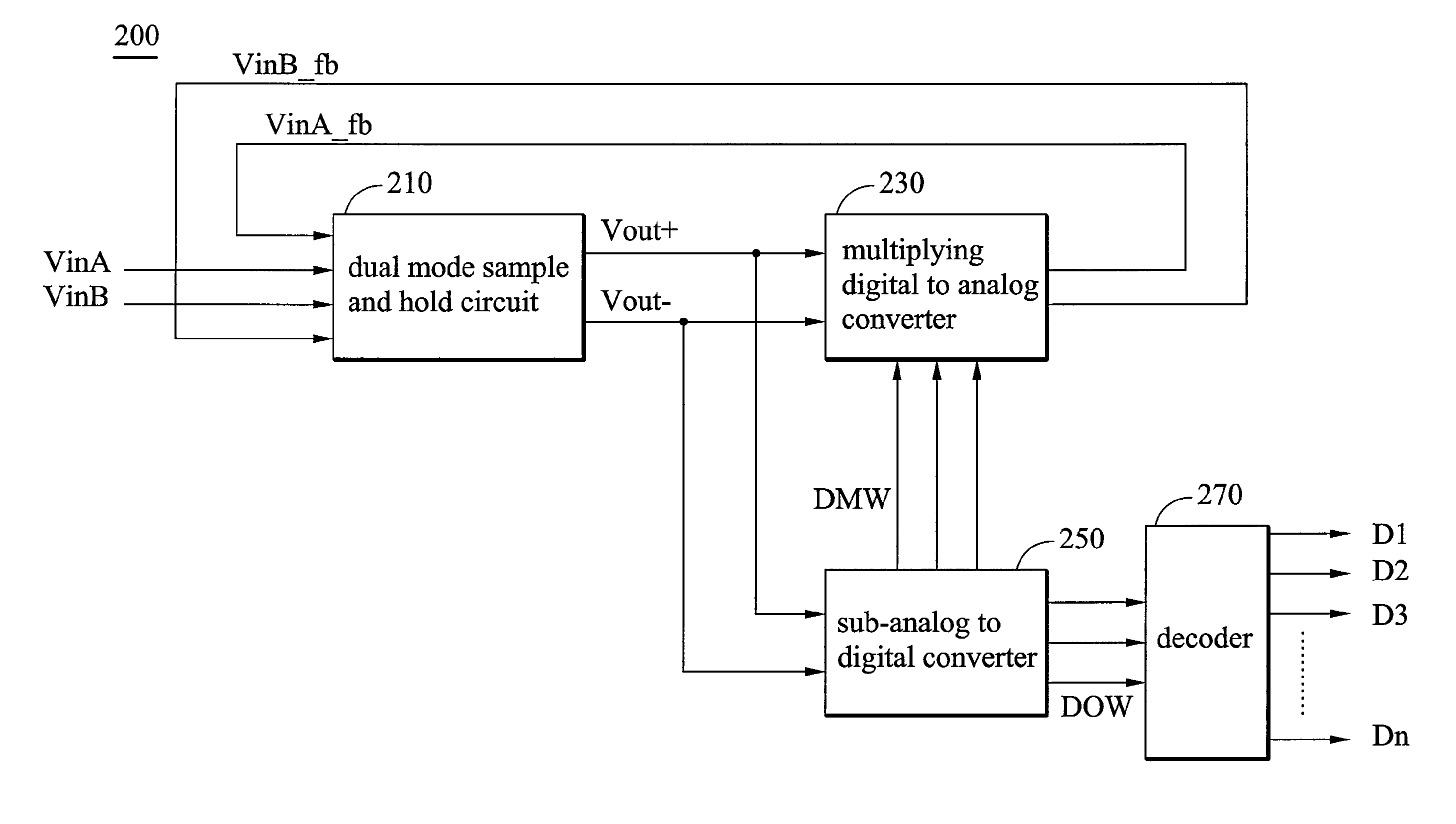

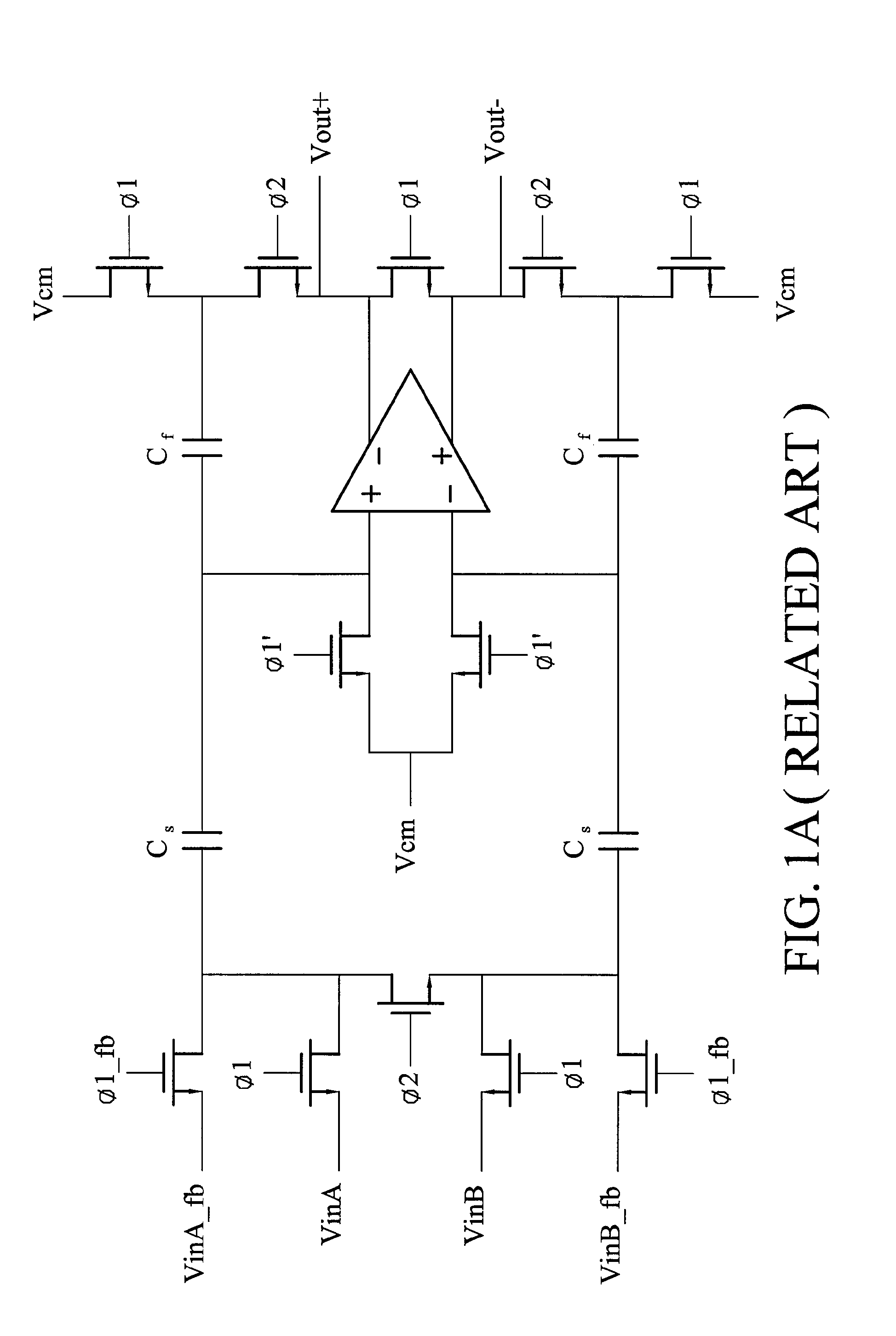

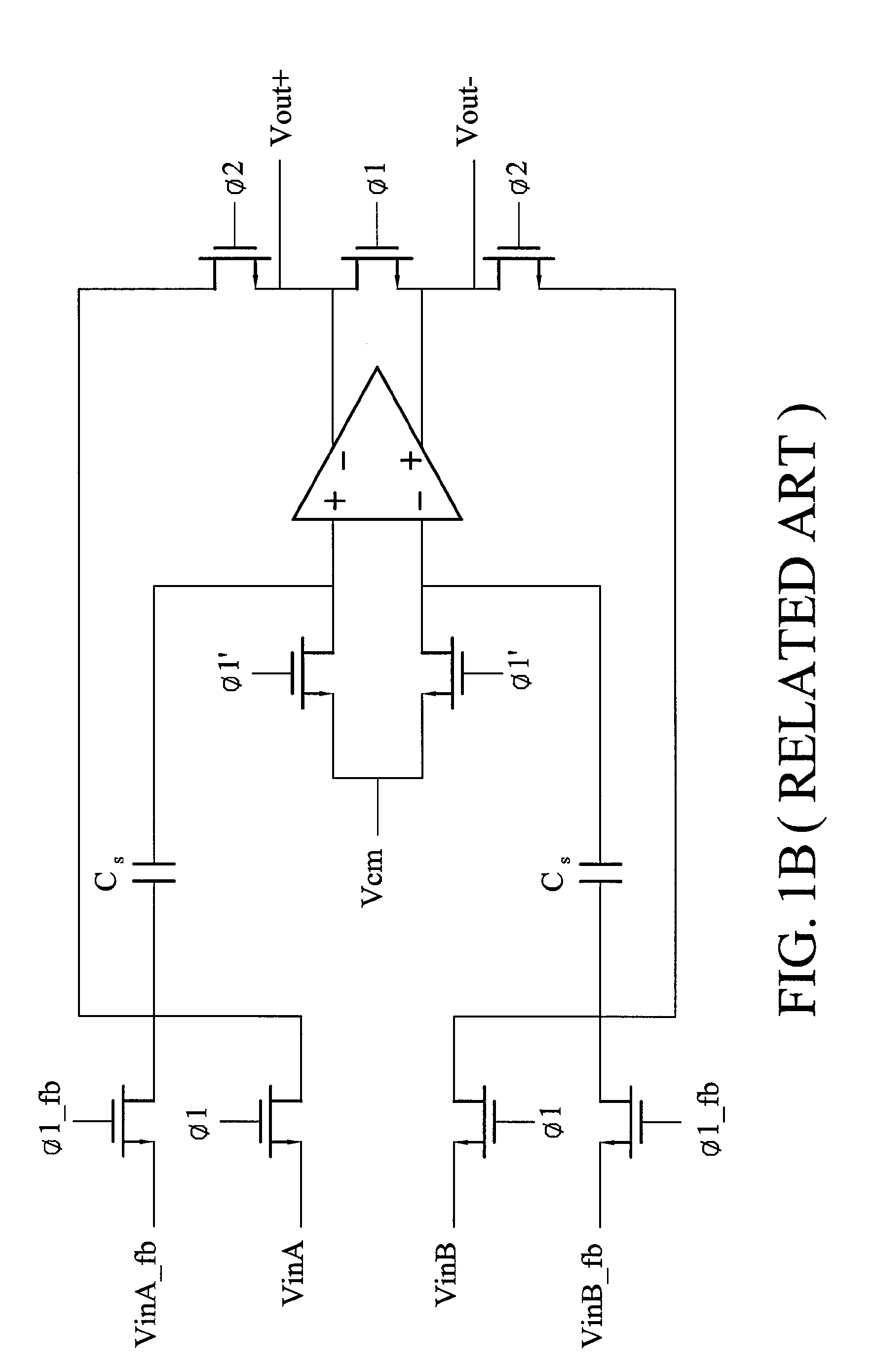

Dual mode sample and hold circuit and cyclic pipeline analog to digital converter using the same

ActiveUS7333039B2Reduce errorsIncrease rangeElectric signal transmission systemsAnalogue-digital convertersDigital down converterDual mode

A cyclic pipeline analog to digital converter includes a dual mode sample and hold circuit, a multiplying digital to analog converter (MDAC), a sub-analog to digital converter (sub-ADC) and a decoder. The dual mode sample and hold circuit has a charge-redistribution mode and a flip-around mode. The dual mode sample and hold circuit receives first and second input voltages and first and second feedback voltages and generates a differential output signal pair. The MDAC receives the differential output signal pair and a digital multiplying word and generates the first and second feedback voltages. The sub-ADC receives the differential output signal pair and generates the digital multiplying word and a digital output word. The decoder converts the digital output word to a digital output corresponding to the first and second input voltages.

Owner:VIA TECH INC

Surface water and underground water undercurrent exchange self-loop test device and usage method thereof

A surface water and underground water undercurrent exchange self-loop test device disclosed by the invention comprises a water tank. The water tank comprises an excess-of-water layer, a deposition layer and a sand filtering layer. An upstream water tank and a downstream water tank are respectively fixed at two ends of the water tank, an energy dissipation hole plate and a tail-gate device are respectively arranged at the communication position of the upstream water tank and the excess-of-water layer and the downstream water tank and the excess-of-water layer, a self-loop pipeline is communicated between the bottoms of the upstream water tank and the downstream water tank, the lower portion of the water tank is fixedly communicated with a plurality of underground water tanks, the underground water tanks, the upstream water tank and the downstream water tank re internally provided with solute measurement devices, the bottoms of the underground water tanks are communicated to the upstream water tank through an underground water pipeline, and the underground water pipeline is provided with a peristaltic pump. The usage method comprises: adding clear water into the deposition layer until saturation; adding the solute to a surface water unit; supplying water to a target water level to the surface water unit; opening a surface water self-loop system; opening the peristaltic pump until the solute concentration pf the surface water unit and the underground water unit is constant; and calculating the undercurrent exchange capacity of the water tank.

