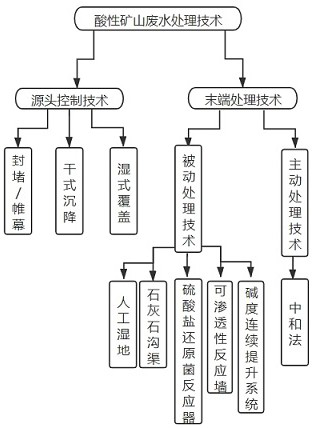

Modular acid mine wastewater treatment equipment

A technology for acid mine wastewater and treatment equipment, which is applied in mining wastewater treatment, water/sewage treatment equipment, water/sewage treatment, etc. Lack of preliminary investigation and other problems, to solve the problems of acidification and heavy metal pollution, improve the availability of resources, and achieve the effect of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention is further illustrated by the following examples.

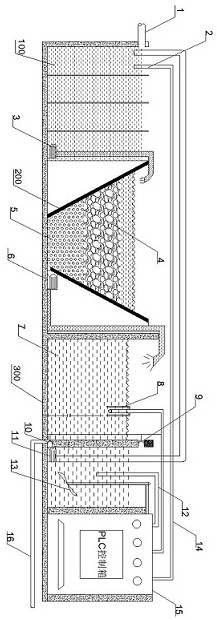

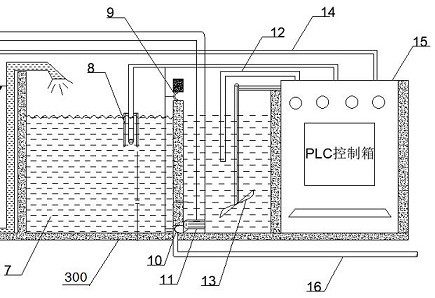

[0046] A modular acid mine wastewater treatment equipment, including a flocculation sedimentation tank 100, a regulating tank 200, a clear water tank 300 and a control room 15 connected to each treatment tank, the flocculation sedimentation tank 100 is connected to the water inlet 1, and the flocculation sedimentation The pool 100 is connected to the regulating pool 200, and the regulating pool 200 is connected to the clean water pool 300. The regulating pool 200 is provided with a first regulating module 4, and the first regulating module 4 includes an installation frame 27, and the first regulating module 4 is arranged in the mounting frame 27. The material part 26, the first material storage part 26 is filled with a first mixture, the first mixture is a mixture of sludge charcoal, organic fertilizer, and palygorskite, and a second adjustment module 5 is arranged below the first adjustment module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com