Patents

Literature

31results about How to "Improve supercooling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

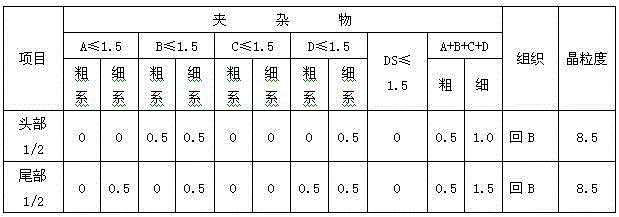

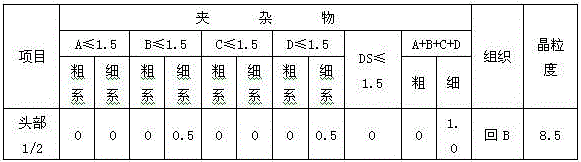

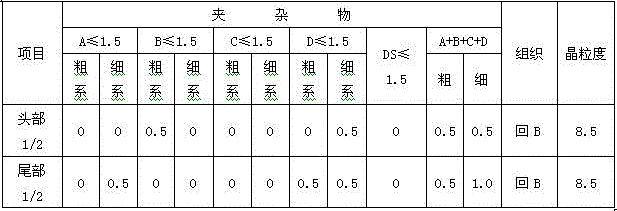

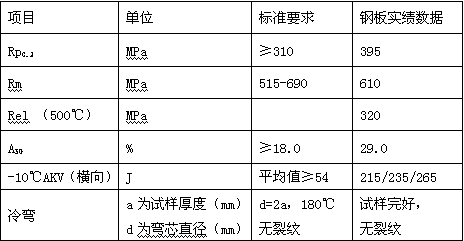

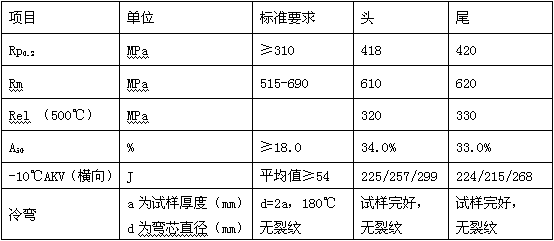

Superlarge thickness hydrogen chromium molybdenum steel plate for hydrogenation equipment and manufacture method thereof

The invention relates to a superlarge thickness hydrogen chromium molybdenum steel plate for hydrogenation equipment and a manufacture method thereof, and belongs to the technical field of ferrous metallurgy. A technical scheme is as below: the steel plate comprises the following components by weight: no more than 0.15% of C, no more than 0.10% of Si, 0.300.60% of Mn, no more than 0.007% of P, no more than 0.005% of S, 2.00-2.50% Cr, 0.90-1.10% of Mo, no more than 0.02% of Nb, no more than 0.20% of Cu, no more than 0.20% of Ni, no more than 0.003% of Sb, no more than 0.005% of Sn, no more than 0.016% of As, no more than 0.003% of O, N no more than 0.008%, no more than 0.0002% of H, no more than 0.03 of Ti and the balance of Fe and unavoidable impurities; a round steel ingot with piece weight of 80 tons is produced by electric arc furnace smelting and casting; and the steel ingot is subjected to forging cogging, rolling and a heat treatment process including normalizing, accelerated cooling and tempering to prepare the superlarge thickness chromium molybdenum steel plate with a maximum thickness of 256mm for hydrogenation equipment. A finished steel plate has maximum single weight reaching 60 tons, good cold bending property, no cracking during material manufacture and good resilience. The method provided by the invention reduces labor intensity, saves time and improves the utilization rate of materials.