Owner:XIAN UNIV OF TECH

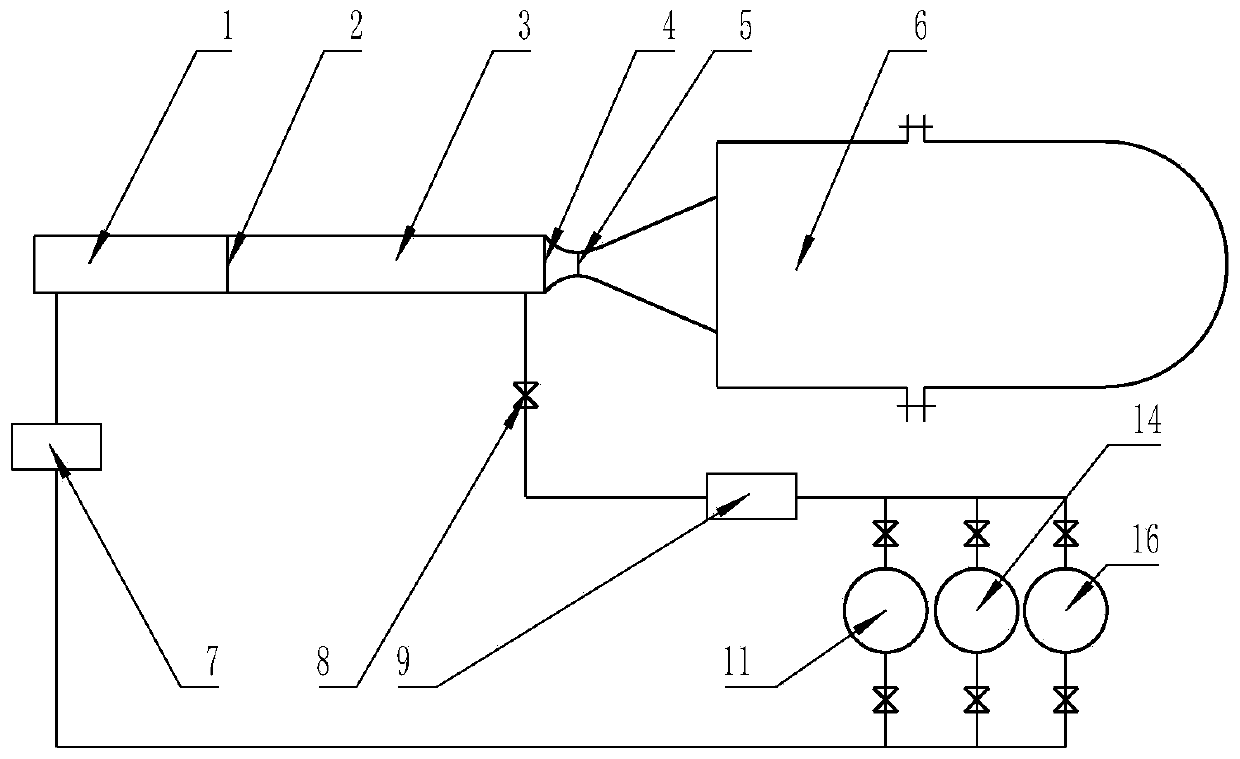

Device for simulating graphite dust emission during break accident of high-temperature reactor and discharge testing method

ActiveCN103308275AMeet static pressure injection requirementsHydrodynamic testingCollection systemProcess engineering

The invention provides a device for simulating graphite dust emission during a break accident of a high-temperature reactor and a discharge testing method. The device comprises a pressure injection system, a main loop pipeline system, a spray pipe discharge system and a vacuum can collection system. Based on analysis a similar principle, external air enters the main loop pipeline system through the pressure injection system to achieve a design rated value, and fine graphite dust is added into a pipeline by a dust addition system to form uniform gas dust two-phase flow under the driving of a circulating fan. By designing a spray pipe discharge pipe system vertically connected with a main loop pipeline, graphite dust is sprayed into a vacuum tank through a transonic spray pipe under the action of static pressure of main loop gas, the graphite dust in the main loop is discharged into the vacuum tank along with the air flow, and the graphite dust which is discharged into the vacuum tank is collected, so that the emission of the graphite dust of the high-temperature gas cooled reactor under accident conditions can be predicted.

Owner:TSINGHUA UNIV

Wind tunnel helium reuse device

The invention discloses a wind tunnel helium reuse device. The device comprises a high pressure section, a membrane I, a low pressure section, a membrane II, a throat valve and a test section, which are sequentially connected along the gas flow direction to form a wind tunnel; the device further comprises a gas flow loop pipeline connected between the high pressure section and a gas storage tankfor flowing from the high pressure section to the gas storage tank and flowing from the gas storage tank to the high pressure section, and an exhaust valve, a low pressure compressor, three groups ofgas storage tanks connected in parallel and a high pressure compressor are sequentially installed on the gas flow loop pipeline in sequence. Helium with different degrees of purity is stored in the gas storage tanks respectively, and the gas storage tank with the similar purity is selected according to the purity of the helium required for the test. The wind tunnel helium reuse device disclosed bythe invention has the advantages of simplicity, high efficiency and low use cost.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

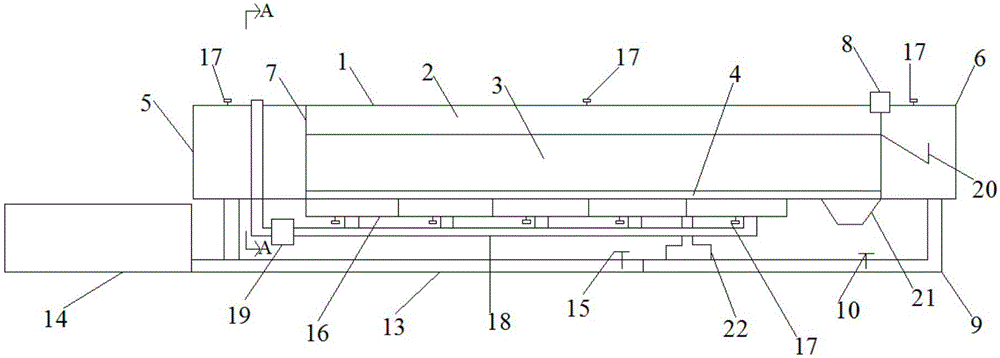

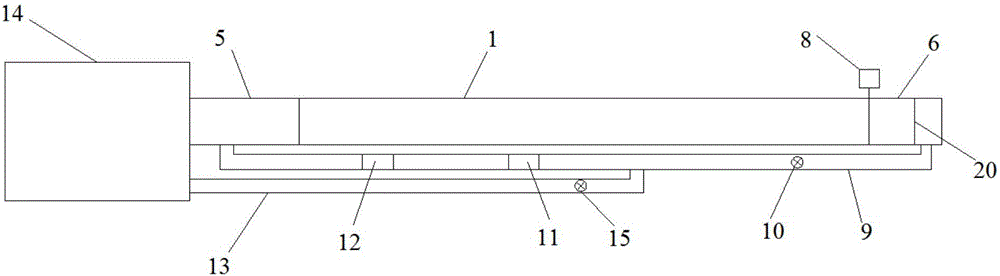

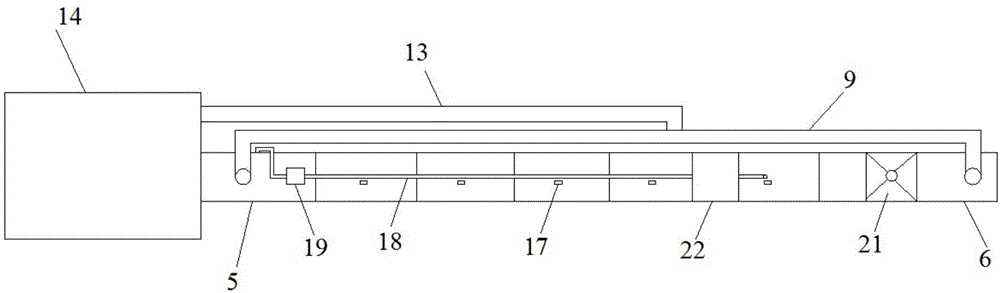

Super-high temperature liquid medium thermal convection experimental loop

InactiveCN104198521AGuaranteed distribution in specific temperature zonesMeet the needs of long-term corrosion experimentsMaterial thermal analysisMelting tankTemperature control

The invention discloses a super-high temperature liquid medium thermal convection experimental loop which comprises a linear track type box body heating furnace and a loop pipeline, wherein the linear track type box body heating furnace comprises a furnace body, a heater, a linear guide rail and a base frame; the loop pipeline comprises a melting tank, an extraction opening, a loop main body, an online sampling system, an air cooling dual-layer sleeve and an emptying pipe. Due to an optimized design of the linear track type box body heating furnace, specific temperature zone distribution required by thermal convection of the experimental loop is ensured; meanwhile, due to material selection and a structure of the loop pipeline, the requirement of performing a long-term corrosion experiment of a reactor candidate material in an super-high temperature thermal convection medium can be met. The super-high temperature liquid medium thermal convection experimental loop has the characteristics that the loop pipeline is simply and conveniently replaced, online sampling and installing can be realized, temperature controlling precision is high and the like, can be used for developing compatibility experiment research of the material in a flow medium, and is especially suitable for screening and developing the reactor high-temperature-corrosion-resisting material.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

