Preparation method of environment-friendly quartzite plate

A quartz stone plate and environmental protection technology, which is applied in the field of preparation of environmentally friendly quartz stone plates, can solve the problems of insufficient water absorption and antifouling properties, reduction of the overall mechanical properties of the quartz stone plate, and influence on the quality of the quartz stone plate, so as to improve the overall mechanical properties of the quartz stone plate. The effect of improving the performance, improving the density, and improving the range of deformation adaptation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

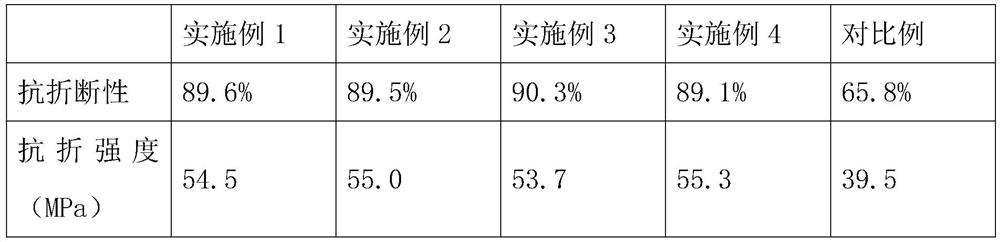

Examples

Embodiment 1

[0029] A method for preparing an environmentally friendly quartz stone plate, specifically comprising the following steps:

[0030]Step 1, pass the quartz sand and the pigment together into the ball mill pasted with aluminum oxide for 5 hours, then pass the mixture of the quartz sand and the pigment together with tourmaline and silicon micropowder into the planetary high-speed mixer, Under the condition that the rotation speed is 1200rpm, stir for 20min to obtain a uniformly dispersed base material;

[0031] Step 2. Use a mixer to continue stirring the base material at a speed of 600 rpm. During the stirring process, add unsaturated polyester resin to the inside of the mixer, stir for 30 minutes, and finally add quartz powder to the inside of the mixer, and continue stirring for 10 minutes to obtain an intermediate;

[0032] Step 3, adding a curing agent and a coupling agent to the intermediate, stirring at a speed of 850 rpm, and stirring for 30 minutes to obtain a quartz sto...

Embodiment 2

[0047] A method for preparing an environmentally friendly quartz stone plate, specifically comprising the following steps:

[0048] Step 1, pass the quartz sand and the pigment together into the ball mill pasted with aluminum oxide for 5 hours, then pass the mixture of the quartz sand and the pigment together with tourmaline and silicon micropowder into the planetary high-speed mixer, Under the condition that the rotation speed is 1350rpm, stir for 23min to obtain a uniformly dispersed base material;

[0049] Step 2. Use a mixer to continue stirring the base material at a speed of 680 rpm. During the stirring process, add unsaturated polyester resin to the inside of the mixer, stir for 38 minutes, and finally add quartz powder to the inside of the mixer, and continue to stir for 13 minutes to obtain an intermediate;

[0050] Step 3, adding a curing agent and a coupling agent to the intermediate, stirring at a speed of 780 rpm, and stirring for 33 minutes to obtain a quartz sto...

Embodiment 3

[0065] A method for preparing an environmentally friendly quartz stone plate, specifically comprising the following steps:

[0066] Step 1, pass the quartz sand and the pigment together into the ball mill pasted with aluminum oxide for 5 hours, then pass the mixture of the quartz sand and the pigment together with tourmaline and silicon micropowder into the planetary high-speed mixer, Under the condition that the rotation speed is 1500rpm, stir for 28min to obtain a uniformly dispersed base material;

[0067] Step 2. Use a mixer to continue stirring the base material at a speed of 760 rpm. During the stirring process, add unsaturated polyester resin to the inside of the mixer, stir for 43 minutes, and finally add quartz powder to the inside of the mixer, and continue to stir for 16 minutes to obtain an intermediate;

[0068] Step 3, adding a curing agent and a coupling agent to the intermediate, stirring at a speed of 820 rpm, and stirring for 36 minutes to obtain a quartz sto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com