Owner:WUYANG IRON & STEEL +1

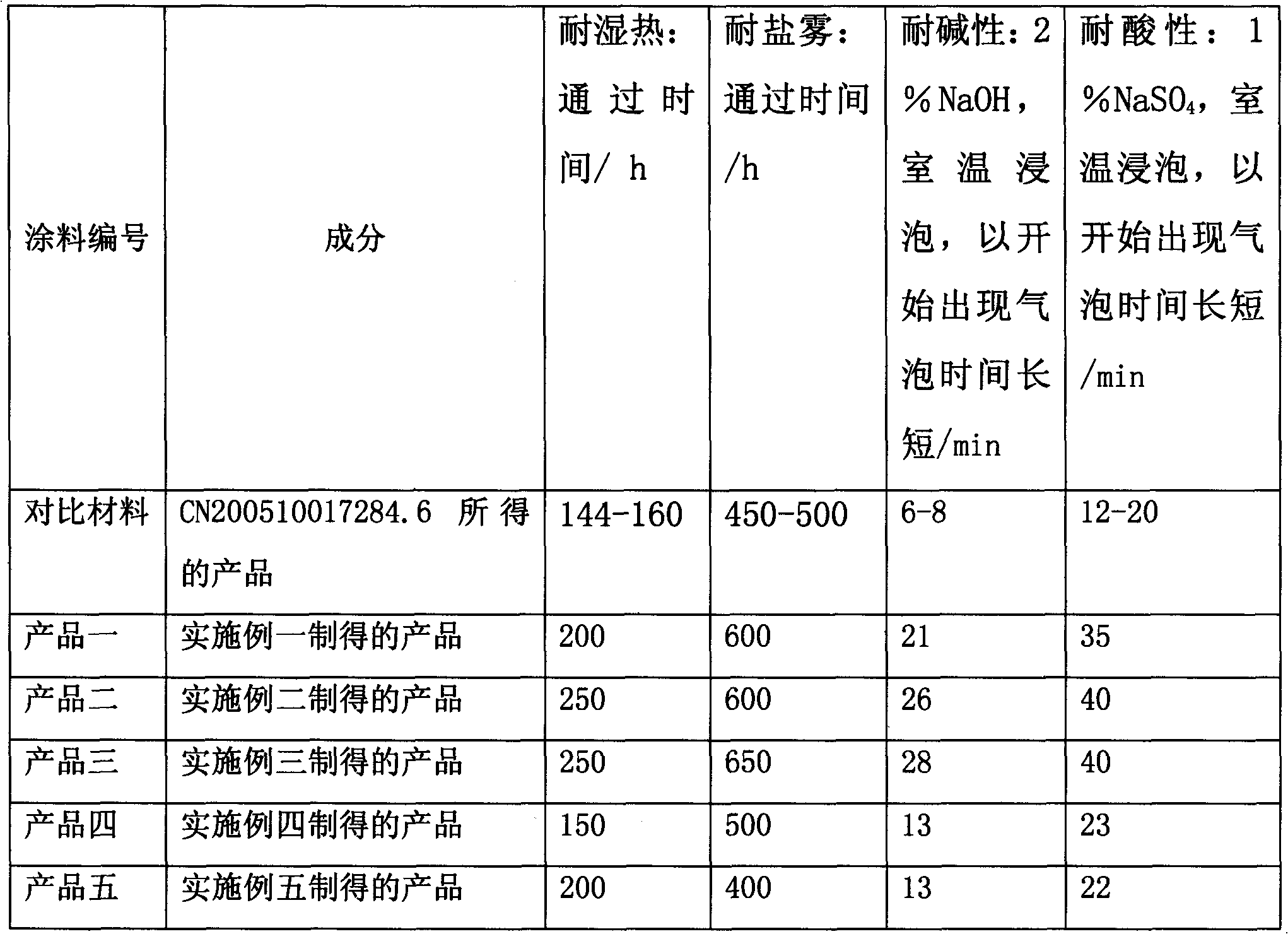

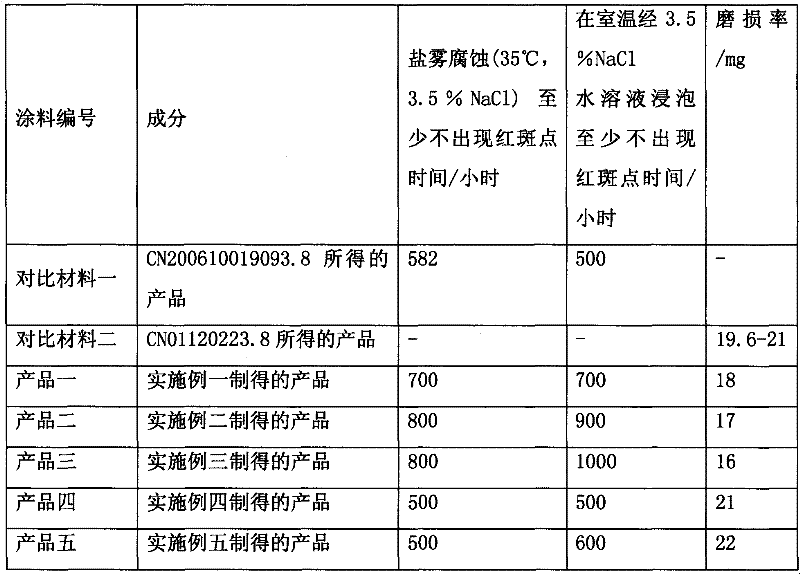

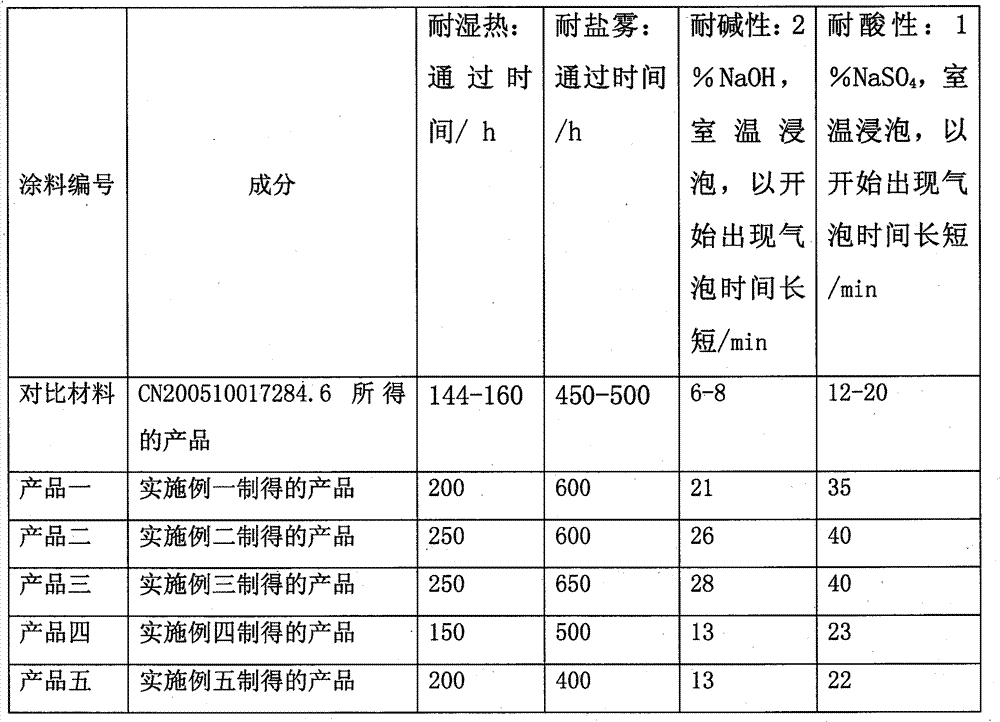

Corrosion resistant coating for metal magnesium and preparation method thereof

InactiveCN101875810ASimple preparation processEasy to operateAnti-corrosive paintsEpoxy resin coatingsEpoxyChemical composition

The invention provides a corrosion resistant coating for metal magnesium and a preparation method thereof. The coating has favorable corrosion resistance. The preparation method has the advantages of simple process and low production cost and is suitable for industrial production. The corrosion resistant coating used for metal magnesium comprises the following chemical compositions in percentage by weight: 40-45wt% of alloy powder, 3-6wt% of titanium carbonitride powder, 3-6wt% of silicon nitride powder, 7-8wt% of butanol and the balance of epoxy resin liquid. The grain sizes of alloy powder,titanium carbonitride powder and silicon nitride powder are 270-800 meshes. The alloy powder comprises the following components in percentage by weight: 2-4wt% of Cu, 0.01-0.1wt% of Sn, 0.2-0.4wt% ofSb, 3-6wt% of Si, 0.03-0.09wt% of Pr and the balance of Ni.

Owner:江苏渝鑫科技股份有限公司

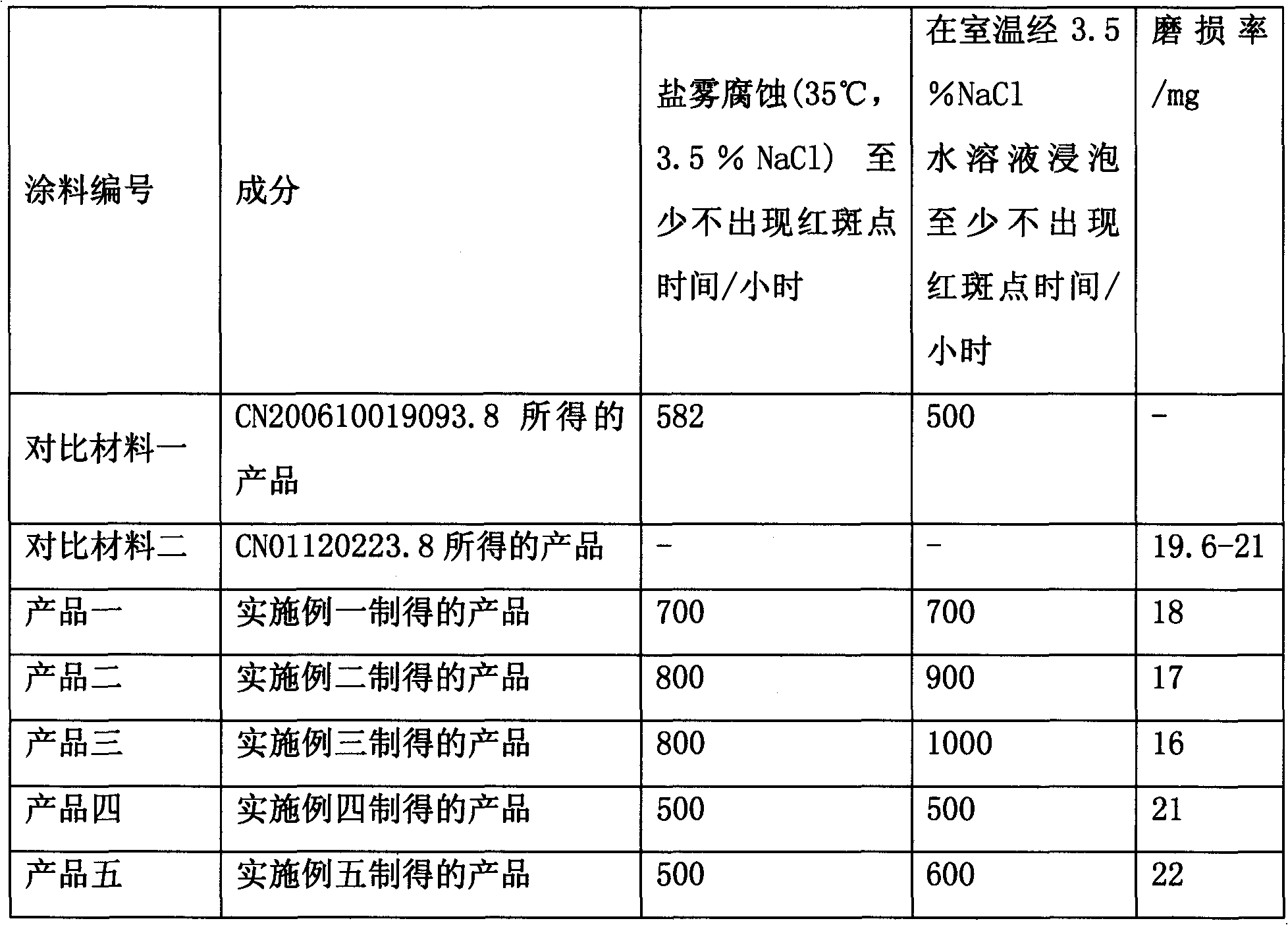

Corrosion resistance coating for steel and preparation method thereof

The invention provides a corrosion resistance coating for steel and a preparation method thereof. The coating has the advantages of excellent performance and good wear resistance. The preparation method has the advantages of simple process and low production cost and is suitable for industrial production. The corrosion resistance coating for steel comprises the following compositions in percentage by weight: 40-45 percent of alloy powder, 3.0-6.0 percent of boron nitride powder, 3-6 percent of silicon carbide powder, 7.0-8.0 percent of butanol powder and the balance of epoxy resin liquid, wherein the particle size of the alloy powder, the particle size of the boron nitride powder and the particle size of the silicon carbide powder are all 270-800 meshes. The alloy powder comprises the following compositions in percentage by weight: 35-40 percent of Zn, 0.01-0.1 percent of Mn, 0.2-0.4 percent of Cd, 0.2-0.4 percent of Sr, 0.02-0.05 percent of Si, 0.03-0.09 percent of Prm 0.05-0.2 percent of Gd and the balance of Al.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