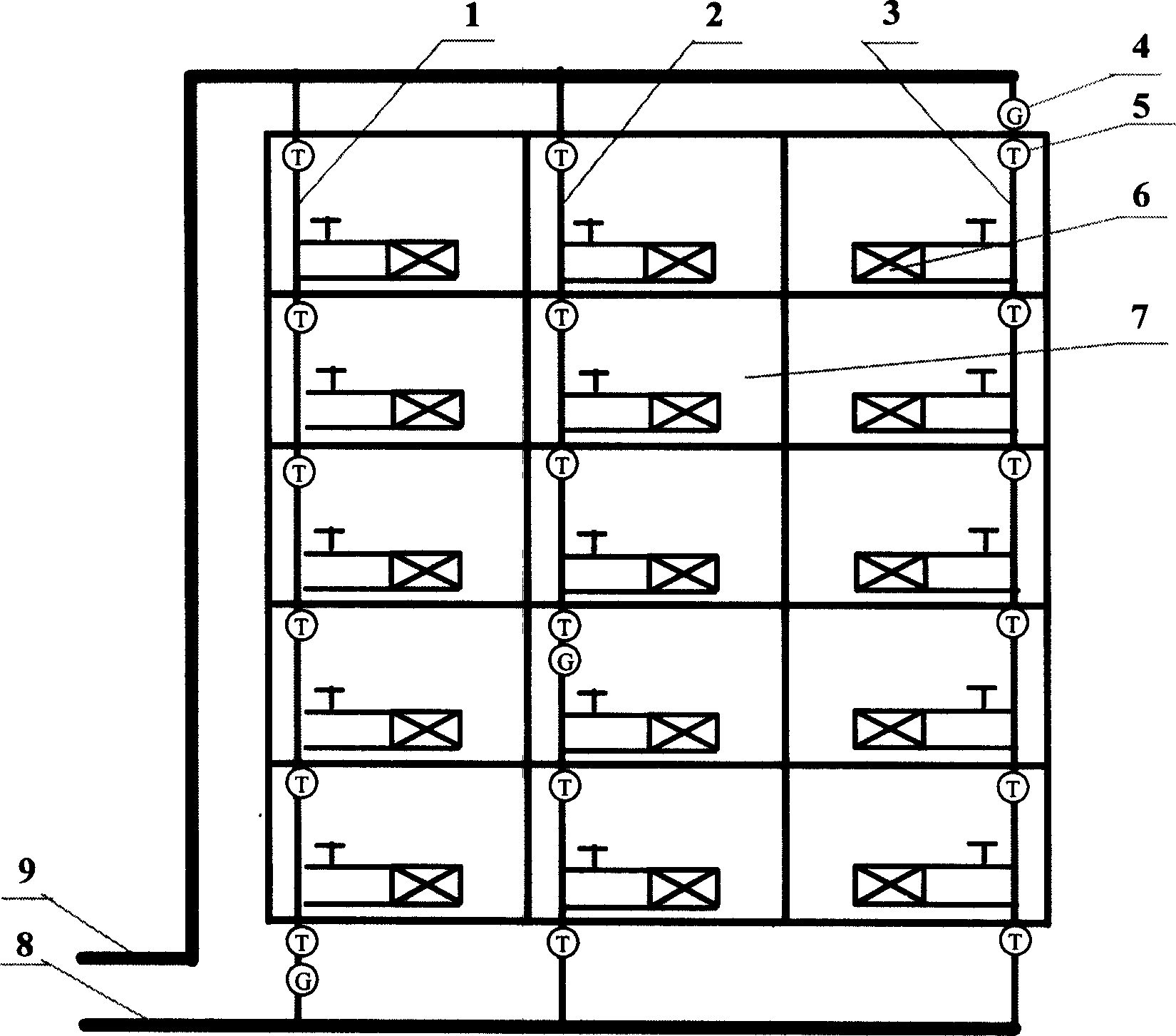

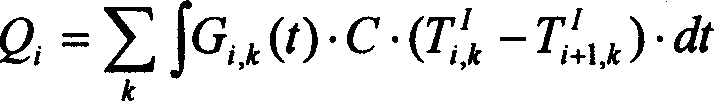

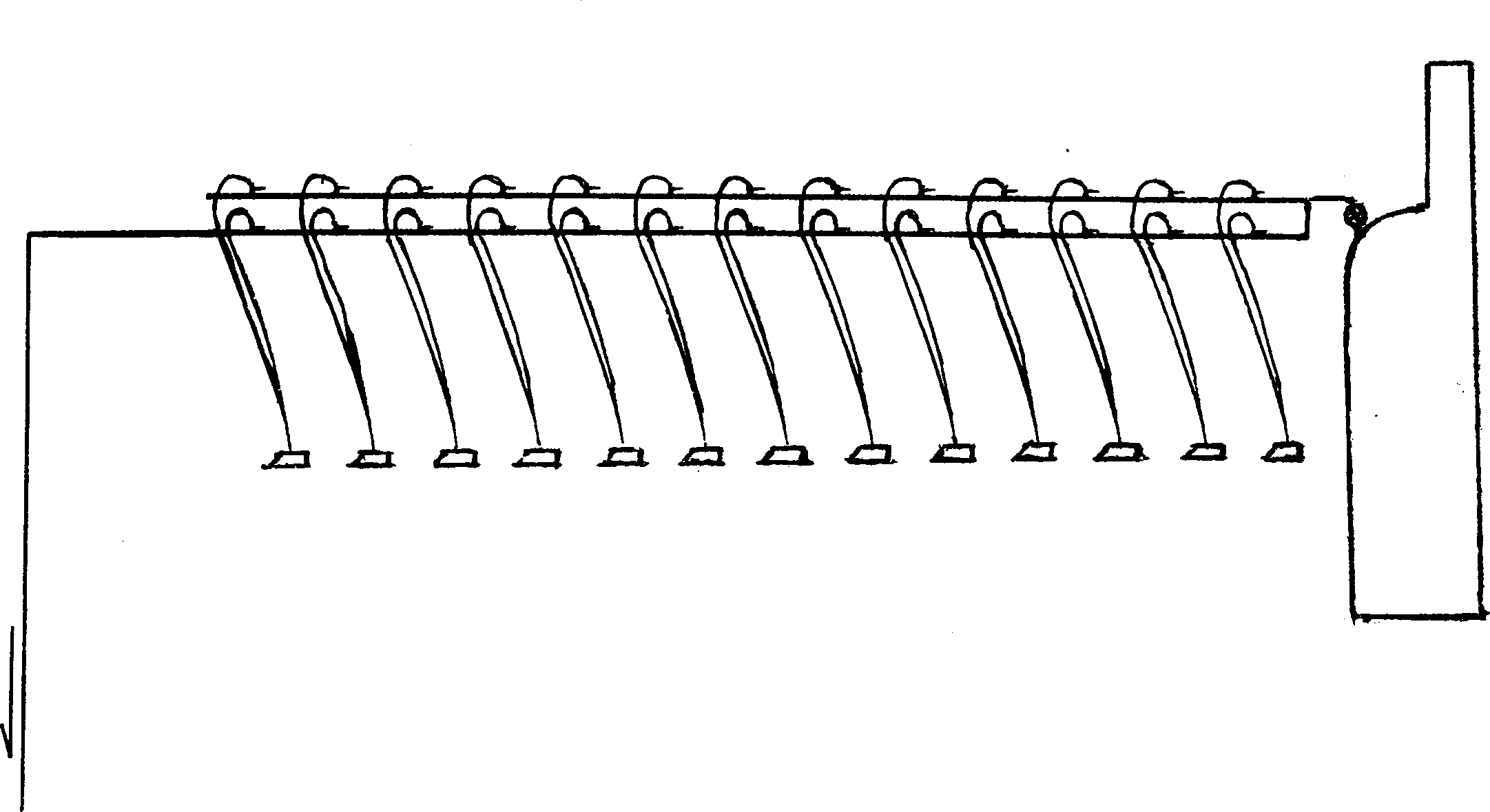

Heat metering method for open-ring central heating system

The present invention relates to a method for measuring heat quantity provided for user in an open-loop heating system. Said method is characterized by that on the water-supplying riser pipe of open-loop pipeline heating structure a flow measuring point is set, in the front end and outlet of every radiator of said water-supplying riser pipe a temperature measuring point is set respectively, so that they can be formed into a series-connected temperature flow combined arrangement mode; the measured parameters of flow measuring point are identical to three measured parameters required for heating quantity calculation mode of calorimeter, said invention utilizes the summation of heating quantities of all the water-supplying riser pipes in the user so as to obtain the heat amount provided for user.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Steam-vapour three-purpose pipe distributing method of iron

InactiveCN1793480ARealize the purpose of FAW three-purposeAir dryingHand ironTextiles and paperWater filterSteam trap

The invention relates to an iron, steam and vapor three-use pipe arrangement method. One unit steam scalding iron is divided into A, B, C three areas. The A area main pipeline is connected with boiler by steam master valve. Its tail is set steam water filter. And its turning part is set steam trap. And it is connected with looped pipeline and their middle is set steam self control compensator. The tail of the looped pipeline is set steam separator. The tail of B main pipeline is connected with high pressure entrance of pressure self regulating tail gas controller. And its turning part is set steam trap. It is connected with looped pipeline and their middle is set steam self-control compensator. The tail of the looped pipeline is connected with low pressure entrance of the controller. The C main pipeline is connected with tail gas reuse port of the controller. The C looped pipeline, pressure self regulating tail gas controller, steam separator, discharge opening of steam filter are connected with return pipe. Thus it can economize energy resources.

Owner:陈光焕

Double-faced automatic upper disk and lower disk weaving mechanism of underwear machine and pneumatic color spacing mechanism arm device

The invention discloses a double-faced automatic upper disk and lower disk weaving mechanism of an underwear machine and a pneumatic color spacing mechanism arm device. The double-faced automatic upper disk and lower disk weaving mechanism of the underwear machine and the pneumatic color spacing mechanism arm device comprise a needle disk base, a cutter disk base, a big-disk gear, a needle selector, a lower-section needle cylinder, a saddle base ring, an upper-section needle cylinder, a mechanical arm body, a yarn outlet mechanism pneumatic loop module and a yarn cutting mechanism pneumatic loop module. A needle disk is connected to the needle disk base. A cutter disk is connected to the cutter disk base. An air cylinder needle selecting device is connected to the cutter disk. The lower-section needle cylinder is connected to the big-disk gear. The needle selector is connected to the big-disk gear. The upper-section needle cylinder is connected to the lower-section needle cylinder. A reset triangle is connected to the saddle base ring. An automatic needle moving triangular mechanism is connected to the saddle base ring. An air inlet is formed in the mechanical arm body. The yarn outlet mechanism pneumatic loop module is connected to the upper end of the mechanical arm body. A yarn cutting mechanism pneumatic loop pipeline and a yarn cutting mechanism pipeline are communicated with the air inlet. The double-faced automatic upper disk and lower disk weaving mechanism of the underwear machine and the pneumatic color spacing mechanism arm device have the advantages of being simple in structure, convenient to operate and practical.

Owner:福建佰源智能装备股份有限公司

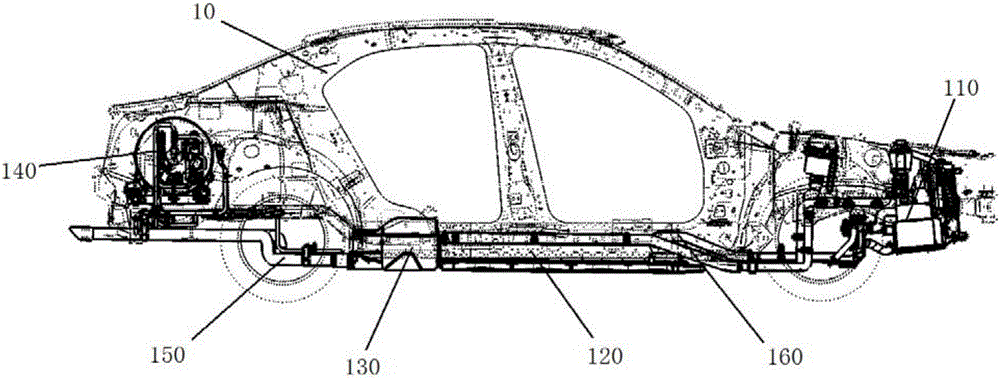

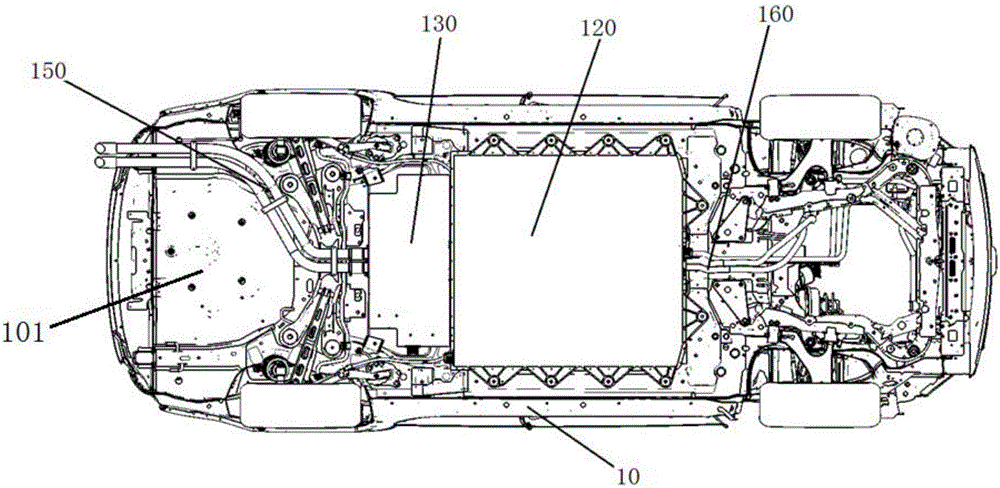

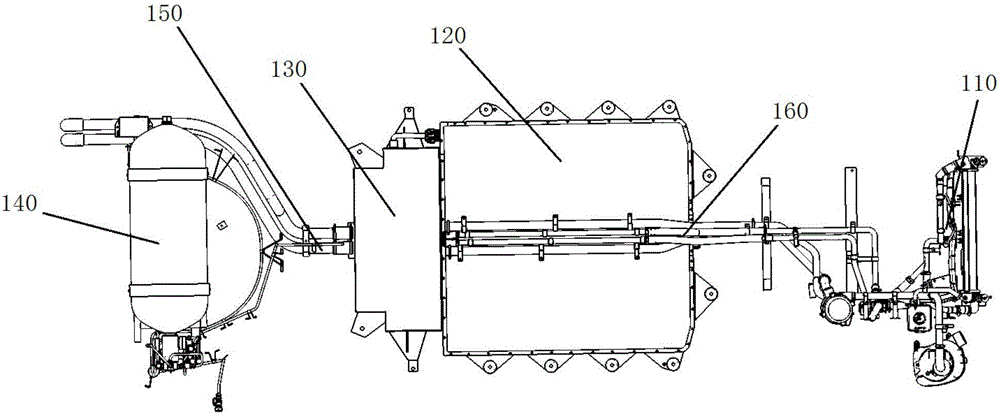

Fuel cell electric vehicle

InactiveCN106828067ASolve the problem of high development cost consumptionElectric propulsion mountingPropulsion coolingFuel cellsHydrogen

The invention provides a fuel cell electric vehicle. The fuel cell electric vehicle includes: a fuel cell system arranged in a vehicle body; the fuel cell system includes: an air intake cooling system, a power Battery, fuel stack integrated module and hydrogen bottle; wherein, the hydrogen bottle is set in the trunk of the body; the fuel stack integrated module is set under the rear seat of the body, and the fuel stack integrated module is connected to an exhaust pipe; The power battery is set under the floor in the middle of the body, and the power battery is connected to the fuel stack integrated module; the air intake cooling system is set in the engine room in front of the body, and the air intake cooling system is connected to the fuel stack integrated module through the return pipeline connect. The arrangement of the fuel cell system satisfies the requirement of developing a fuel cell vehicle on the basis of an existing vehicle body, saves development costs, and shortens a development cycle.

Owner:BEIJING ELECTRIC VEHICLE

Dual mode sample and hold circuit and cyclic pipeline analog to digital converter using the same

ActiveUS20070090984A1Increase input common mode rangeReduce the impactElectric signal transmission systemsAnalogue-digital convertersDual modeA d converter

A cyclic pipeline analog to digital converter includes a dual mode sample and hold circuit, a multiplying digital to analog converter (MDAC), a sub-analog to digital converter (sub-ADC) and a decoder. The dual mode sample and hold circuit has a charge-redistribution mode and a flip-around mode. The dual mode sample and hold circuit receives first and second input voltages and first and second feedback voltages and generates a differential output signal pair. The MDAC receives the differential output signal pair and a digital multiplying word and generates the first and second feedback voltages. The sub-ADC receives the differential output signal pair and generates the digital multiplying word and a digital output word. The decoder converts the digital output word to a digital output corresponding to the first and second input voltages.

Owner:VIA TECH INC

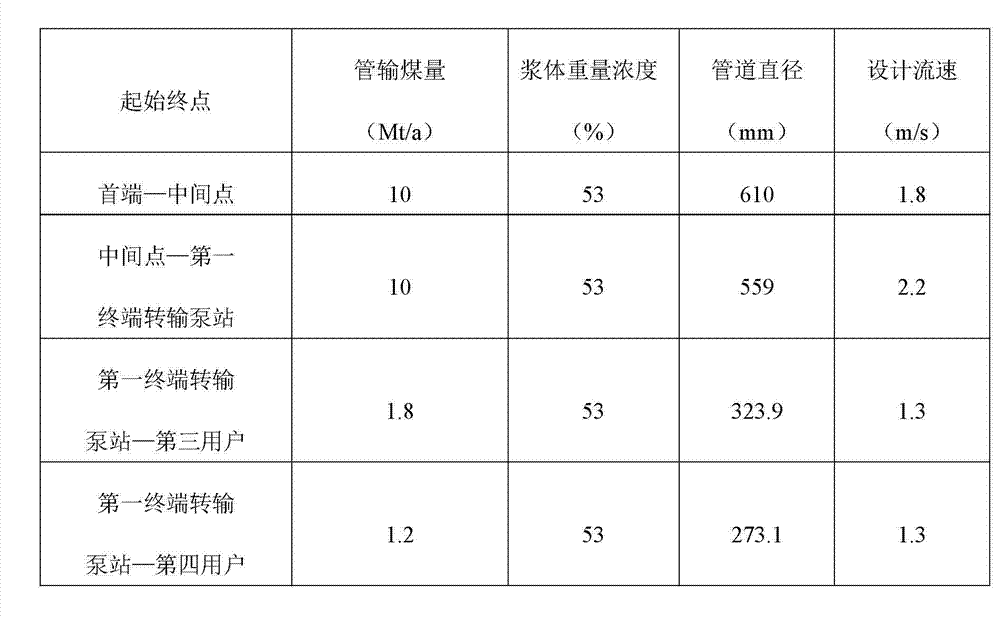

Large-volume long-distance airtight relay pipeline coal handling system and method

InactiveCN102862822AReduce transportation pressureReduce wearBulk conveyorsHandling systemHeavy load

The invention discloses a large-volume long-distance airtight relay pipeline coal handling system and method. The delivering process includes the steps that coal slurry is fed into a loop pipeline through a slurry feeding pump and then fed into a main delivery pump and a pipeline of a first-level pump station after detected qualified, and main pumps are used for adding pressure to deliver the qualified coal slurry air tightly to a second relay pump station and the pipeline and finally to a user terminal. A clean water pool and a waste slurry pool are arranged in each pump station which is composed of a relay pump station and a transfer pump station; a pressure instrument and an overpressure tapping valve are arranged on an inlet manifold and an outlet manifold of each pump station and each pump; buffer gas tanks are arranged at the inlet and outlet of the main pumps; and the main pumps in each pump station are in a parallel connection, and an electron coupling mode is adopted to control the start and stop of the pumps. According to the system and the method, the structure is reasonable, the automation degree is high, the utilization and operation are simple and convenient, transportation pressure of trains and automobiles is reduced, abrasion of heavy-load automobiles to roads is reduced, and traffic accidents are reduced.

