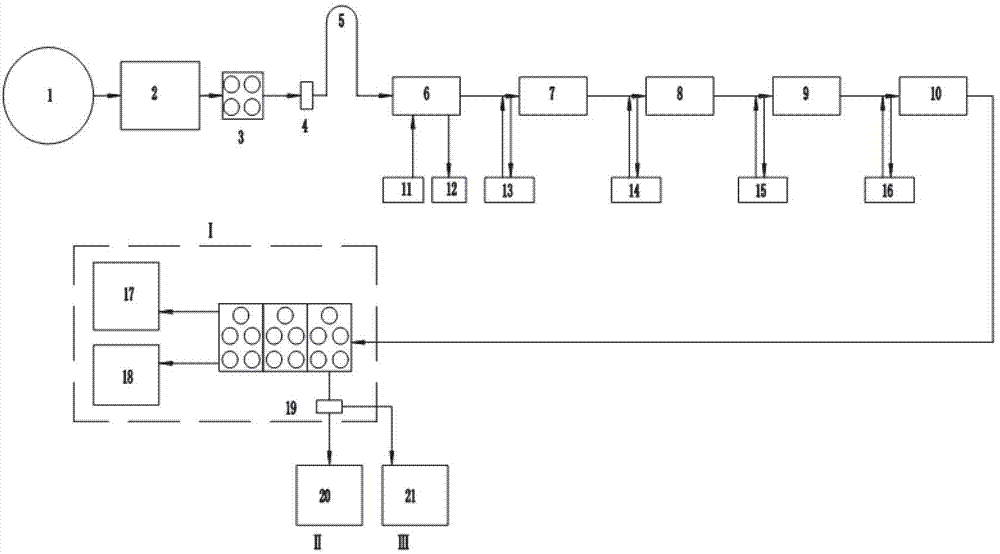

Large-volume long-distance airtight relay pipeline coal handling system and method

A technology of coal conveying system and transportation system, which is applied in the direction of transportation and packaging, conveyors, and conveying bulk materials. The occurrence of traffic accidents, the ease of use and operation, and the effect of reducing transportation pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

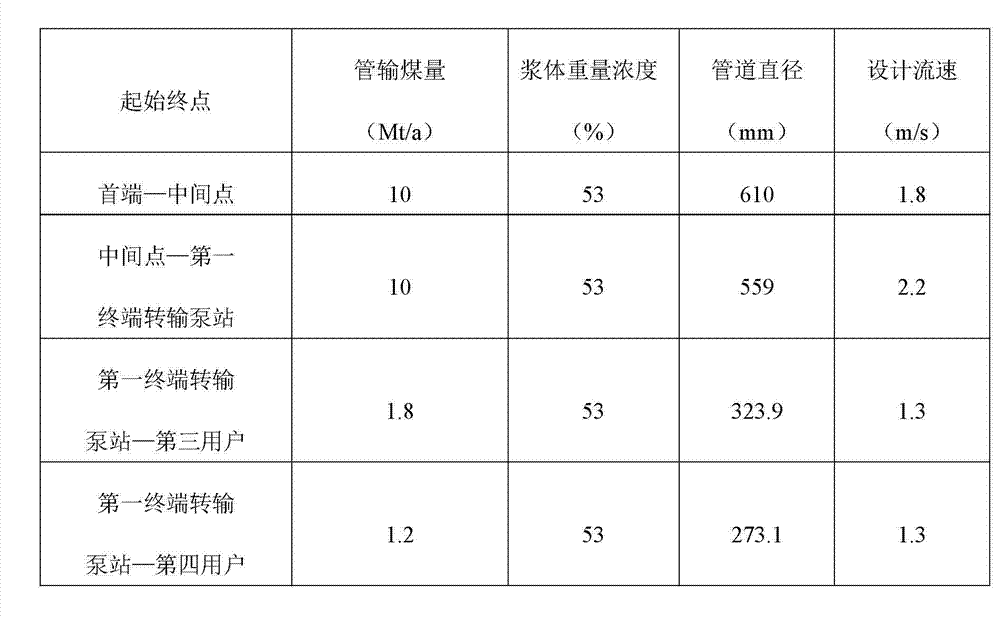

[0055] 1. Main design parameters of pipeline transportation process

[0056] 1. Design coal slurry concentration, flow velocity and pipe diameter

[0057] The weight of the coal slurry in this design is 53%, and the pipeline transportation flow rate must meet the requirements of safe flow velocity and transportation volume at the same time. The selection of pipeline transportation concentration, flow velocity and pipe diameter of this project is shown in Table 4-4-2.

[0058] Pipeline Diameter Corresponding to Design Velocity Table

[0059] Table 4-4-2

[0060]

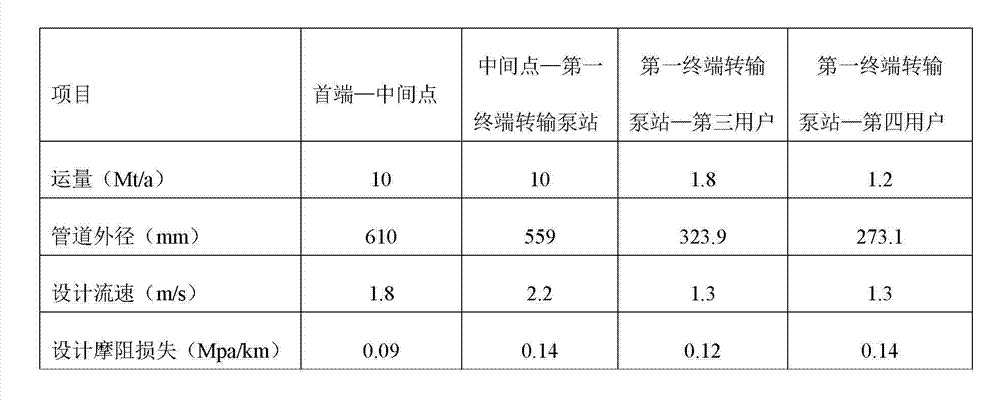

[0061] 2. Conveying resistance

[0062] According to the selected pipe diameter and transport concentration, and according to the laboratory experiment data, design the resistance at the design flow rate of each section of the pipe as shown in Table 4-4-3.

[0063] List of pipe diameter and friction loss

[0064] Table 4-4-3

[0065]

[0066] 3. Pipeline flow

[0067] See Table 4-4-4 for the normal deliver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com