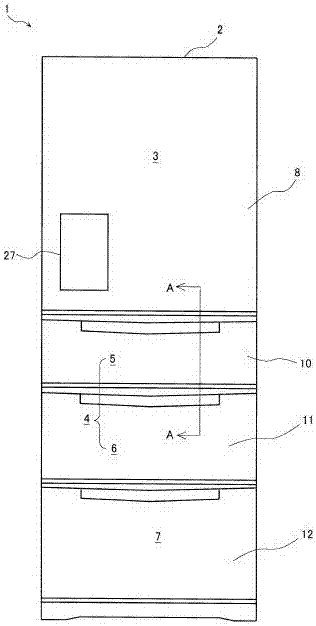

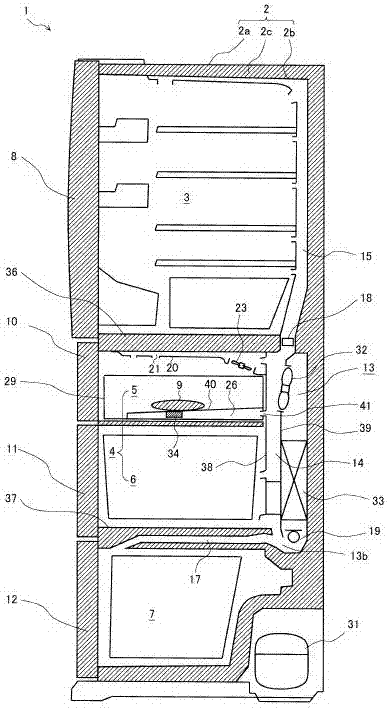

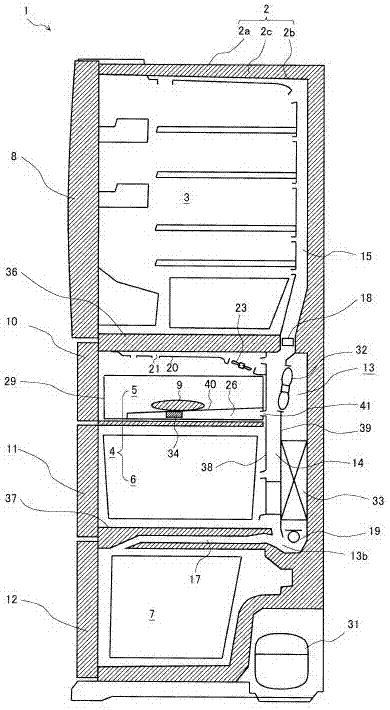

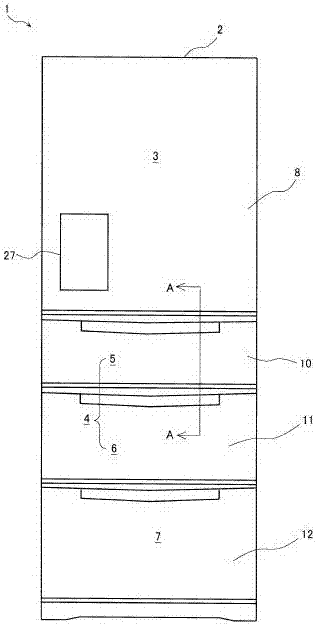

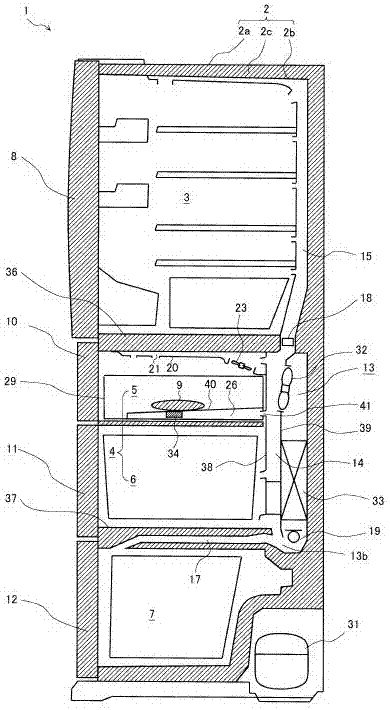

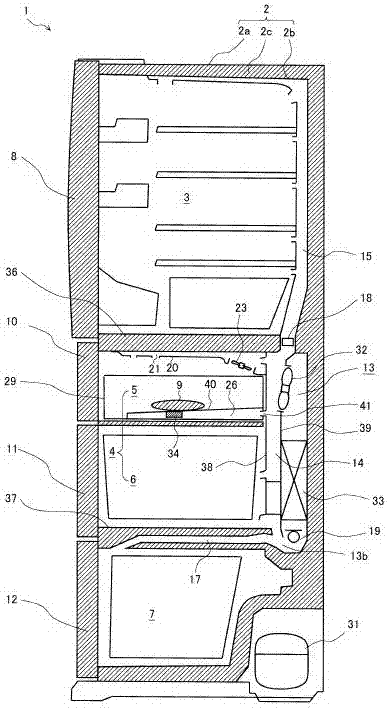

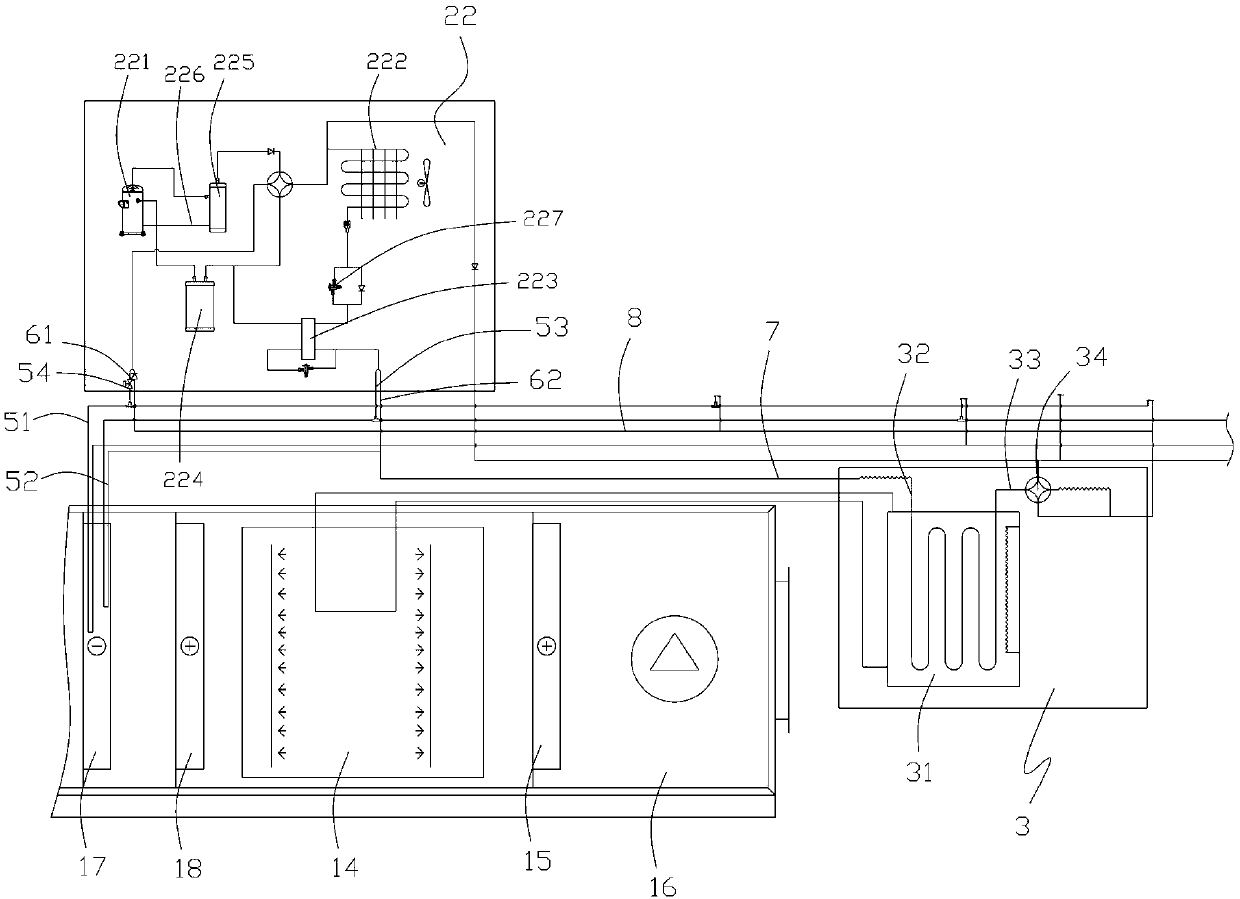

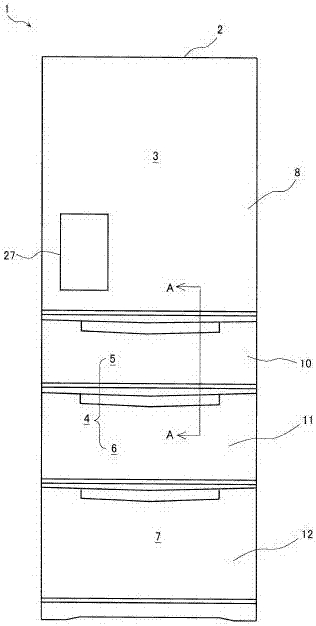

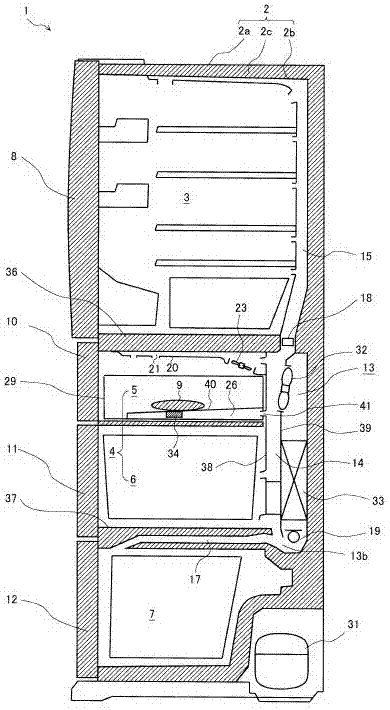

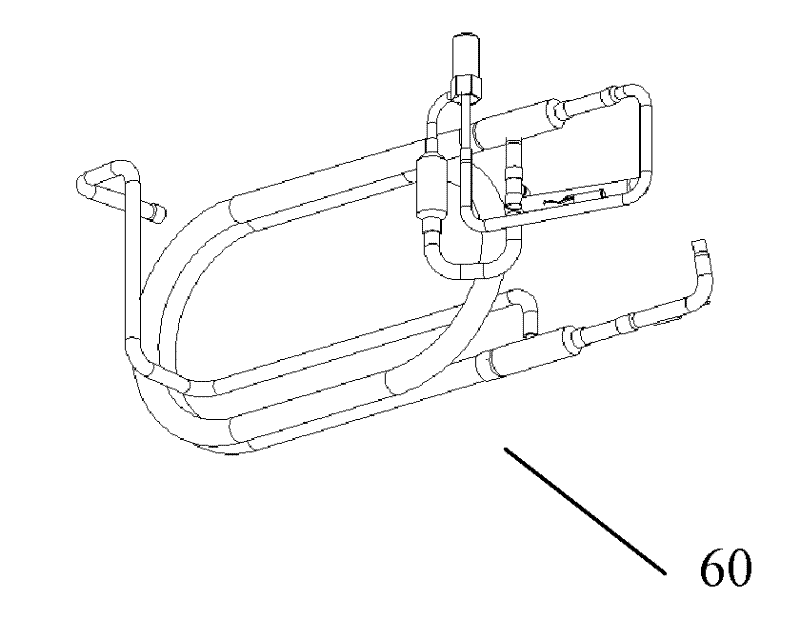

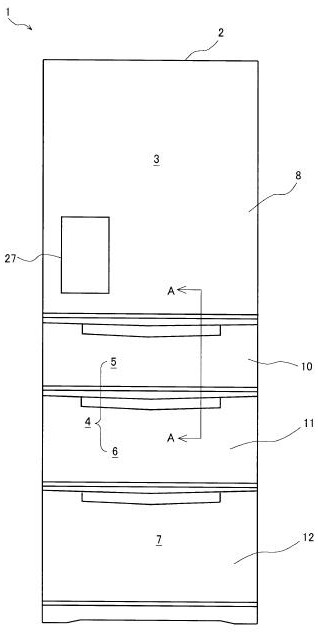

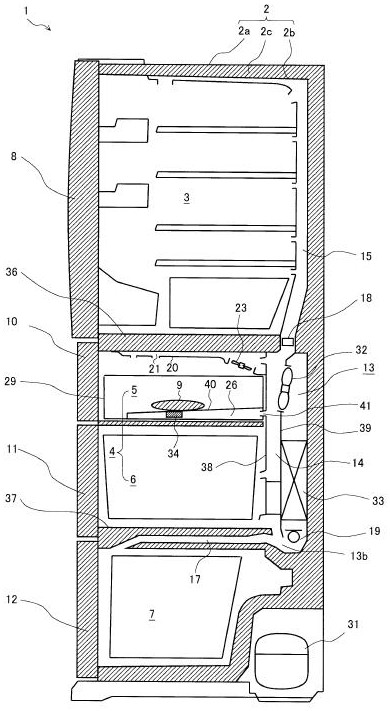

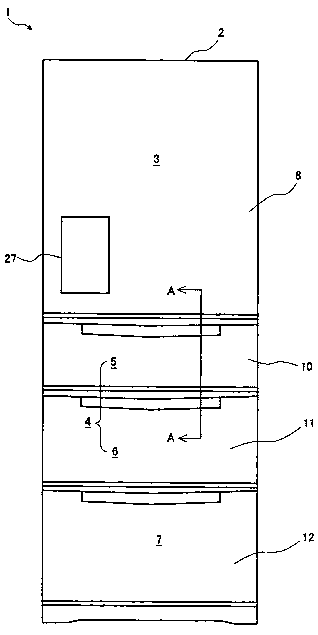

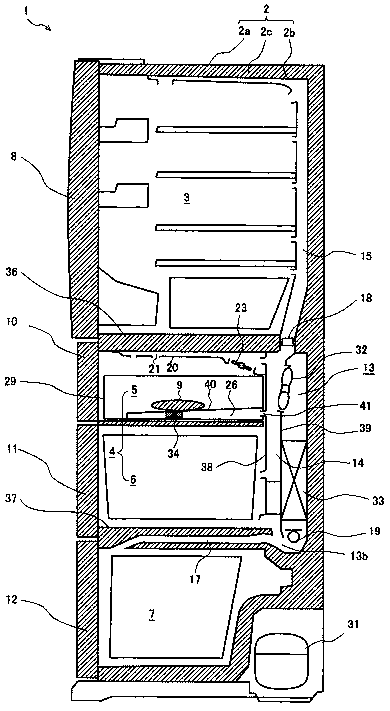

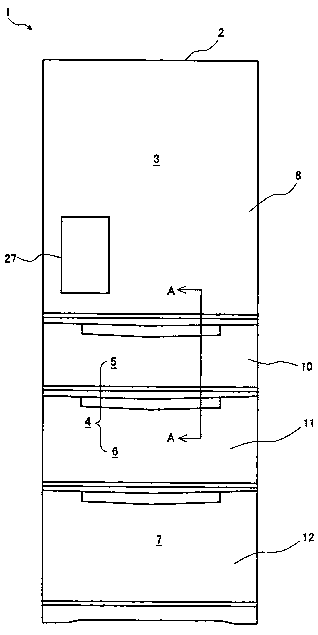

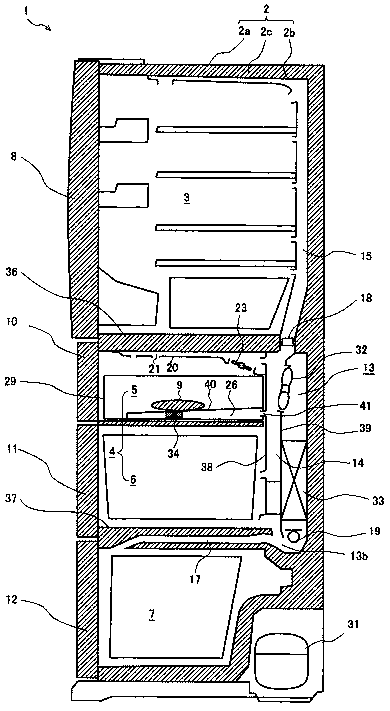

Refrigerating equipment with overcooling function

ActiveCN107062751ACool evenlyImprove supercooling effectLighting and heating apparatusDomestic refrigeratorsCold airWaste management

The invention provides refrigerating equipment with an overcooling function. The refrigerating equipment comprises a refrigerating chamber for containing refrigerated objects, a refrigerating circulating system, a supply air way, a tray, a temperature sensor and air supply machines, wherein the refrigerating circulating system comprises a compressor, a condenser, an expansion mechanism and an evaporator which are connected together, and refrigerating cold air is generated through cooling of the evaporator; the supply air way is used for conveying the cold air generated by the evaporator; the tray is arranged in the refrigerating chamber and used for containing the refrigerated objects, the tray is provided with multiple through holes, an air supply cavity is formed in the bottom of the tray, the air supply cavity is used for receiving the cold air conveyed by the supply air way, and the cold air is exhausted upwardly through the through holes from the bottom of the tray; the temperature sensor is arranged on the refrigerating chamber, located below the tray and used for detecting the bottom temperature of the refrigerated objects on the tray; and the air supply machines are used for blowing the cold air conveyed by the supply air way to the tray below the air supply machines in the refrigerating chamber. By the adoption of the refrigerating equipment with the overcooling function, the refrigerated food is overcooled efficiently, and the overcooling effect is improved.