Owner:WUHAN DESIGN & RES INST OF CHINA COALTECH & ENG GROUP

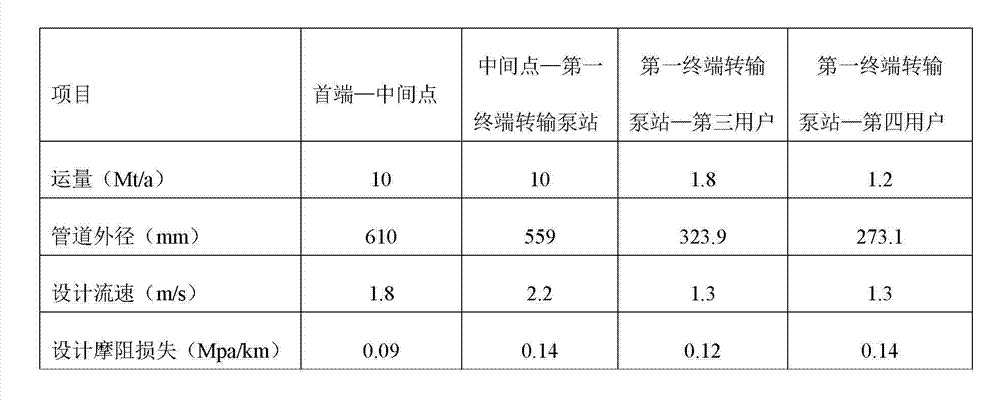

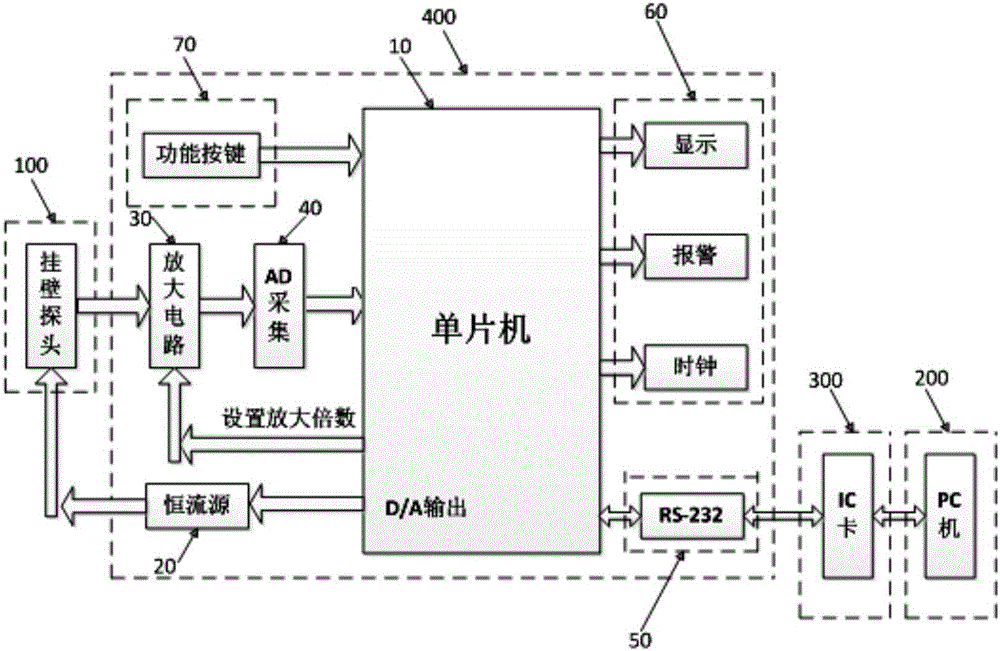

Oil-line corrosion and gas monitoring system of transformer

InactiveCN105988015ARealize online analysisImprove applicabilityWeather/light/corrosion resistanceComponent separationElectrical resistance and conductanceGas phase

The invention relates to an oil-line corrosion and gas monitoring system of a transformer. The oil-circuit corrosion and gas monitoring system comprises a wall-hanging probe, a PC, an IC card chip and a corrosion measuring and chromatographic analysis system, wherein the wall-hanging probe comprises a resistance needle and a gas sensor, the resistance needle comprises an exposure test piece for monitoring corrosion and a closed hanging piece used as reference, resistance and gas signals acquired by the wall-hanging probe attached in an oil pipeline of the transformer are sent to the corrosion measuring and chromatographic analysis system to be under the chromatographic analysis and to calculate and display the corrosion speed, the corrosion measuring and chromatographic analysis system is communicated with and transmits data to a principal computer through an IC card, and the principal computer saves and inputs the data by using the IC card. By adopting the oil-line corrosion and gas monitoring system, the oil-loop pipeline corrosion and gas phase chromatographic online analysis is realized. The oil-line corrosion and gas monitoring system has the characteristics of simplicity, sensitivity and high practicability and is mainly applied to the field of monitoring oil loops of 500KV transformers and electric reactors.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Space debris prevention type heat radiator

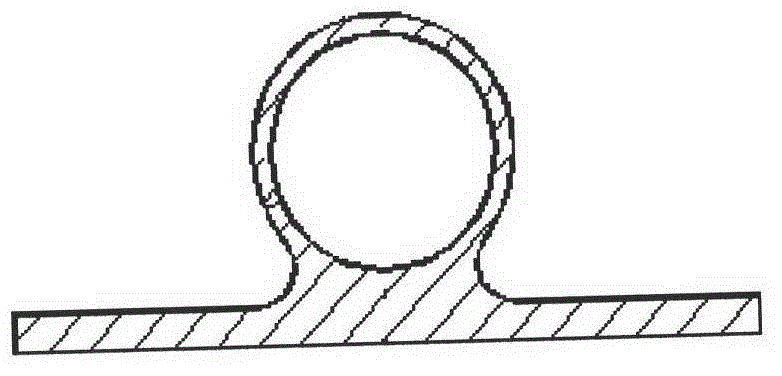

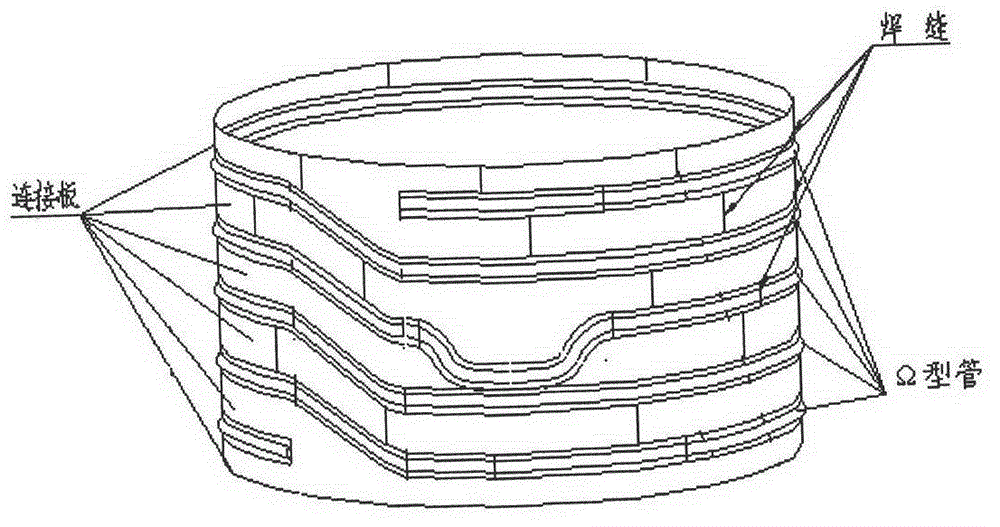

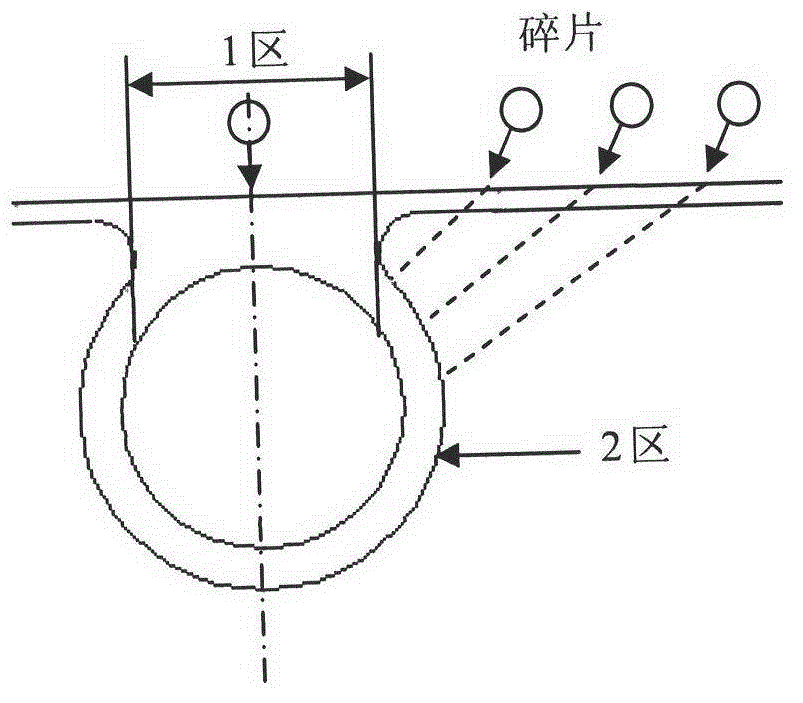

ActiveCN102941926ADoes not affect workReduce the chance of hittingCosmonautic vehiclesCosmonautic partsEngineeringPrevention types

The invention relates to a space debris prevention type heat radiator, which is a cylindrical structure formed by a plurality of connecting plates in a surrounding way. Heat pipes which are arranged in parallel are arranged on one side of the connecting plates. A fluid pipeline is arranged on the heat pipes in the shape of a continuous square wave. One part of the fluid pipeline which is arranged at the rising edge or the falling edge of the square wave is fixedly connected with the heat pipes. The other part of the fluid pipeline is arranged among the heat pipes and is not in contact with the connecting plates. The heat pipes and the fluid pipelines are arranged on the inner wall of the cylindrical structure. Compared with the fluid pipeline of the existing fluid loop radiator, the fluid loop pipeline of the heat radiator provided by the invention is greatly reduced and the probability that the fluid pipeline is hit by space debris is greatly reduced. Even though the space debris hit the heat pipes and cause the heat pipes to fail because of leakage, only the radiating capacity of a small area where the heat pipes are hit is lost and almost the working of the entire radiator is not influenced. If the space debris hit the fluid pipeline and cause the fluid pipeline to fail because of leakage, an automatic valve can detect the pressure of a hit branch and can isolate the hit branch, and the situation that the entire radiator fails is avoided.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

