A coal distribution device

A technology of coal and land sales, applied in the field of machinery, can solve the problems of heavy environmental and traffic burdens, heavy maintenance workload, and large power consumption, and achieve the effects of reducing coal transportation pressure, high automation efficiency, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings.

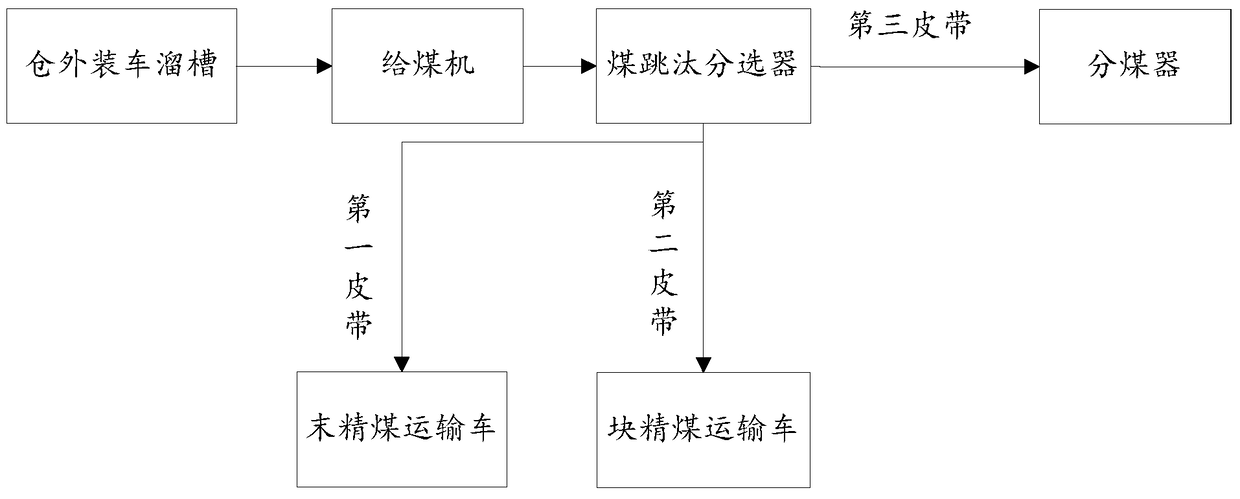

[0023] In one embodiment, as figure 1 As shown, a kind of coal ground pin collection and distribution device includes a loading chute outside the warehouse, a coal feeder, a coal jigging separator, a rail running belt and a coal separator, and the rail running belt includes a first belt, a second belt and a coal separator. third belt;

[0024] Coal is divided into fine coal, lump clean coal and coking coal through the loading chute outside the warehouse, coal feeder and coal jigging separator. The three kinds of coal are transported by the first belt, the second belt and the third belt respectively. The items carried by the first belt and the second belt are directly loaded and transported at the end of the belt, and the items carried by the third belt are sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com