Owner:QINGDAO HAIER SPECIAL ICEBOX +1

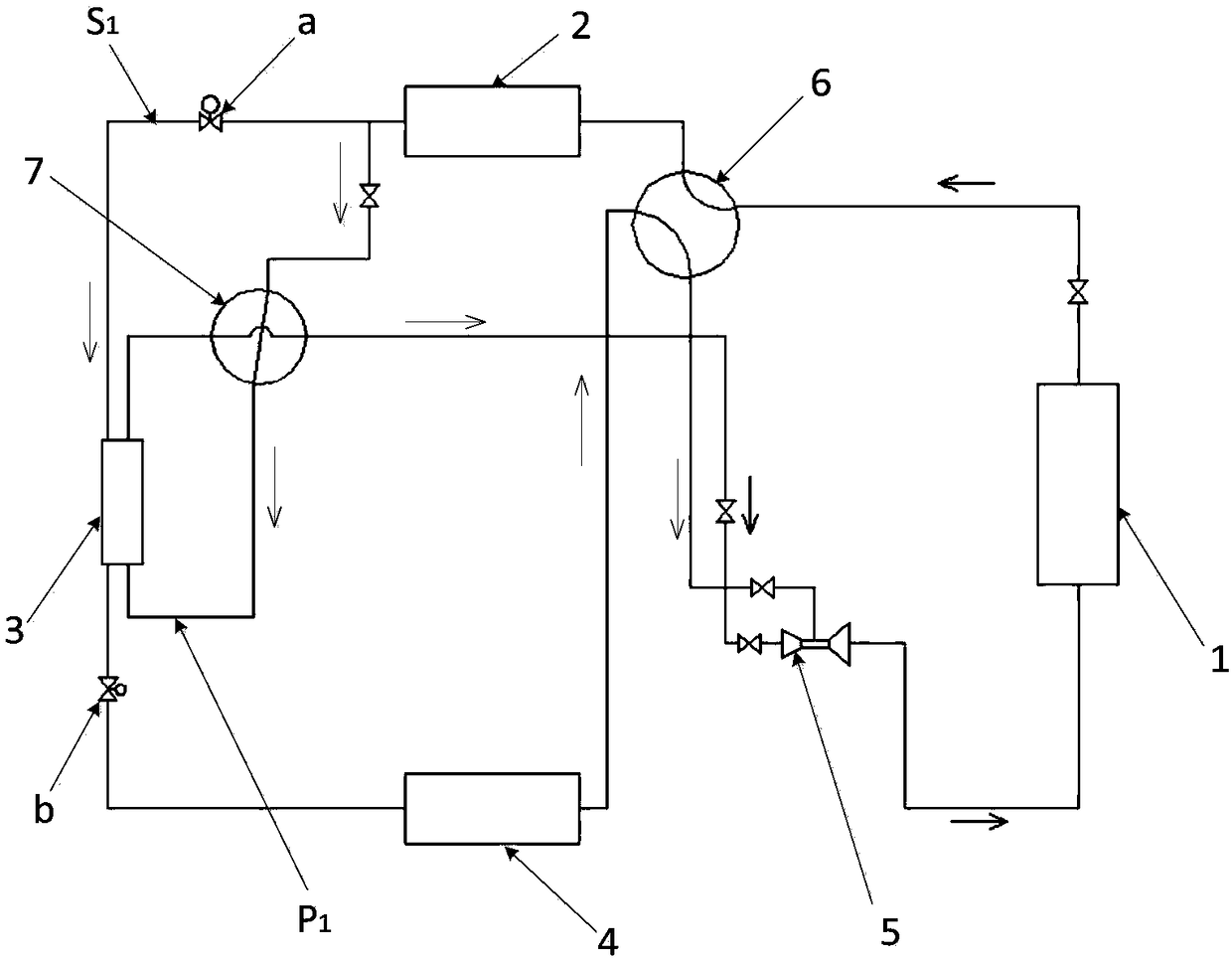

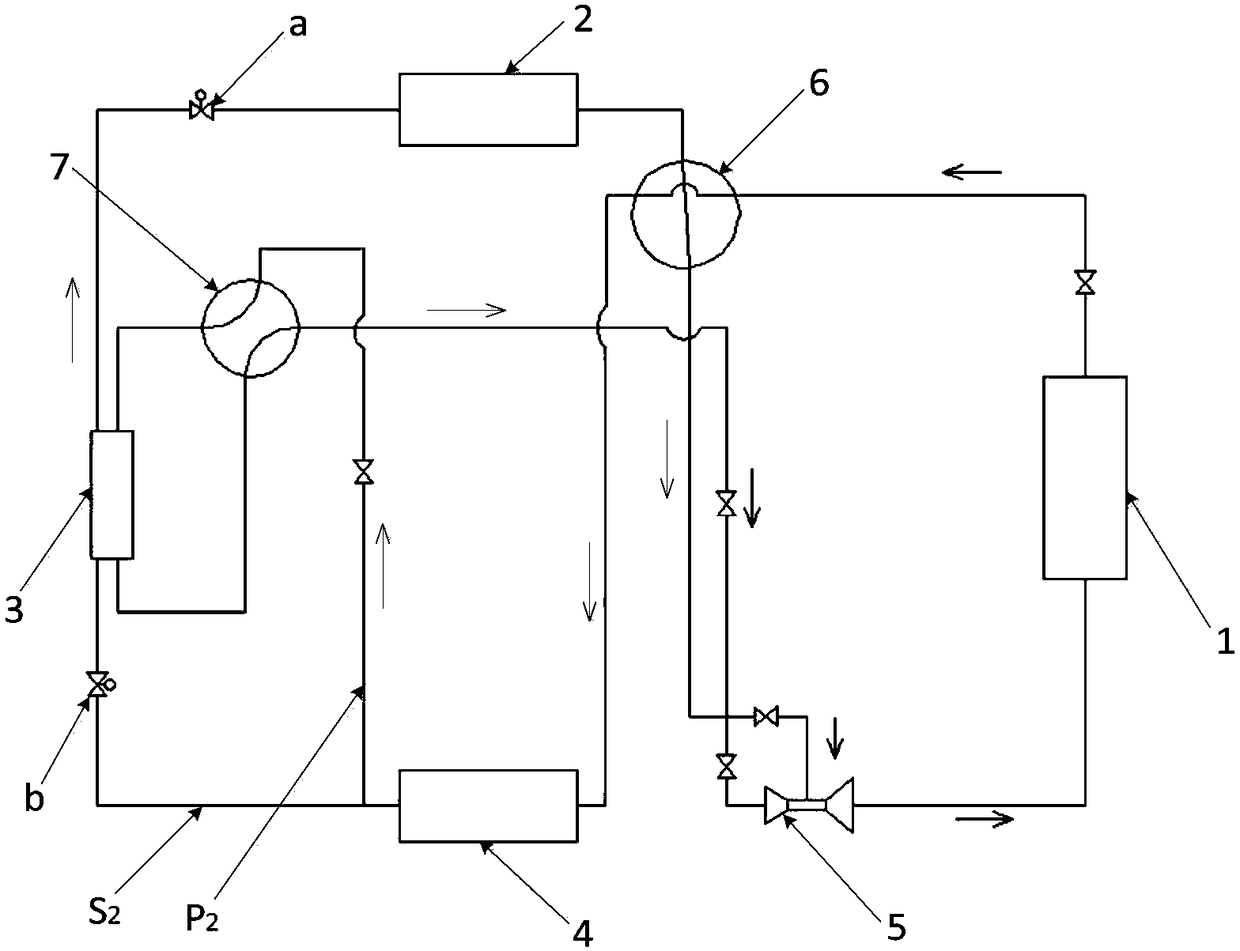

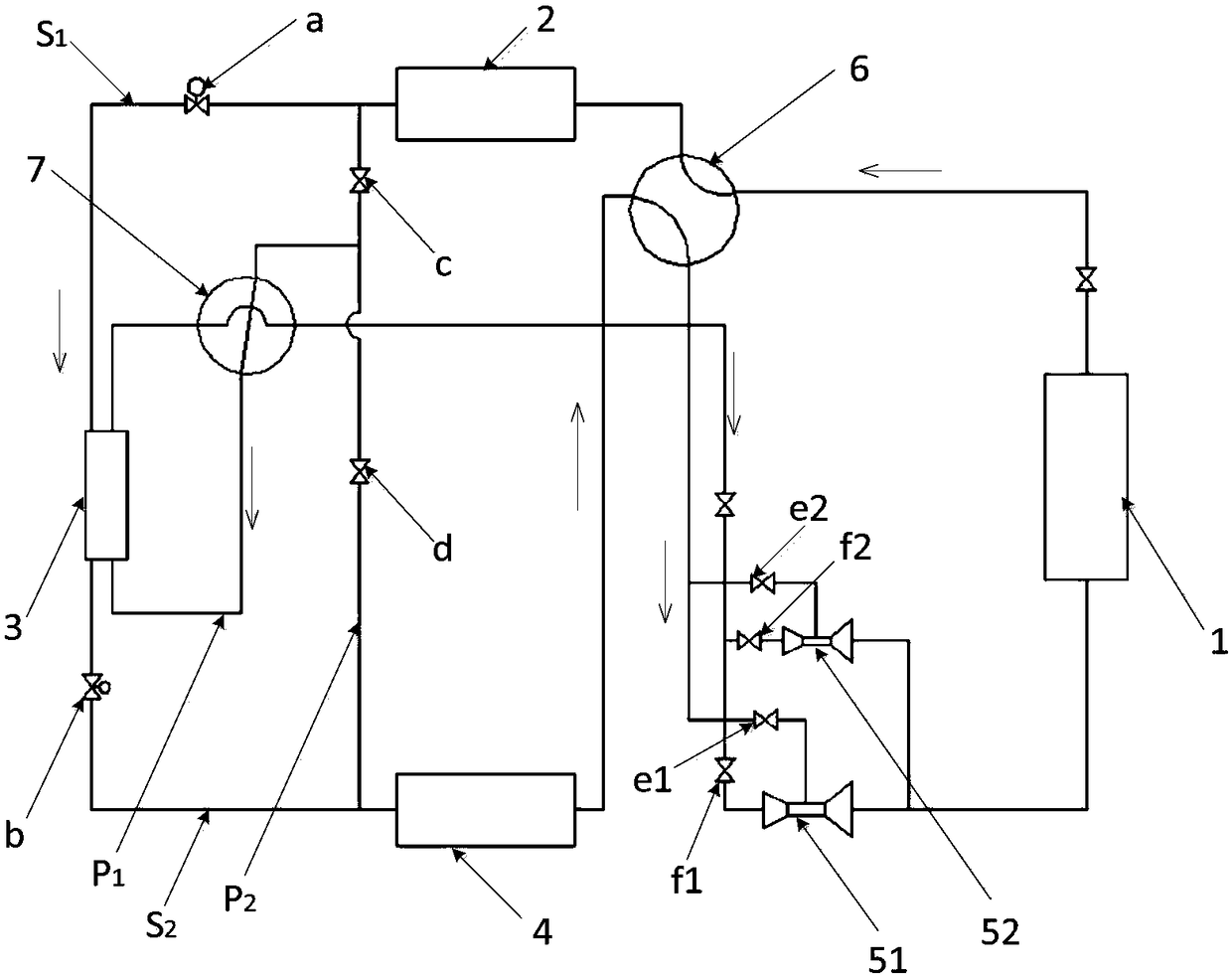

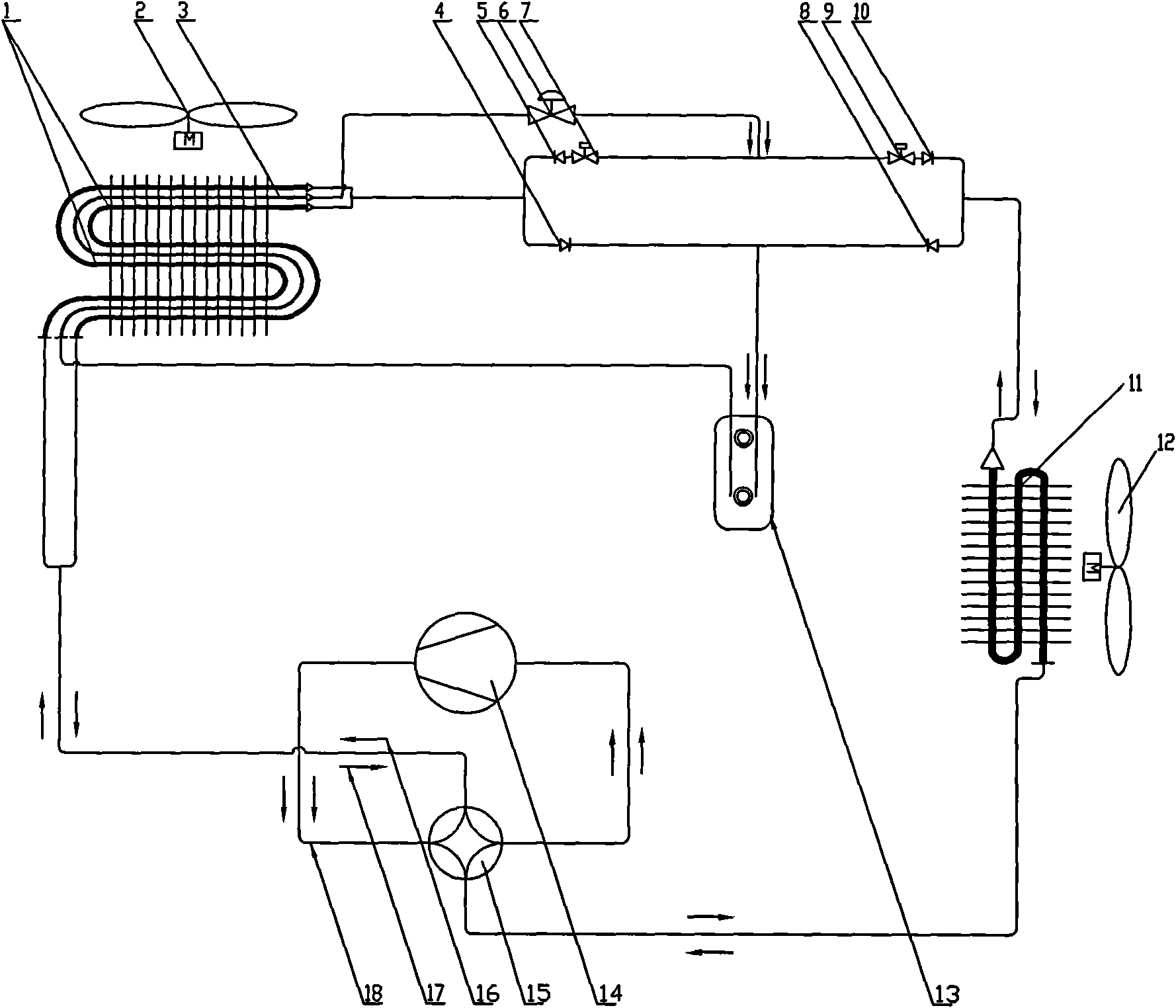

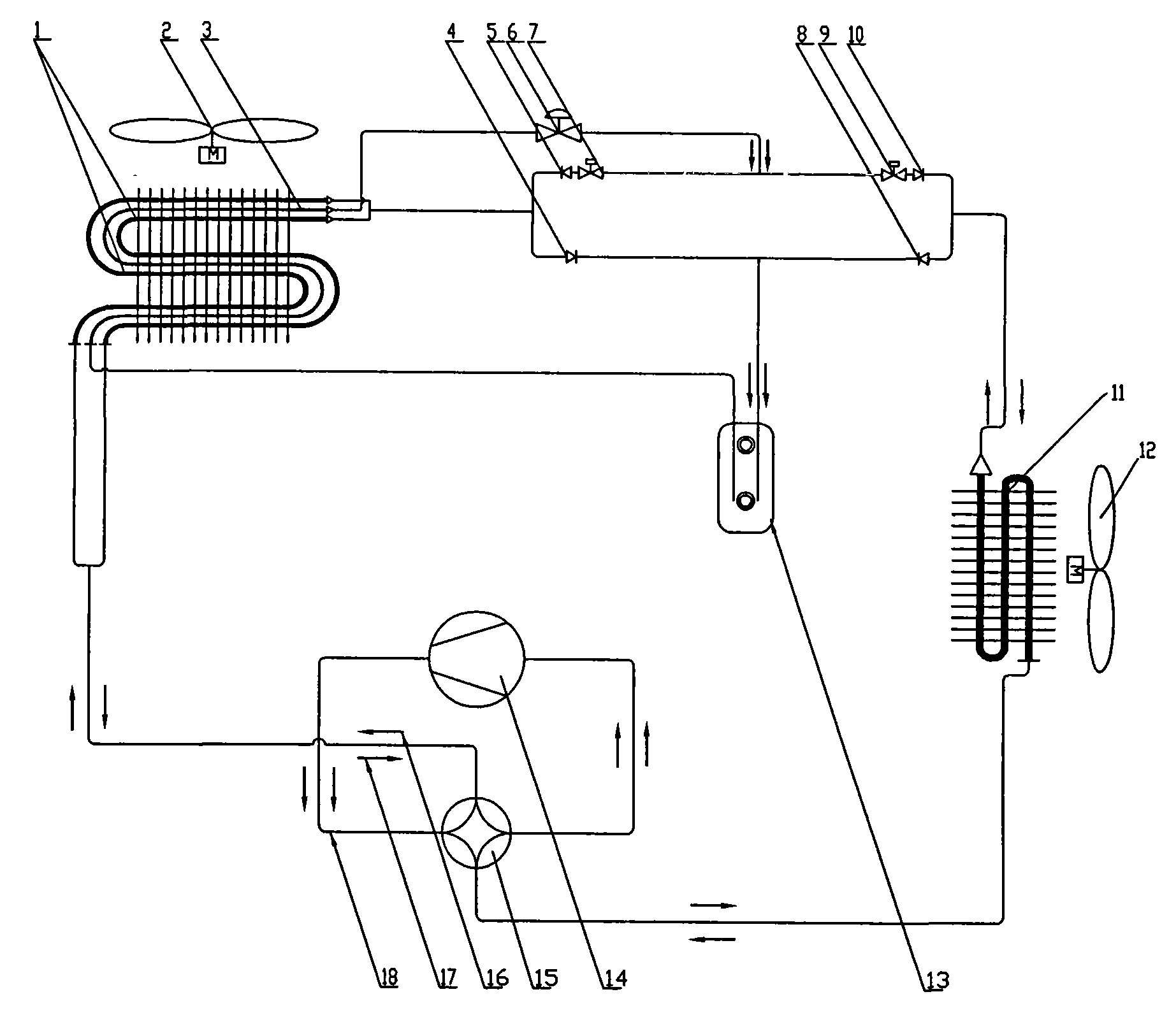

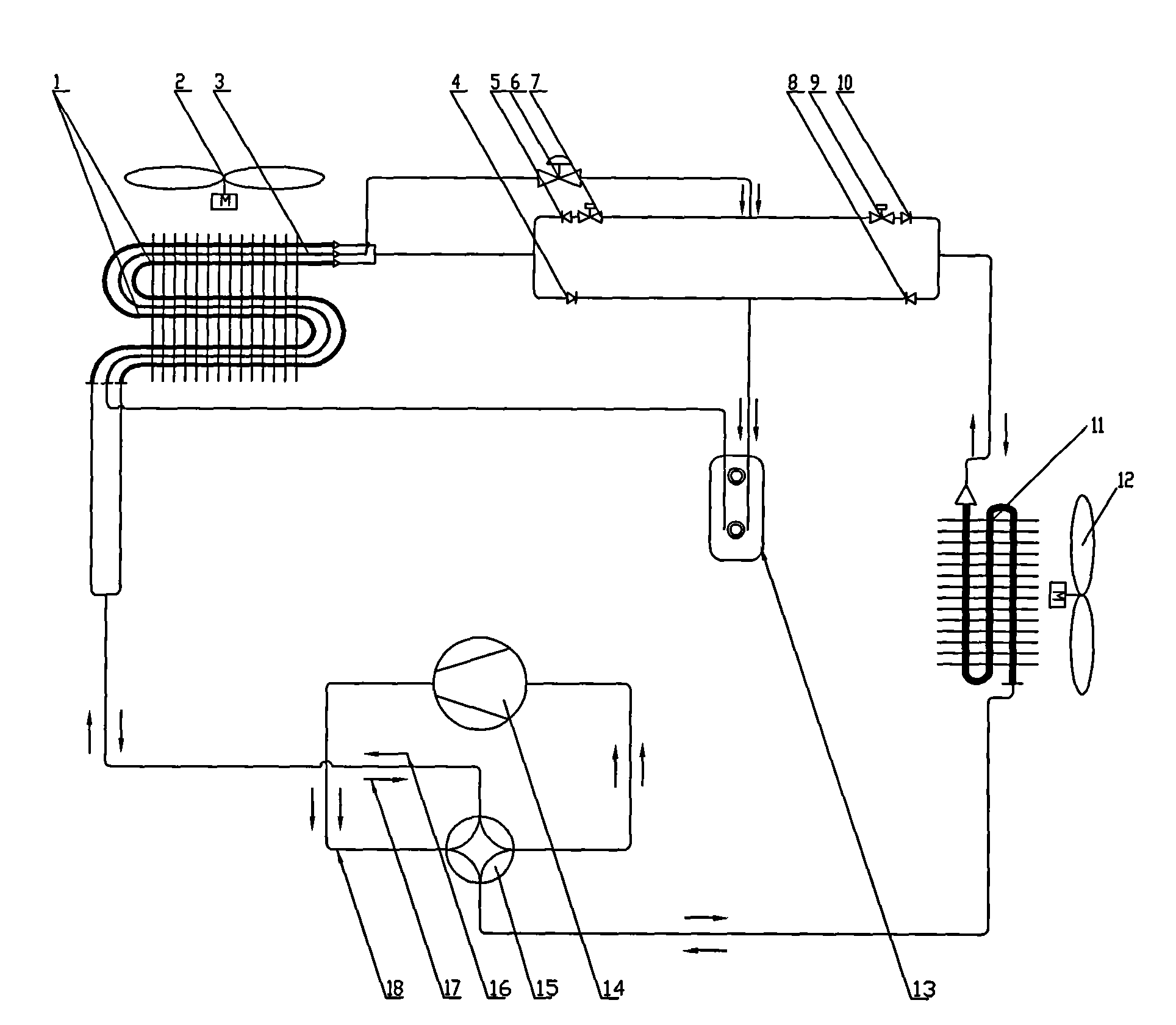

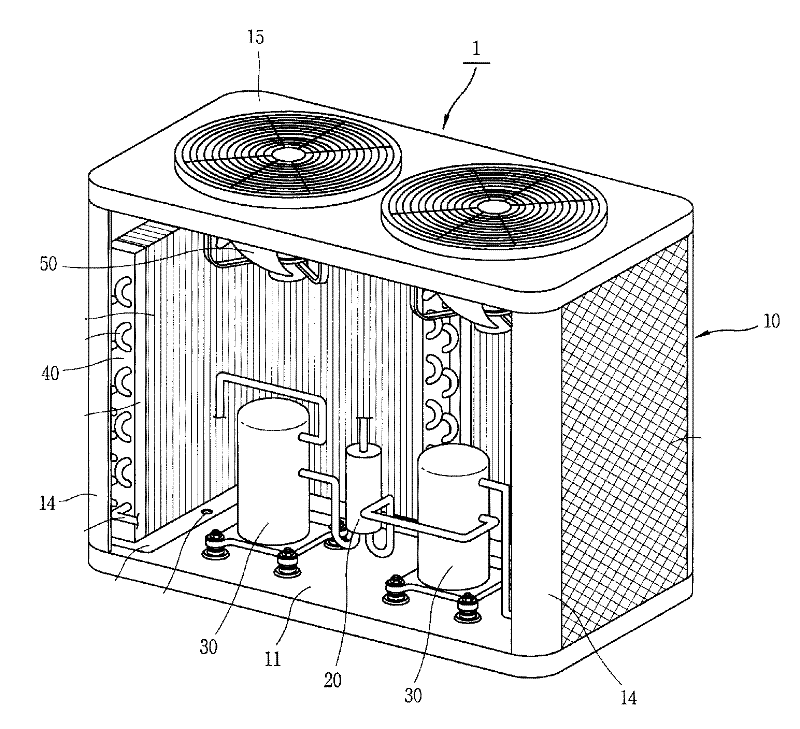

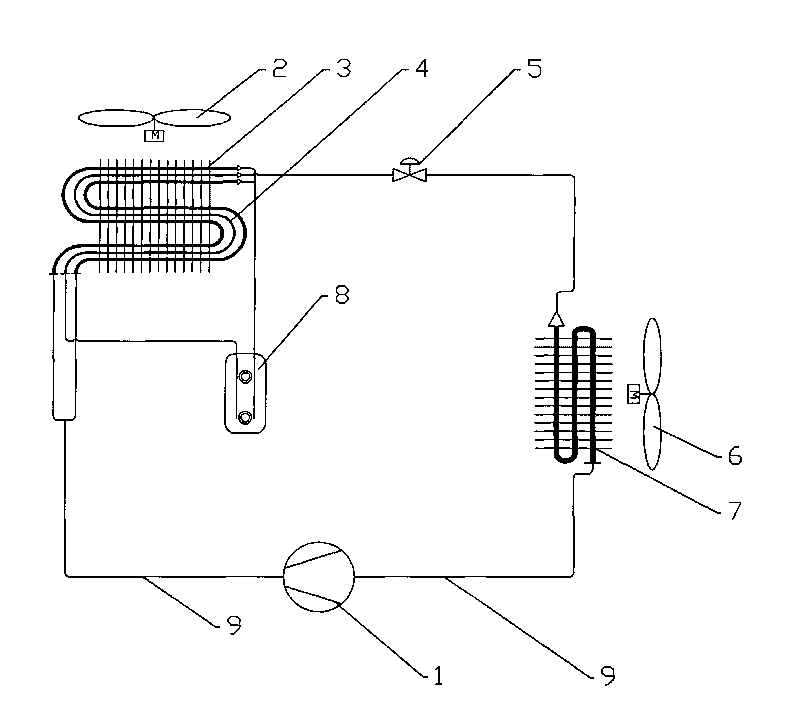

Air conditioning system

InactiveCN108224838AImprove heating effectAchieve energy saving and high efficiencyMechanical apparatusFluid circulation arrangementEngineeringHeating effect

The invention belongs to the technical field of air conditioners and particularly relates to an air conditioning system. In order to effectively improve cooling / heating effect of an air conditioner and reduce energy consumption, the air conditioning system comprises a compressor, an outdoor heat exchanger, an indoor heat exchanger, an auxiliary heat exchanger and an ejector; the compressor, the outdoor heat exchanger, the auxiliary heat exchanger, the