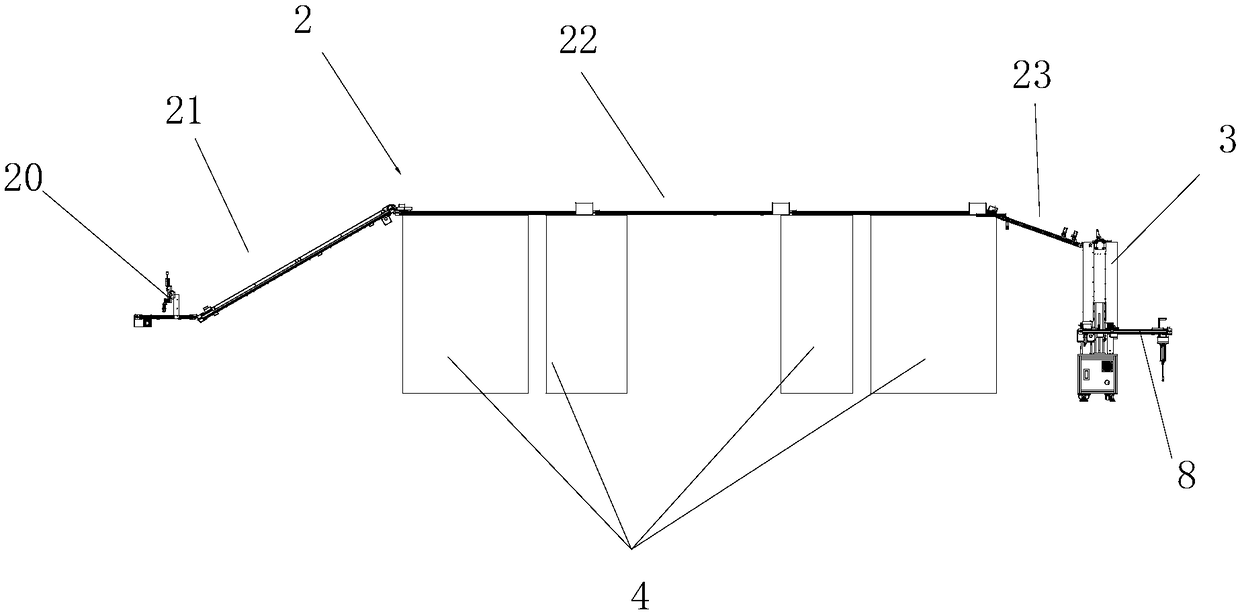

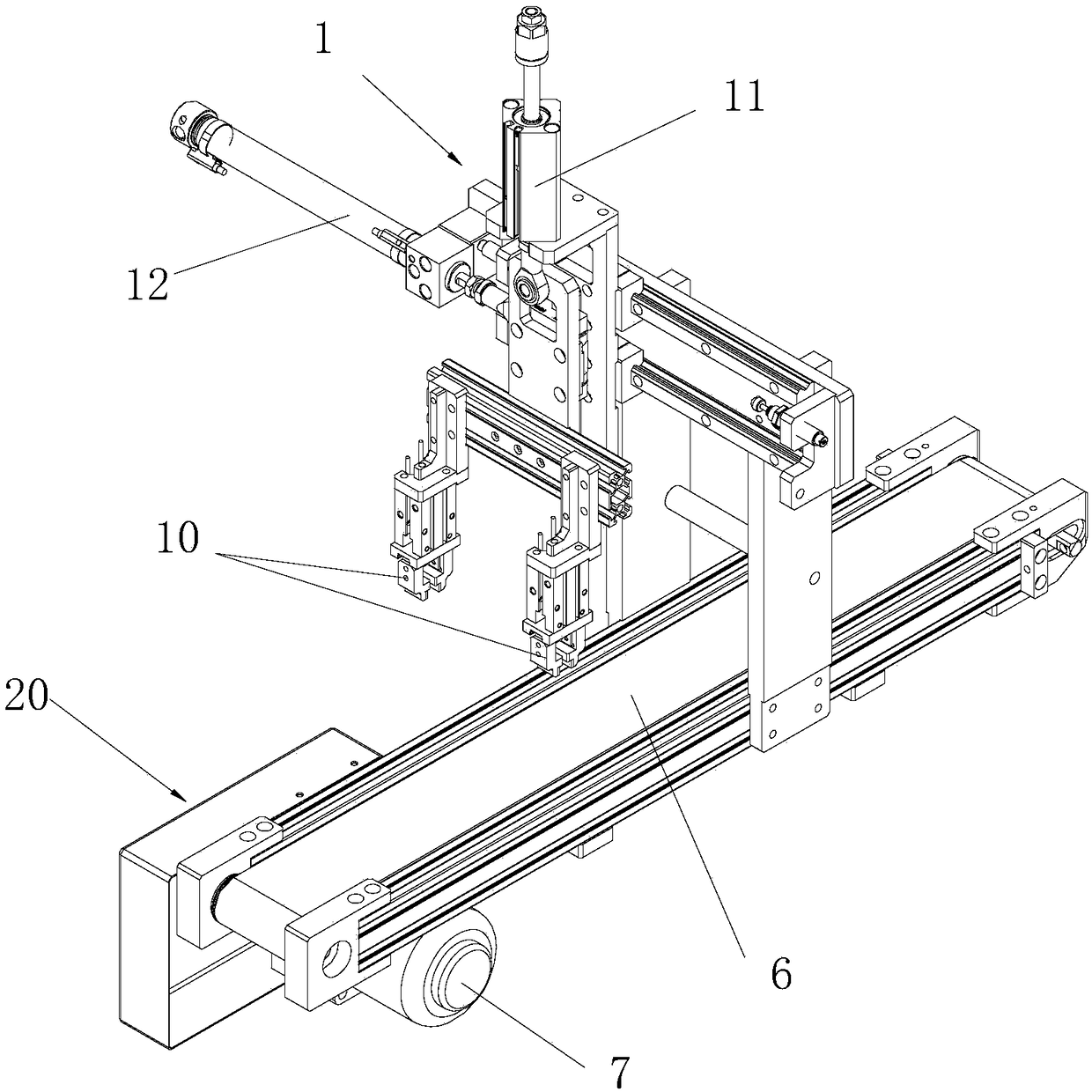

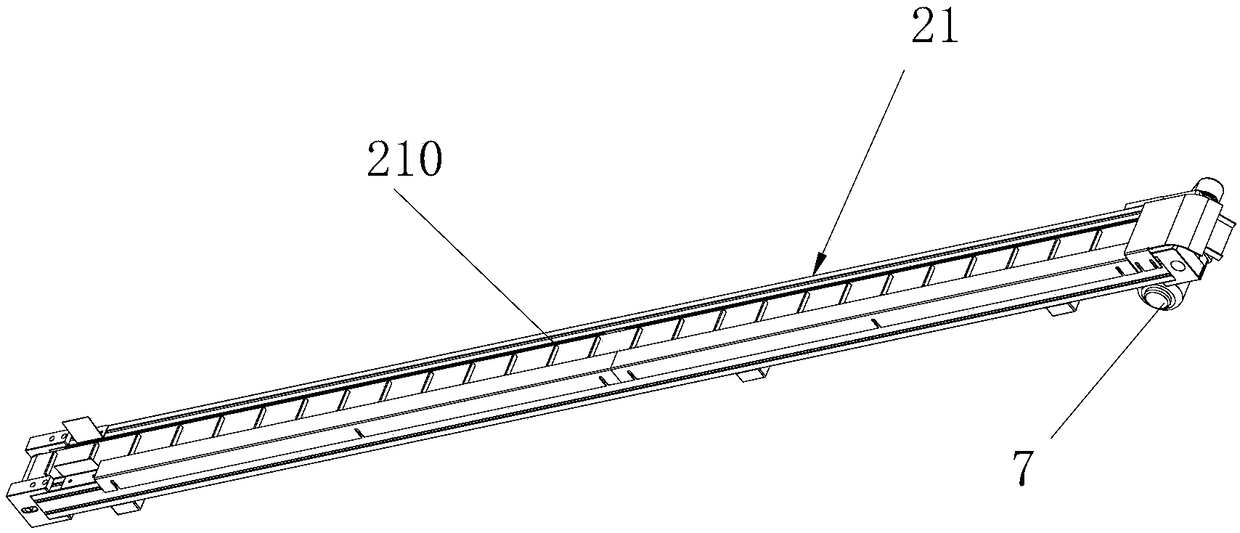

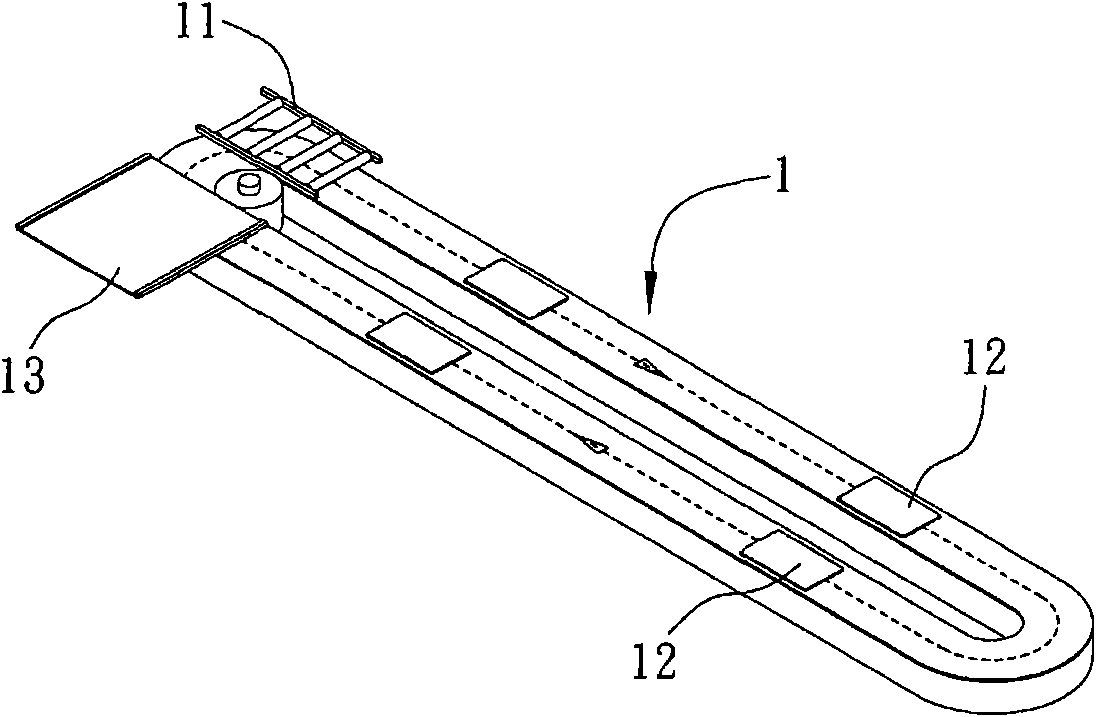

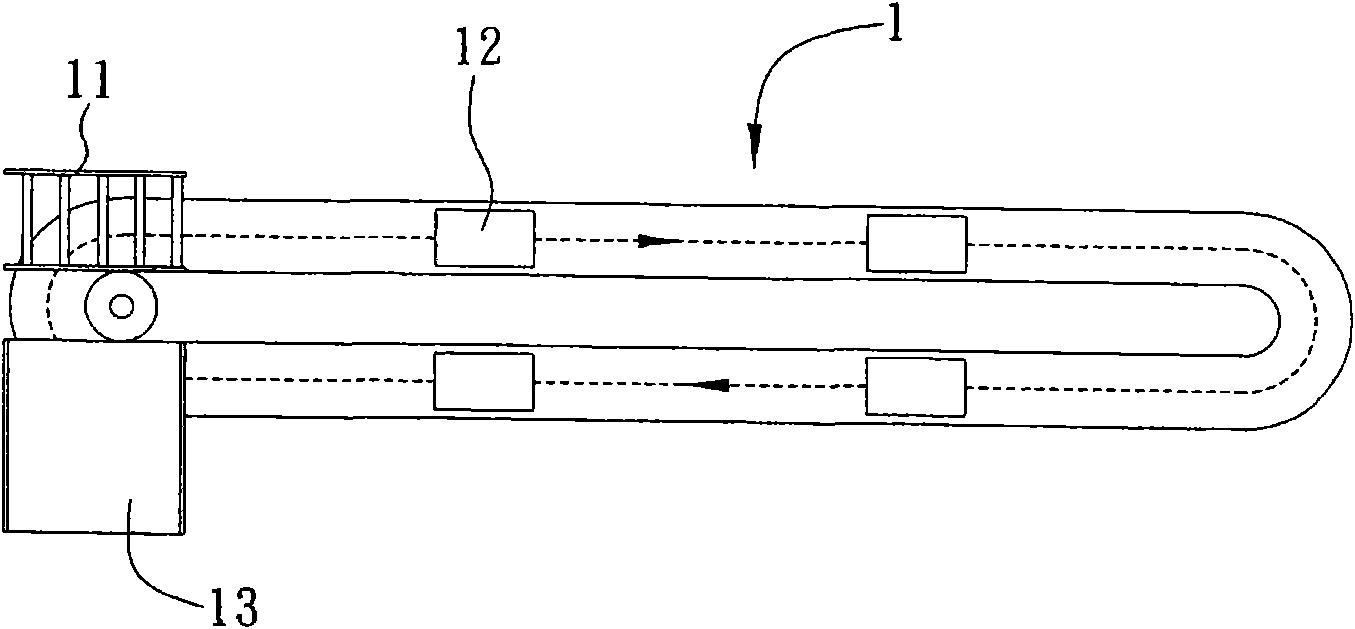

Jig circulation assembly line and jig backflow device

PendingCN108408398AReduce investmentSimple structureConveyorsControl devices for conveyorsAssembly lineManipulator

The invention discloses a jig circulation assembly line and a jig backflow device. The jig backflow device comprises a feeding mechanical hand, a conveying structure and a vertical lifting structure,wherein the feeding mechanical hand is arranged at the input end of the conveying structure, and is used for putting jigs on the conveying structure; the conveying structure is sequentially divided into a rising section, a straight section and a slow descent section from the input end to the output end; the rising section, the straight section and the slow descent section are of belt transmissionstructures; the rising section of the conveying structure is upwards obliquely arranged; the straight section of the conveying structure is horizontally arranged; the input end of the straight sectioncorresponds to the rising section; the output end of the straight section corresponds to the slow descent section; the slow descent section is downwards obliquely arranged; and the vertical lifting structure is arranged at the output end of the conveying structure, and is used for receiving the jigs conveyed by the conveying structure and moving the jigs to a working platform. According to the jig backflow device, the structure is simple, operation is convenient, long-distance assembly line jig backflow can be achieved, jig input is reduced, manpower resource input is reduced, production efficiency is improved, and production cost is reduced.

