Steam-vapour three-purpose pipe distributing method of iron

A technology for piping arrangement and steam, applied in applications, hand irons, washing devices, etc., can solve the problem of not being suitable for various occasions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

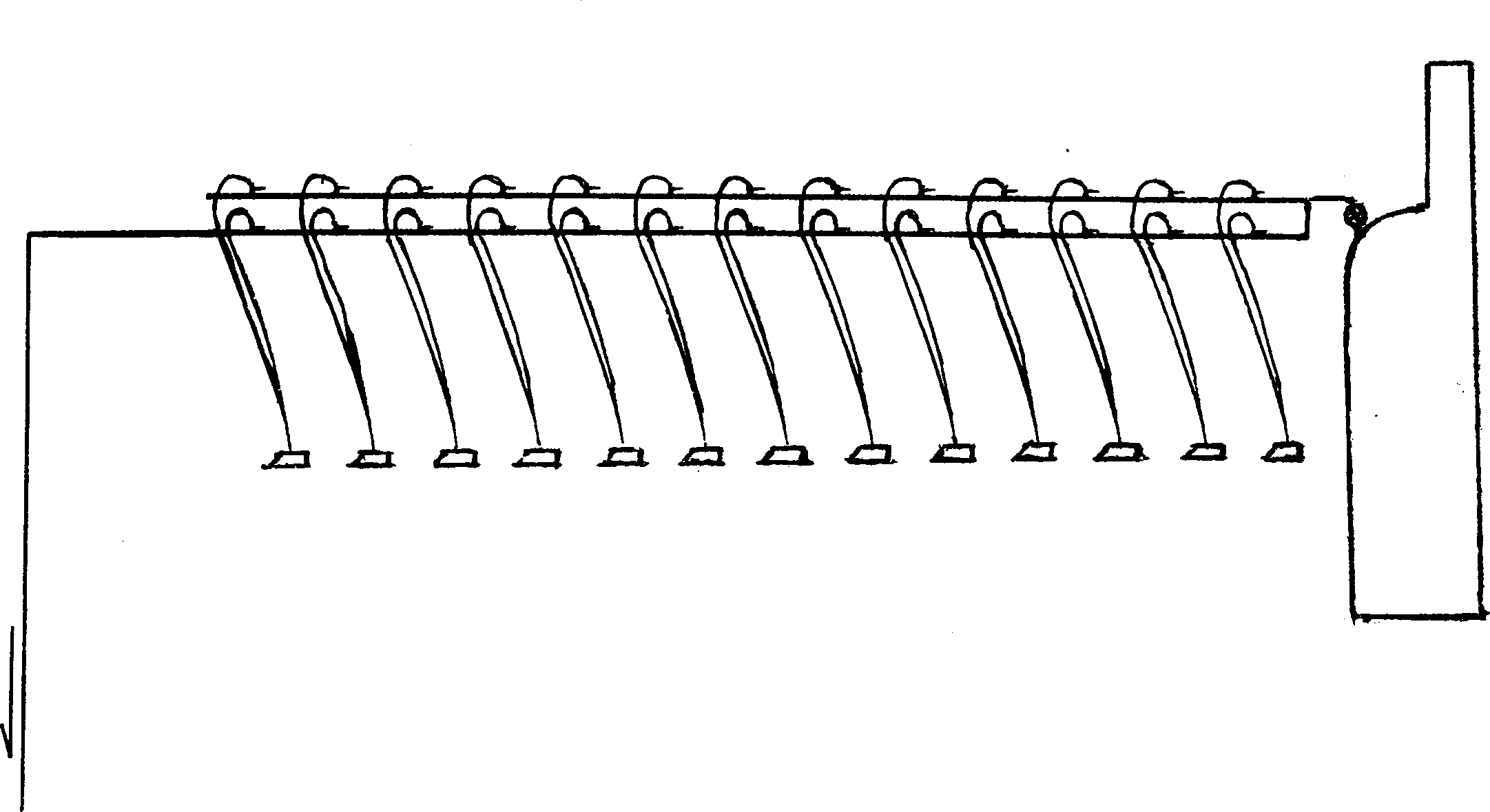

Image

Examples

Embodiment Construction

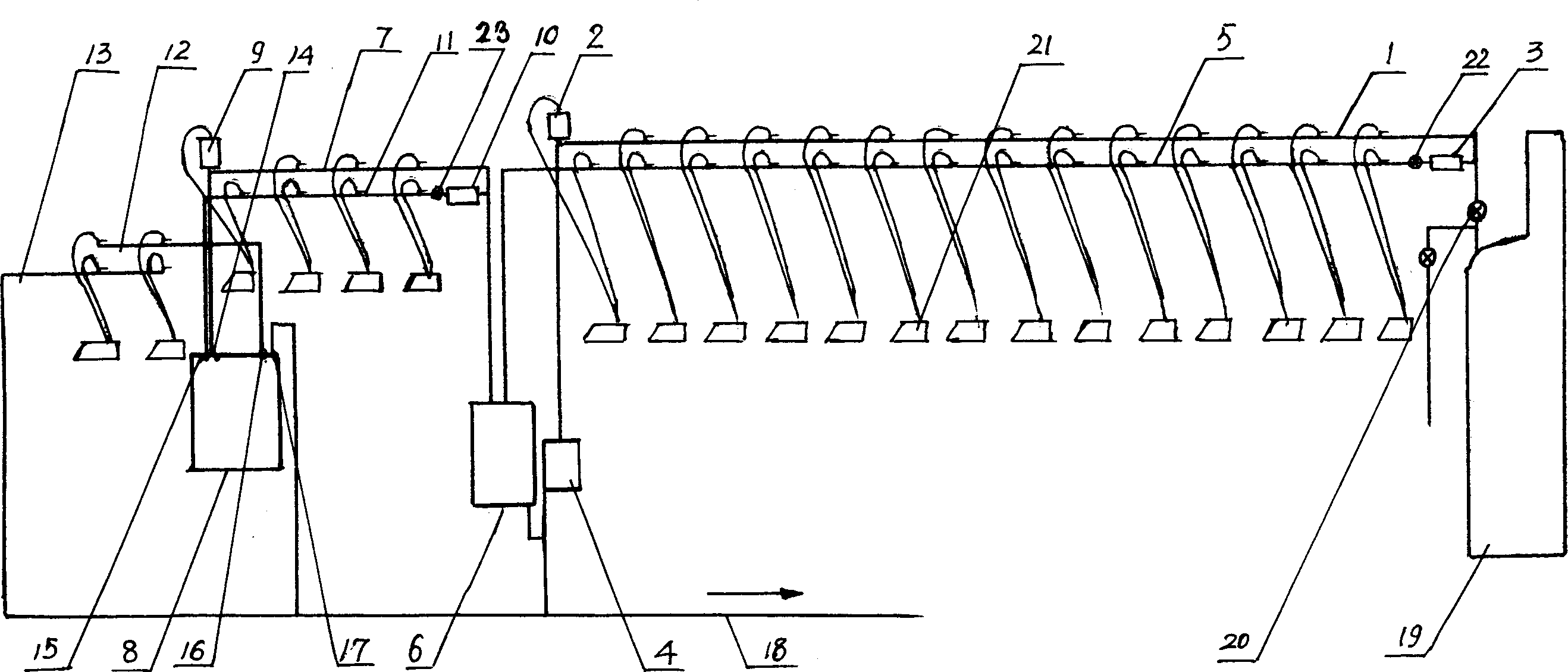

[0009] The present invention and its positive effects will be further described below in conjunction with the embodiments and accompanying drawings.

[0010] see figure 2 , an iron steam three-purpose pipeline layout method, the steam iron 21 in one unit is divided into three areas, namely A area, B area and C area, and the main pipeline 1 of A area is connected to the boiler 19 through the steam main valve 20 , the tail of the main pipe 1 in area A is equipped with a steam water filter 4, the turning of the main pipe 1 in area A is equipped with a steam trap 2, the auxiliary pipe 5 in area A is the iron tail steam pipe in area A and the main pipe 1 in area A The middle of the connection is equipped with a steam self-control compensator 3, the tail of the auxiliary pipe 5 in area A is connected to the steam-water separator 6, the auxiliary pipe 5 in area A passes through the steam-water separator 6 and becomes the main pipe 7 in area B, and the main pipe 7 in area B The tail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com