indoor heat exchanger and the ejector form a coolant cycle main loop; the compressor, the outdoor heat exchanger / indoor heat exchanger, the auxiliary heat exchanger and the ejector form a coolant cycle branch loop; in cooling / heating cycle, part of a coolant from the compressor flows into the ejector along the main loop, the other part of thecoolant flows into the ejector along the branch loop, and the two parts of the coolant are mixed in the ejector before the mixture reflows into the compressor. The auxiliary heat exchanger is used toimprove the supercooling effect of the coolant; the ejector is used to increase the suction pressure of the compressor, arriving at pressure increasing and efficiency improving; the cooling effect ofthe air conditioner in a high temperature environment and the heating effect thereof in a low temperature environment are improved, and energy consumption is reduced.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD

High-chromium chromium-molybdenum steel plate and production method thereof

The invention discloses a high-chromium chromium-molybdenum steel plate and a production method thereof. The steel plate is composed of the following components in percentage by weight: 0.09%-0.15% of C, 0.5%-0.90% of Si, 0.30%-0.60% of Mn, at most 0.007% of P, at most 0.005% of S, 8.00%-10% of Cr, 0.90%-1.1% of Mo, at most 0.20% of Cu, 0.05%-0.10% of Ni, at most 0.003% of Sb, at most 0.005% of Sn, at most 0.012% of As, and the balance of Fe and inevitable impurities. The production method comprises the following steps: smelting and die casting, heating and rolling, and heat treatment. The high-chromium chromium-molybdenum steel plate satisfies the requirements of high strength, high toughness and high processability for domestic power equipment industry, and can be widely used for manufacturing of domestic power equipment. The steel plate has the advantages of favorable cold bending property, no cracking in the material manufacturing process, and favorable resilience.