Owner:SHENZHEN OUSHENG AUTOMATION CO LTD

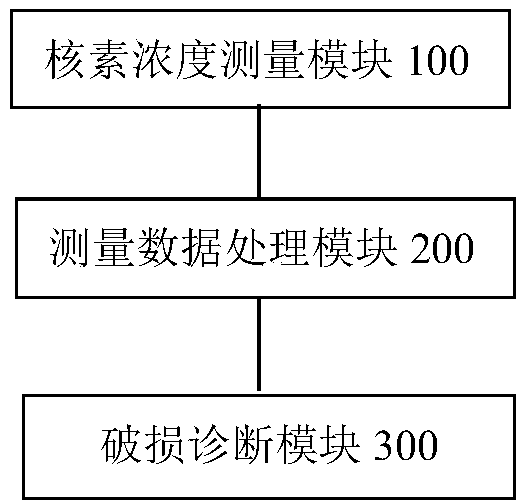

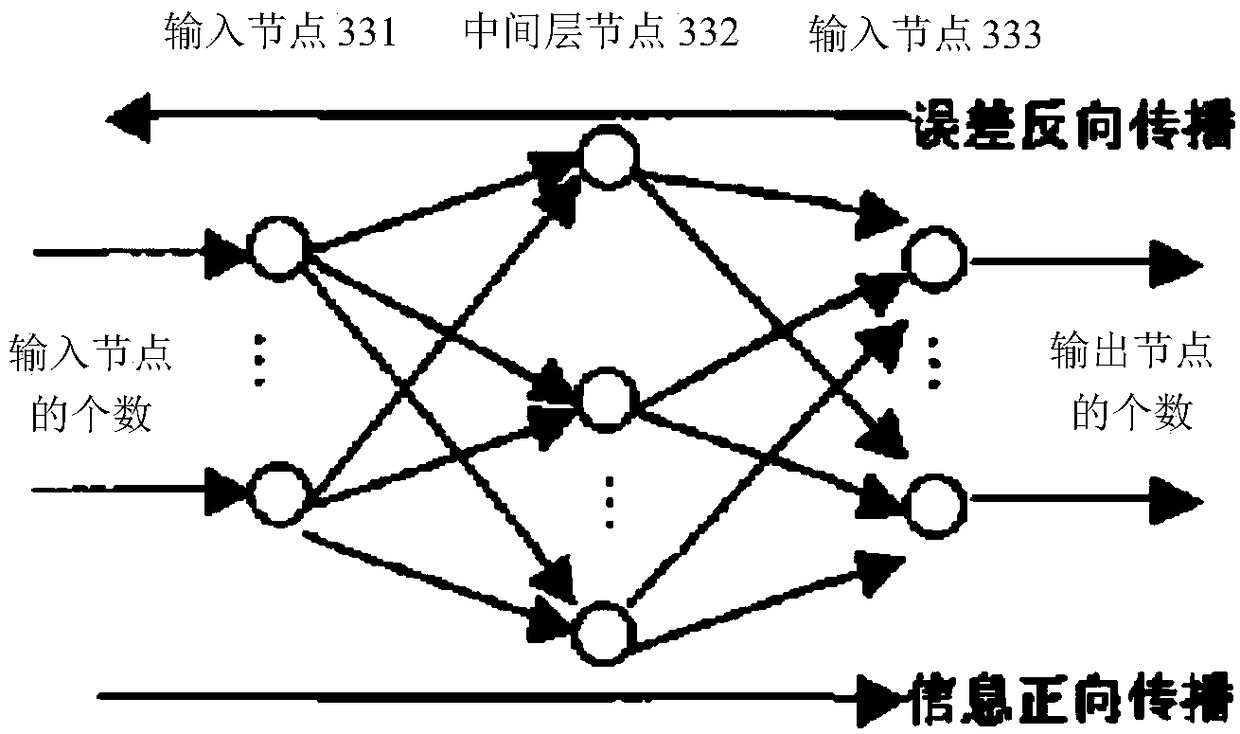

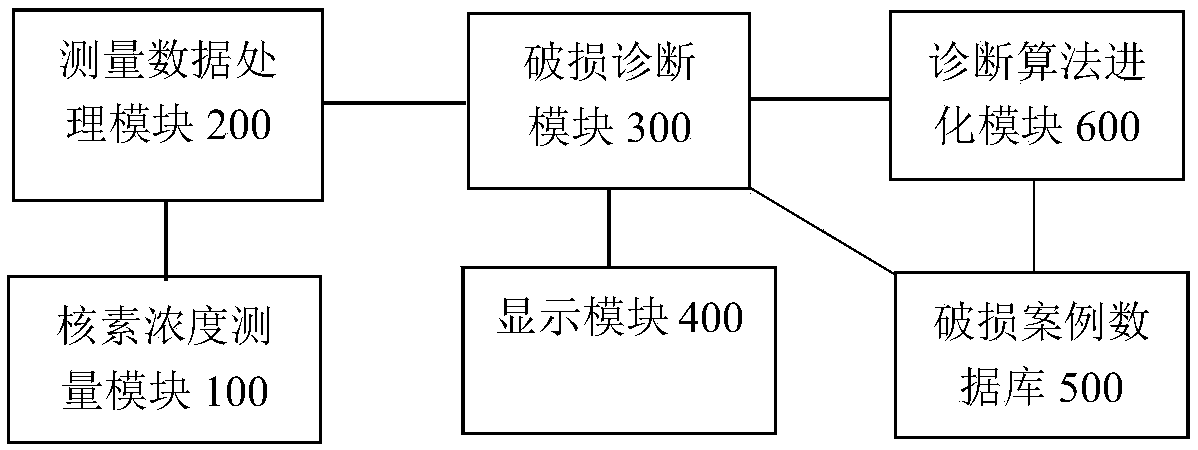

Nuclear power station fuel cladding failure diagnosis system and diagnosis method thereof

InactiveCN109346198AImprove accuracyReduce manual interventionNuclear energy generationNuclear monitoringNuclear powerNuclear engineering

The invention provides a nuclear power station fuel cladding failure diagnosis system and diagnosis method thereof. The nuclear power station fuel cladding failure diagnosis system comprises a nuclideconcentration measuring module, a measuring data processing module and a failure diagnosis module, wherein the nuclide concentration measuring module is arranged outside a nuclear power station primary loop pipeline and used for measuring photon number and photon energy released by each radionuclide in a nuclear power station primary loop coolant within a preset time section; the measuring data processing module is used for receiving the photon number and the photon energy within the preset time section and extracting characteristic nuclide and concentration thereof from the photon number andthe photon energy within the preset time section according to characteristics of the photon energy released by the radionuclide and photon emissivity within a unit time; and the failure diagnosis module is used for receiving the characteristic nuclide and the concentration thereof, adopting a self-evolution diagnosis algorithm to process and analyze the characteristic nuclide and the concentration thereof and diagnosing whether the fuel cladding is broken or not. According to the nuclear power station fuel cladding failure diagnosis system and diagnosis method, online continuous monitoring and diagnosis of nuclear power station fuel cladding integrity during power operation period are realized, and self-evolution of the diagnosis algorithm is also realized.

Owner:CHINA NUCLEAR POWER DESIGN COMPANY +3

Circular assembly line and method for assembling product by using same

InactiveCN101642874ASpace does not affect each otherSave human resourcesAssembly machinesMechanical conveyorsAssembly lineWork in process

The invention relates to a circular assembly line and a method for assembling products by using same. The circular assembly line comprises two first and second assembly areas which can operate independently and integrally, and a carrying frame arranged above the first assembly areas and the second assembly areas is used to temporarily store semi-finished products assembled in the first assembly areas, and transport the semi-finished products to the second assembly areas so as to carry out subsequent processing to the semi-finished products to produce finished products and deliver goods The circular assembly line and the method save cost by reasonably controlling product packaging line production, performing local operational steps in advance and reasonably using labor and power resources.The invention also provides the method for assembling products by using the circular assembly line.

Owner:INVENTEC CORP

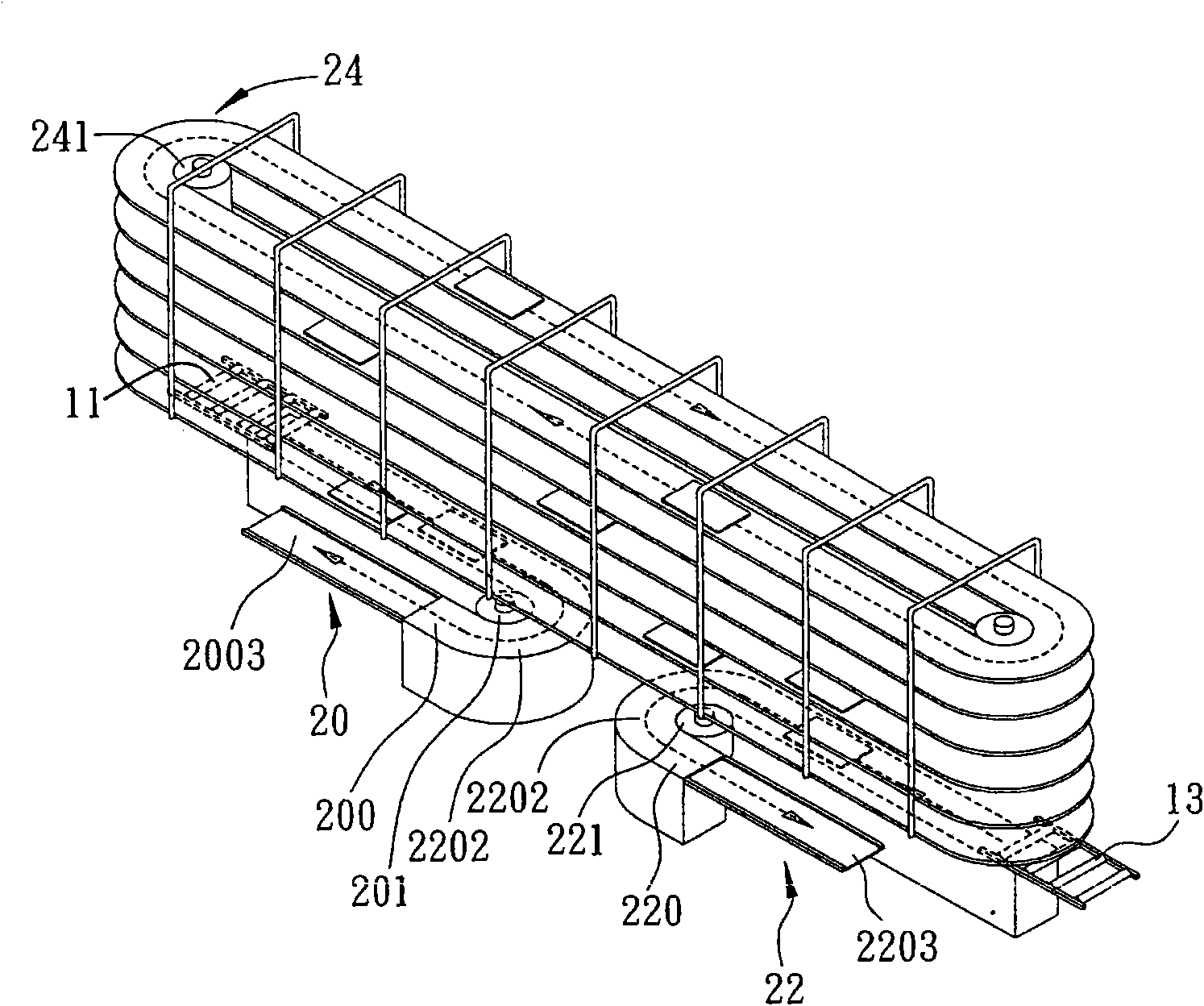

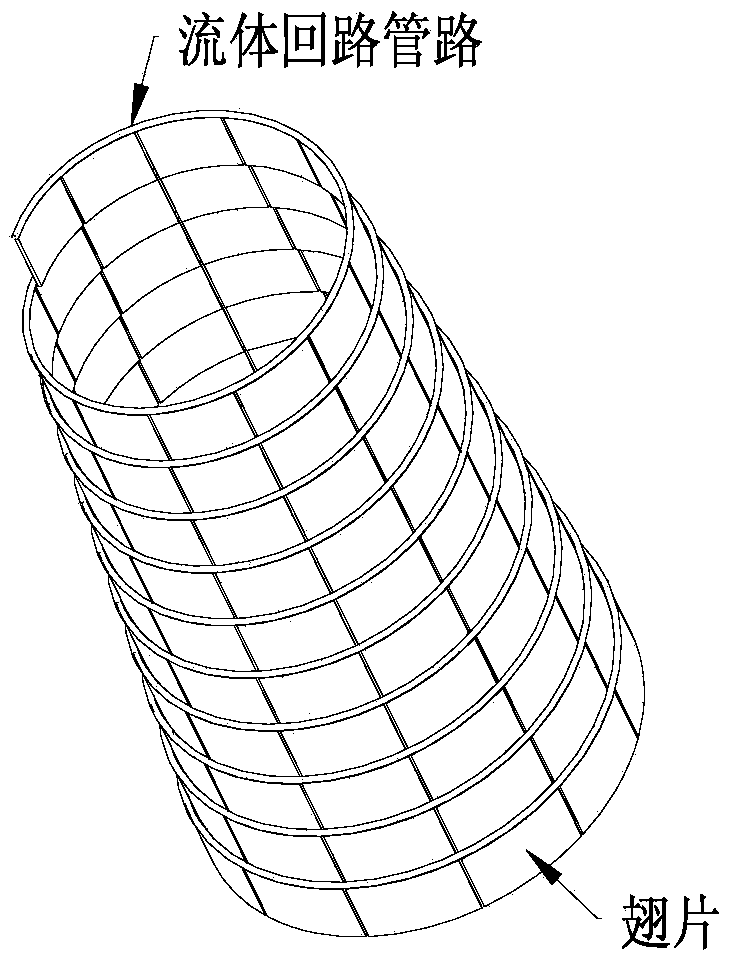

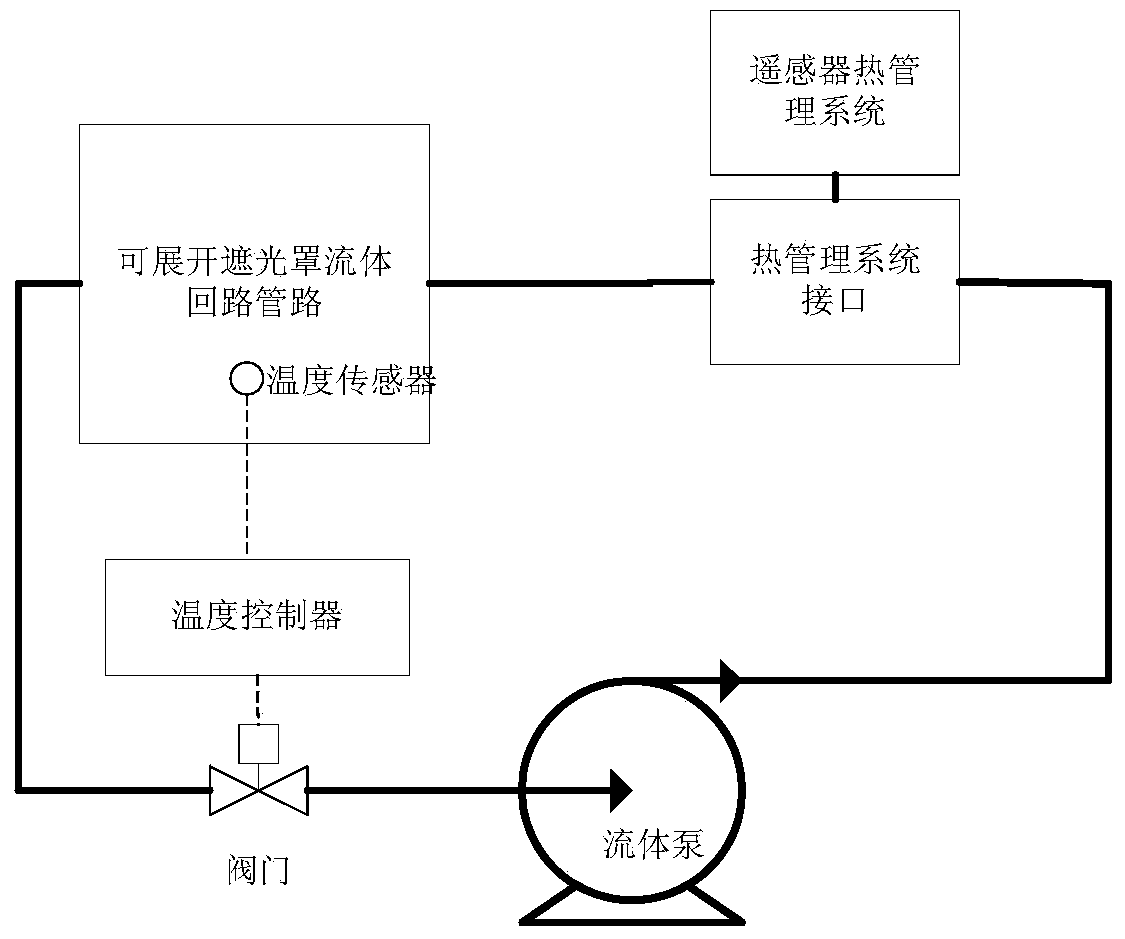

A deployable light shield

ActiveCN103645756ASolve the problem of temperature controlGuaranteed uniformityTemperatue controlTemperature controlImaging quality

The invention discloses a deployable light shield comprising fluid loop pipelines, fins, a heat insulation assembly and a temperature control system. The deployable light shield designed by the invention has a fluid temperature control function, and solves temperature control problems of existing large aperture optical remote sensor deployable light shields. When sunshine directly shines on the fins or fluid loop pipelines inside the light shield, heat is rapidly taken away through the fluid loops, so that a rapid temperature equalizing effect is realized, and the uniformity and stability of optical lens are ensured, and the quality of imaging is raised. In addition, the fluid loops can provide an auxiliary adjusting effect for a heat control system of a whole machine of a remote sensor.

Owner:BEIJING AEROSPACE HEZHONG TECH DEV

Closed-loop-type liquid heavy metal mechanical pump performance testing device

ActiveCN104047870AWon't enterAvoid it happening againPump controlNon-positive displacement fluid enginesMelting tankResearch Object

The invention discloses a closed-loop-type liquid heavy metal mechanical pump performance testing device. The closed-loop-type liquid heavy metal mechanical pump performance testing device comprises a melting tank, an expansion box, a storage tank, a liquid collecting box, a mechanical pump, a main loop pipeline, a valve, a flow meter, a heavy metal pressure gauge, a liquid level meter, a flow guiding pipeline, a gas source, a vacuum pump, a heating thermal-insulation layer, an experience section and the like. The mechanical pump is a driving force source of the whole device and is a tested and researched object. The outlet flow of the pump is changed by adjusting the valve, flow data are obtained through the flow meter, inlet and outlet pressure head (lift) data of the mechanical pump are obtained through the pressure gauge and the two sets of data are combined so that a mechanical pump hydraulic characteristic curve can be drawn through a mature theoretical calculation formula and used for assessing and testing the hydraulic efficiency and the work performance of the mechanical pump. A branch circulation loop is specially designed so that gas in the pipeline can be completely exhausted, the main loop pipeline can be fully filled with liquid metal fluid media in the whole testing process, and the testing accuracy can be guaranteed.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

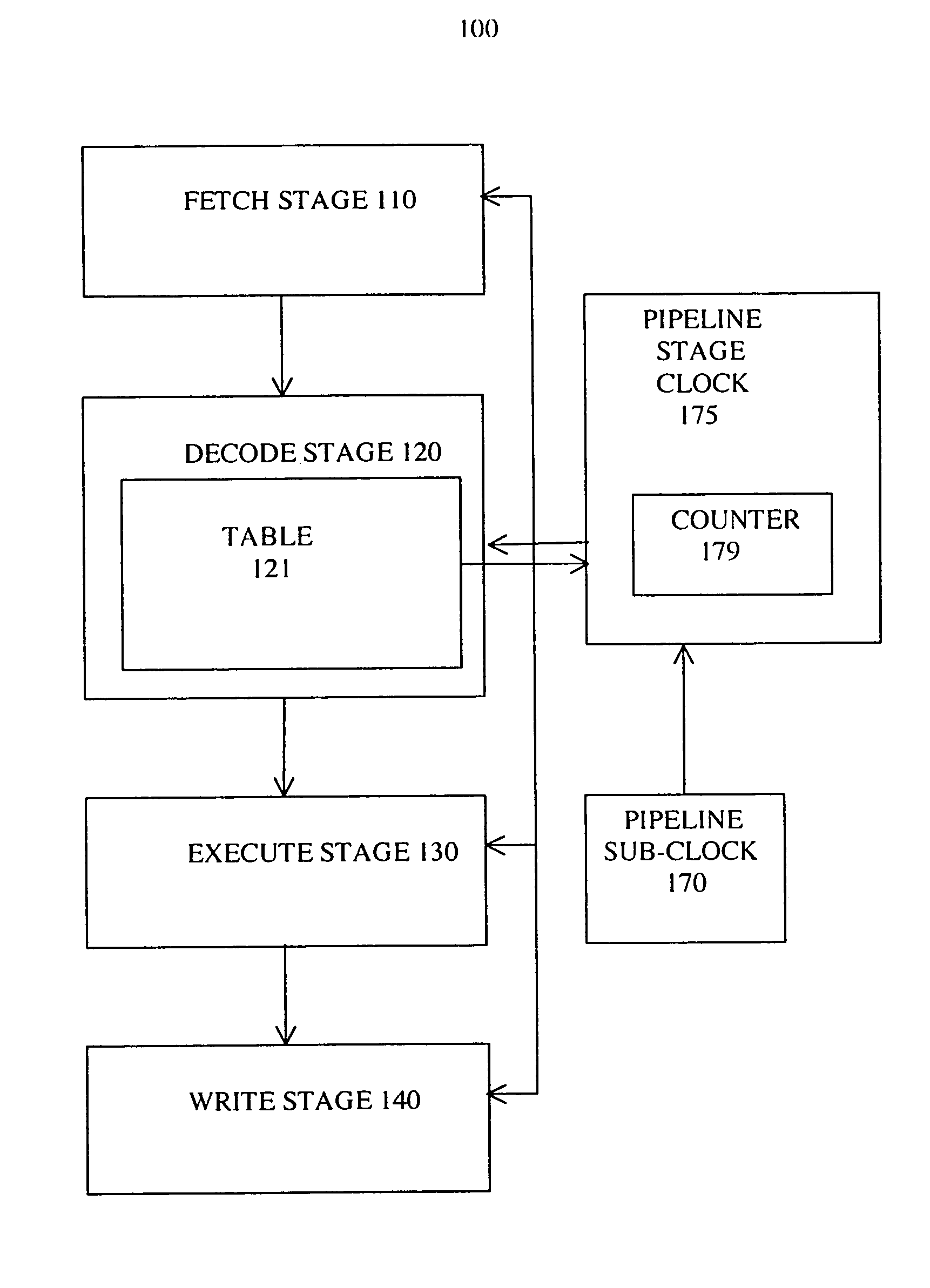

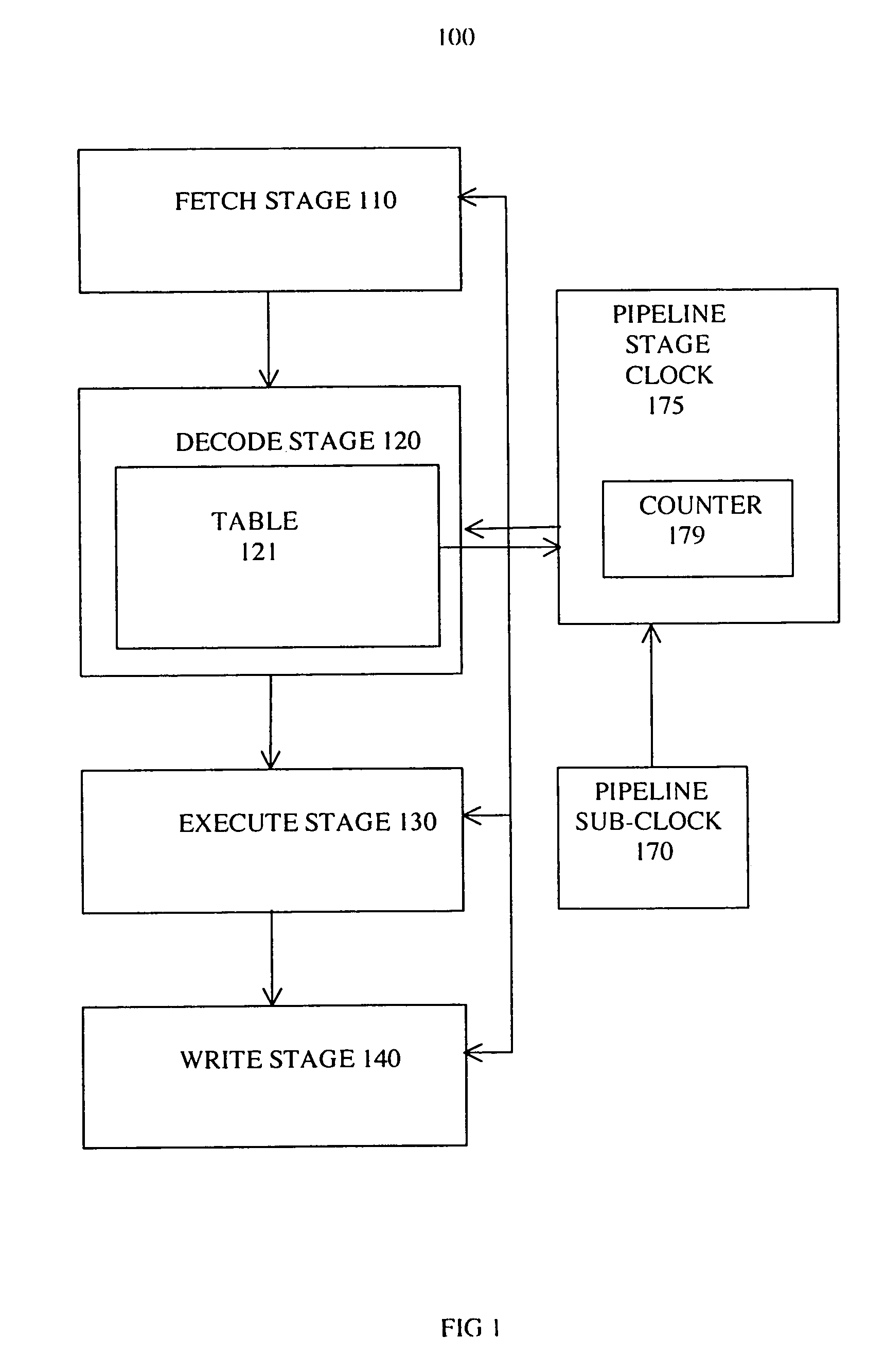

Adjustable cycle pipeline system and method

The present invention utilizes an asynchronous pipeline cycle to facilitate increased average pipeline processing speed. Present invention adjustable cycle pipeline systems and methods minimize “stalls” in execution stages that would otherwise be required to compensate for differences in execution periods. In one embodiment, an adjustable cycle pipeline system includes a fetch stage, a decode stage, an execution stage, and a write stage. The fetch stage fetches information associated with an operation. The decode stage decodes the instructions including determining an instruction execution period. The execution stage executes instructions in accordance with the execution period and the write stage writes the results. In one exemplary implementation the instruction execution period corresponds to a particular number execution sub-clock cycles and the decode stage includes a decode operation timetable for indicating a period of time to complete execution of an operation. The sub-clock controls operations of the execution stage.

Owner:NVIDIA CORP

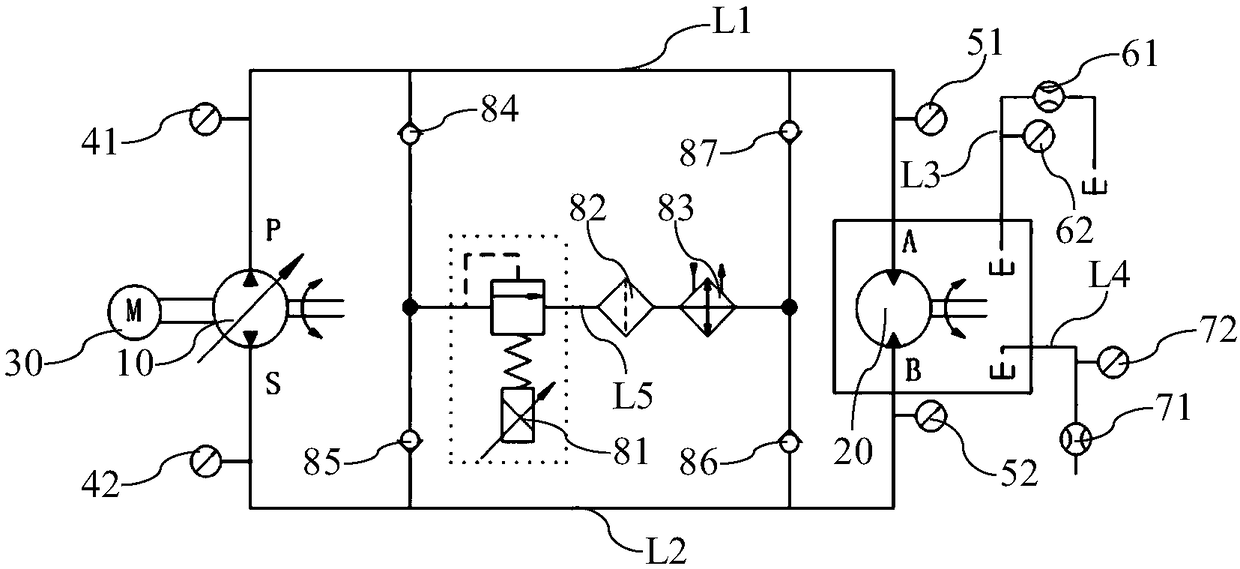

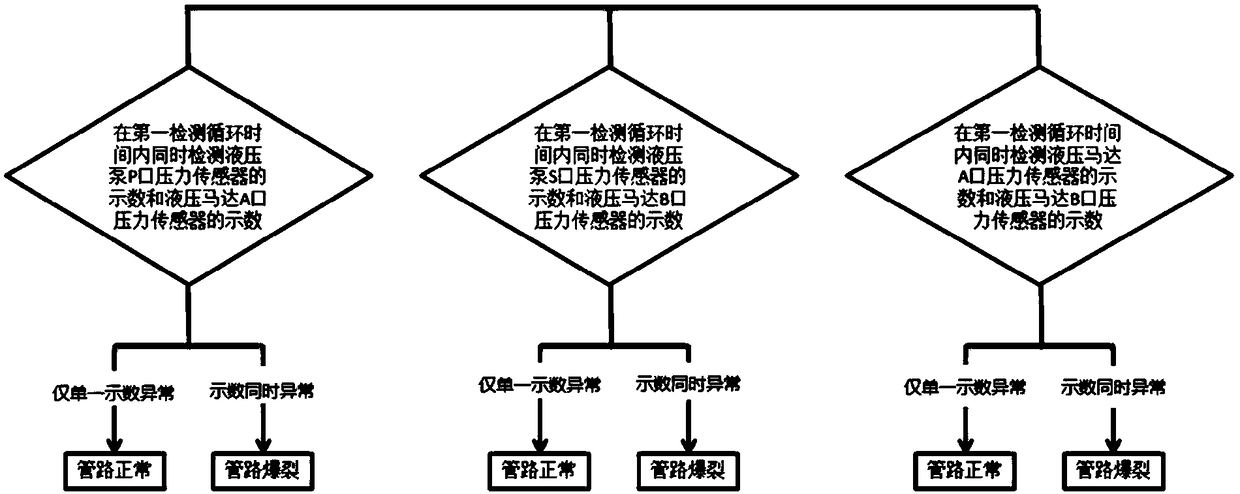

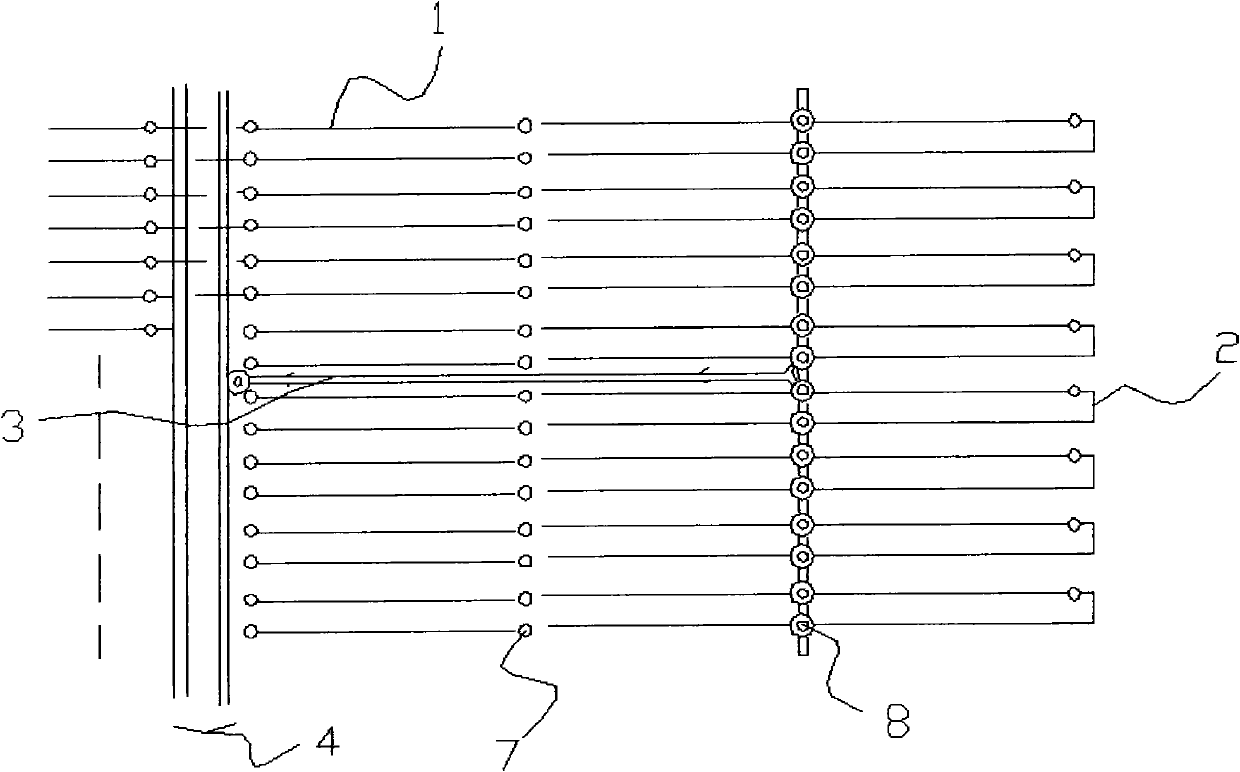

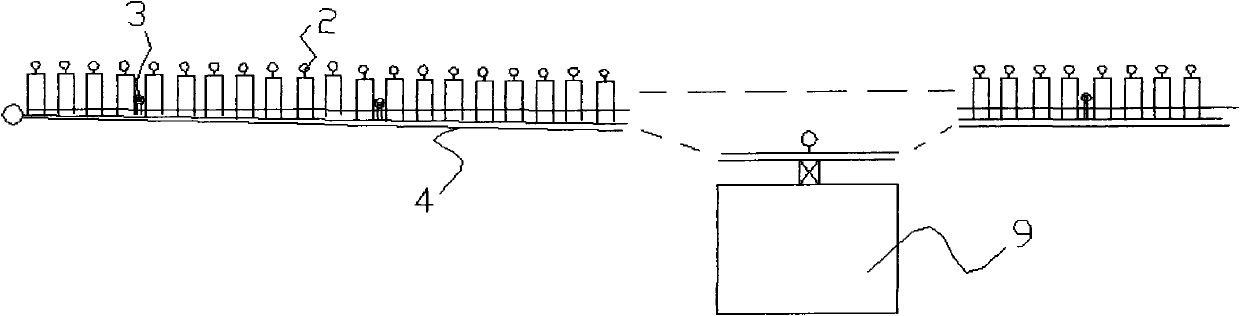

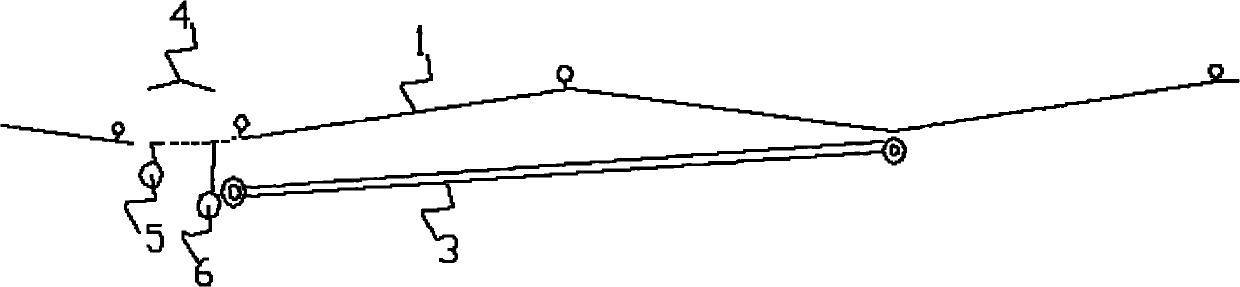

Pipe burst detecting system for endurance test of hydraulic motor and detecting method

ActiveCN108953295AImprove accuracyAvoid failureFluid-pressure actuator safetyFluid-pressure actuator testingHydraulic motorClosed loop

The invention belongs to the technical field of hydraulic loop pipeline detection, and in particular, relates to a pipe burst detecting system for an endurance test of a hydraulic motor and a detecting method. The pipe burst detecting system for the endurance test of the hydraulic motor comprises a hydraulic pump and a hydraulic motor, which form a hydraulic system loop; a closed loop of an overflow valve is connected between the hydraulic pump and the hydraulic motor; a hydraulic pump P port pressure sensor is arranged in a P port of the hydraulic pump; a hydraulic pump S port pressure sensoris arranged in an S port of the hydraulic pump; a hydraulic motor A port pressure sensor is arranged in an A port of the hydraulic motor; and a hydraulic motor B port pressure sensor is arranged in aB port of the hydraulic motor. The pipe burst detecting system for the endurance test of the hydraulic motor and the detecting method prevent failed detecting results caused by errors of the sensors,improve the pipe burst detecting accuracy, are quick in response, and reduce the economical loss and the production delay caused by the pipe burst phenomenon.

Owner:WEICHAI POWER CO LTD +1

Loop design for slot type solar heat power plant

InactiveCN102168890AEnsure safetyAvoid corrosionSolar heating energySolar heat devicesCollector deviceEngineering

The invention discloses a loop design for a slot type solar heat power plant, and relates to the technical field of slot type solar heat power generation. The loop is arranged in a slot type solar heat collecting field; the heat collecting field is divided into a plurality of heat collector units; one of the heat collector units comprises a parabolic glass surface capable of tracking and concentrating sunlight, and a heat collecting pipe placing on the focus line of the parabolic glass surface, each heat collector unit forms a small dip angle with the ground to lead the relative altitude difference between the two ends of the heat collector unit to not exceed 1m. The loop design is characterized in that: the heat collecting pipes of two neighboring heat collector units are connected; then the highest position or the lowest position of the pipelines of the heat collection pipes are formed at the connected part of two neighboring heat collector units; a molten salt recycling valve is arranged at the lowest position of the pipelines of the heat collection pipes, then the heat collection pipes are connected with a recycled molten salt collecting loop through the valve; and a high-temperature high-pressure nitrogen valve is arranged at the highest position of two neighboring heat collector units. The molten salt in a loop pipeline can be completely conveyed to a big heat storage tank for storage in case of needing; in this way, not only is the heat energy loss due to the falling of temperature at night reduced, but also the pipeline safety is guaranteed.

Owner:杭州沃理香管理咨询有限公司

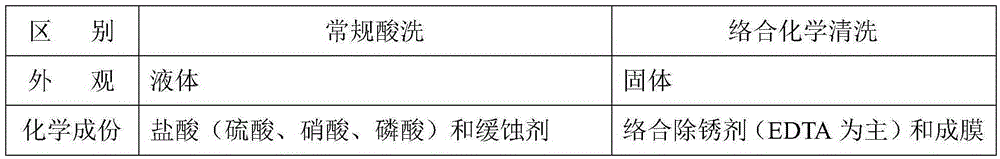

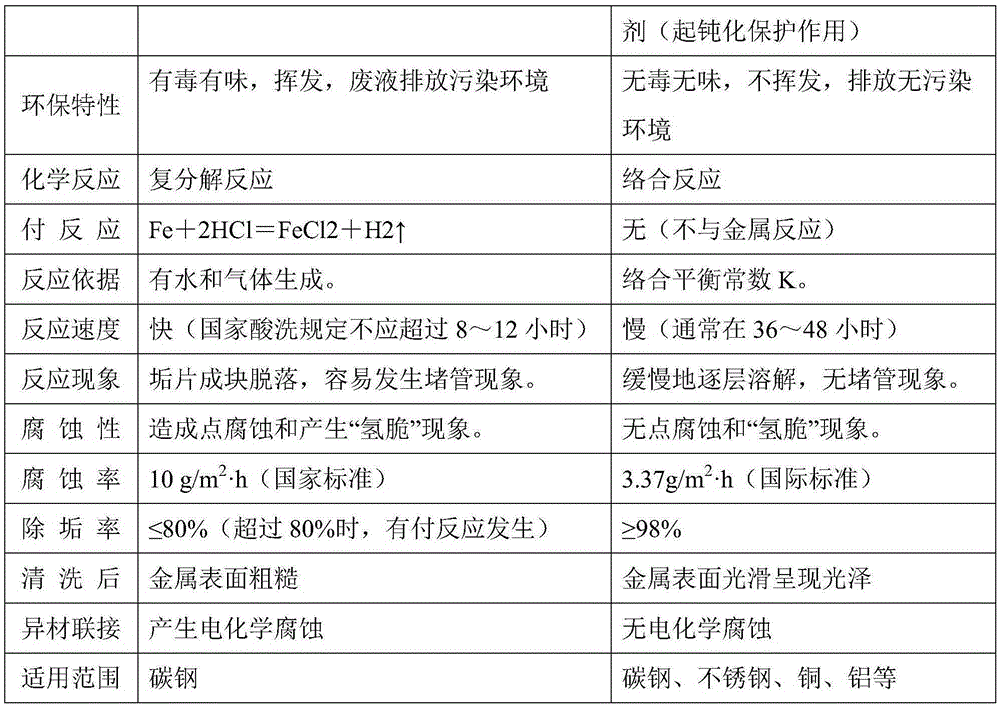

Chemical complexing cleaning method for polycrystalline silicon equipment

ActiveCN105256320AAvoid corrosion damageImprove cleanlinessMetallic material coating processesAcid washingAssembly line

The invention provides a cleaning device for polycrystalline silicon storage tank equipment. A chemical complexing cleaning and equipment cleaning process is a new environment-friendly technical revolution of traditional acid and alkali cleaning. A complexing agent which is free of toxicity and smells, not volatile and free of pollution to the environment during emission is adopted for cleaning, various problems in polycrystalline silicon cleaning are completely solved, and corrosion damage of acid washing to equipment materials is avoided. Immersion type cyclic assembly line work can be adopted, the capacity of pipeline cleaning of the polycrystalline silicon equipment can be increased by 3-5 times, and the cleaning time of the polycrystalline silicon equipment can be greatly shortened.

Owner:陕西庄臣环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com