Owner:WUYANG IRON & STEEL

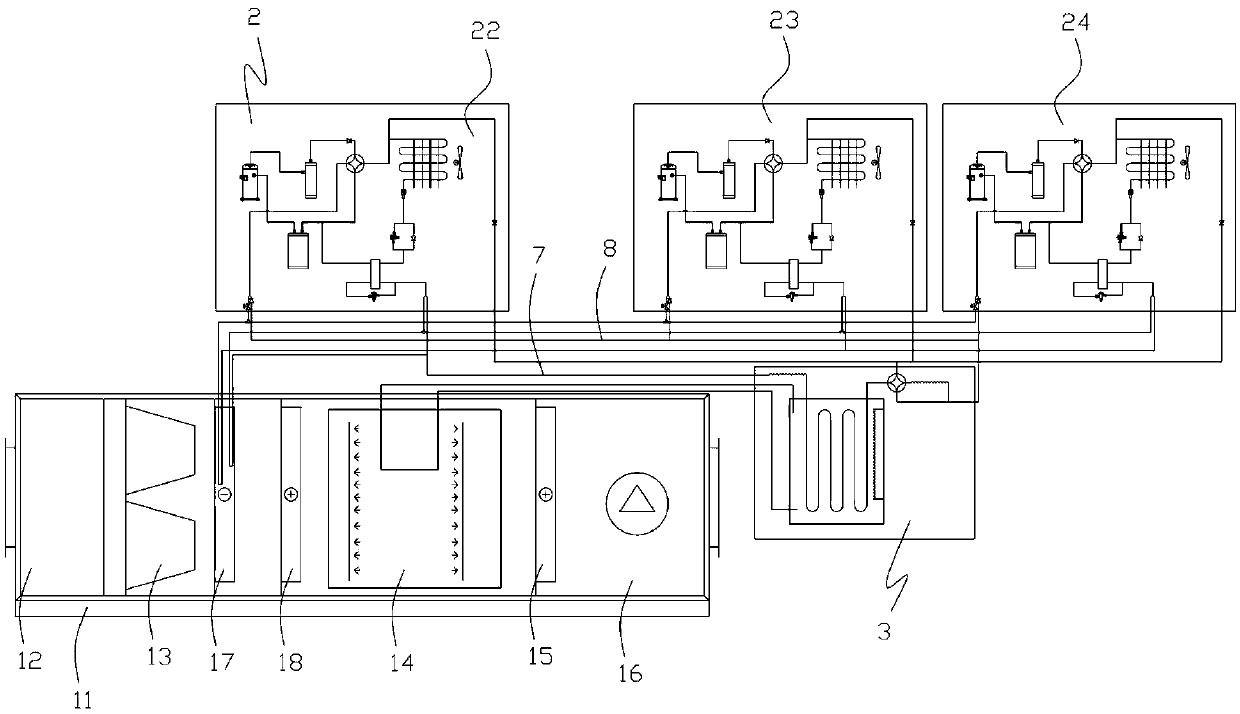

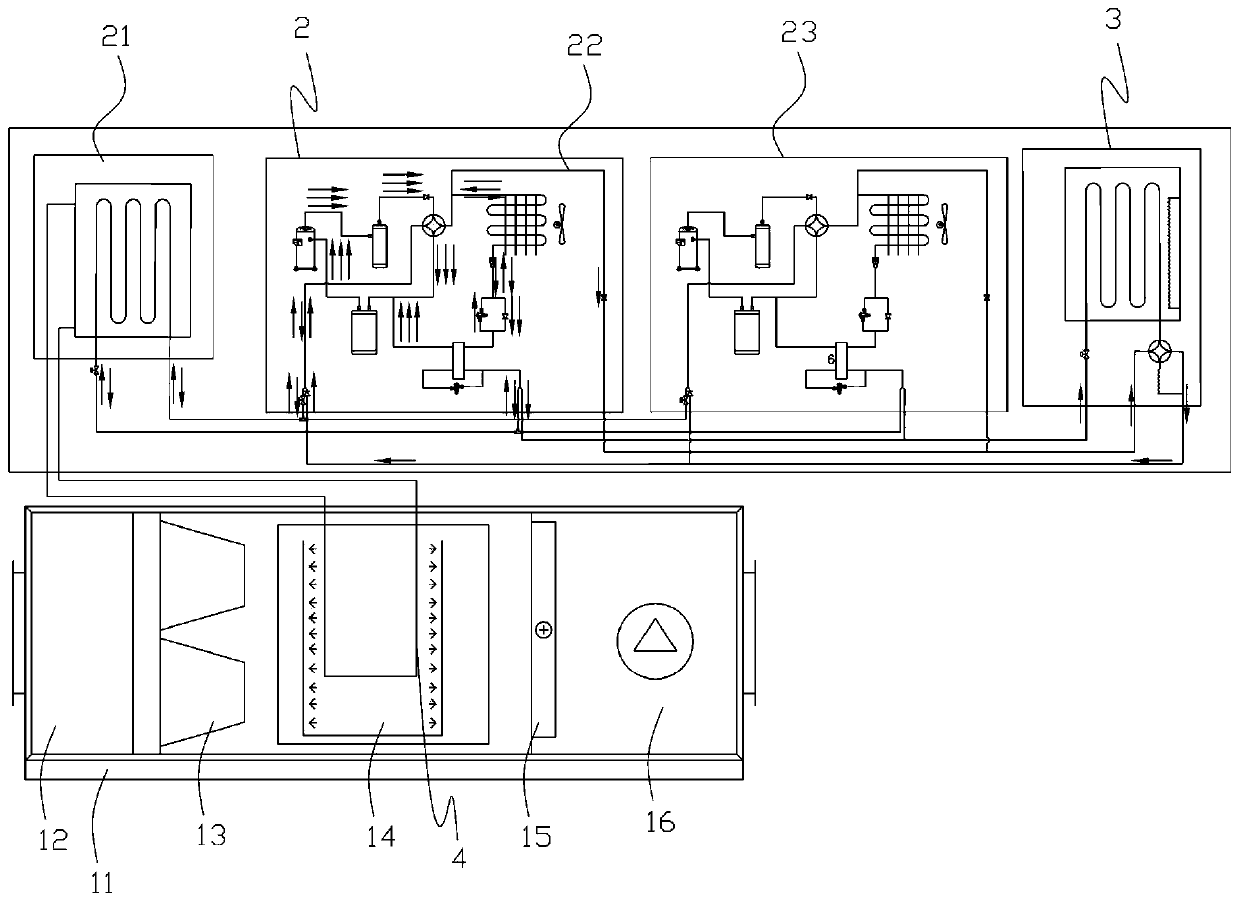

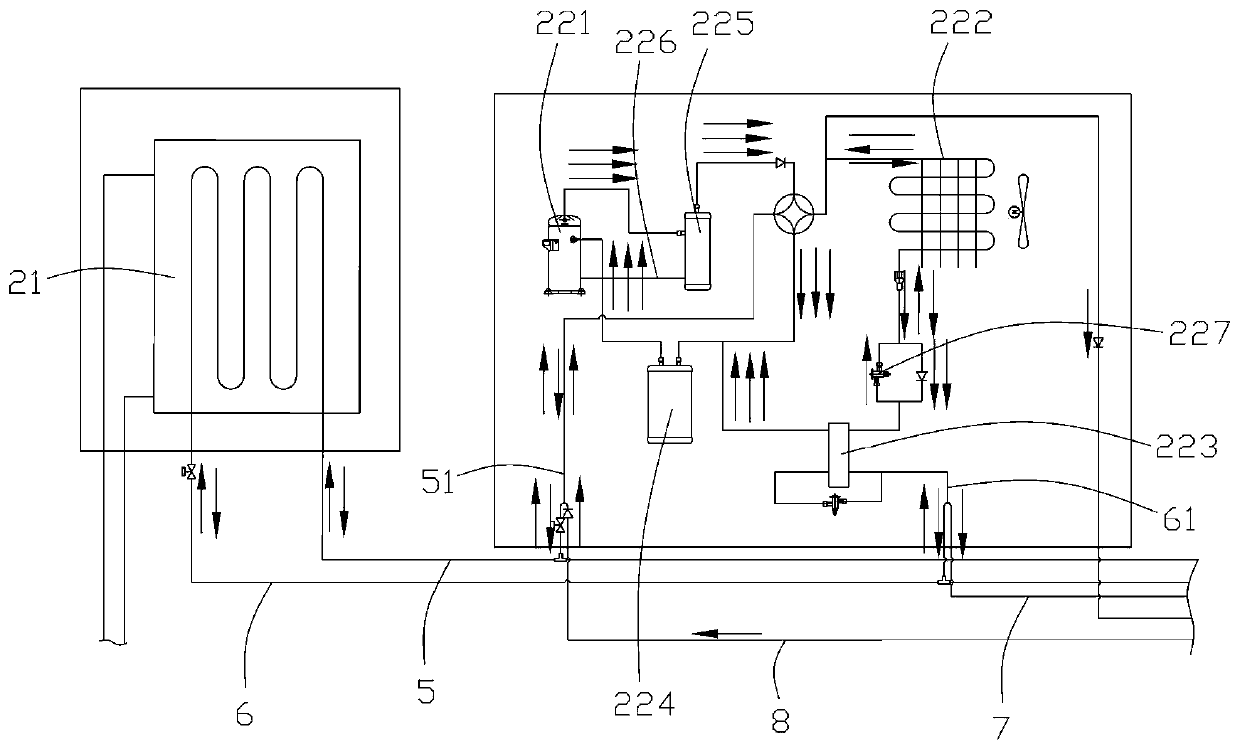

Big supercooling degree completely fresh air air processing machine set

InactiveCN101576297ASolve the problem of subcooling reductionEfficient use ofEvaporators/condensersSubcoolersFresh airProcess engineering

The invention provides a machine set. An outdoor processing unit heat exchanger consists of two parallel condenser tubes; and a supercooler is positioned between the two parallel condenser tubes of the outdoor processing unit heat exchanger. The refrigeration / heat cycle of the machine set is as follows: in a working condition of refrigeration, a refrigerant is condensed and supercooled, and then sent to an indoor air supply unit heat exchanger for heat exchange, and finally returned to a compressor, and the whole refrigeration cycle process is completed; and in the working condition of heating, the refrigerant is sent to the indoor air supply unit heat exchanger for heat exchange through the compressor, enters the supercooler for supercooling, enters the outdoor processing unit heat exchanger, and finally is returned to the compressor, and the whole heating cycle process is completed. Because the refrigerant is supercooled after a reservoir, the problem of lowering the supercooling degree is solved; because the supercooler is positioned between the two parallel condenser tubes of the outdoor processing unit heat exchanger, a strong airflow field formed on the middle part of a fan can be effectively utilized, and the actual supercooling effect of the system can be improved; and because of big suppercooling degree of the system, the operating stability and reliability of an expanding valve are improved, and the refrigerating capacity and the refrigerating energy efficiency of the system are also improved.

Owner:NANJING NORMAL UNIVERSITY +1

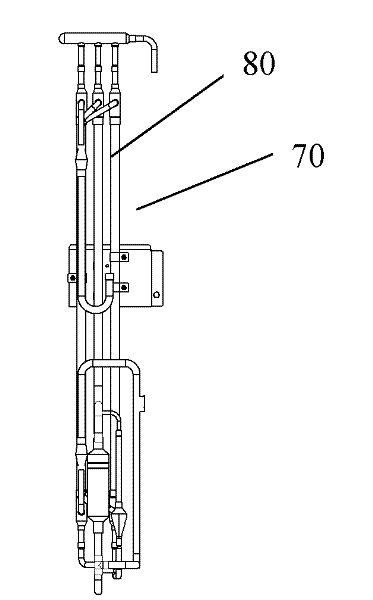

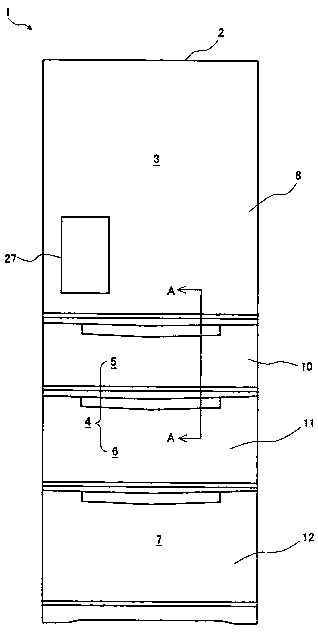

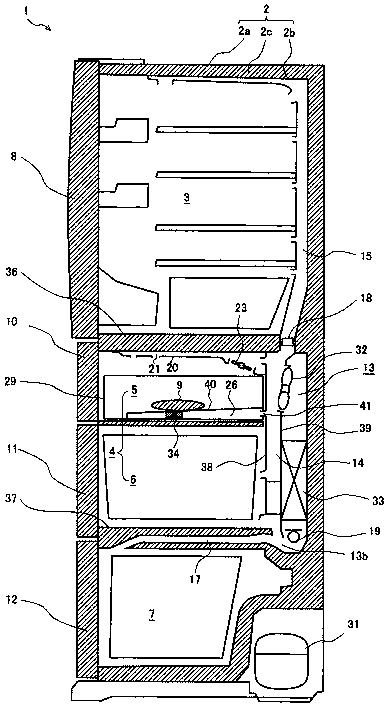

Air cooling type refrigeration equipment

ActiveCN107014129AHigh precisionImprove supercooling effectLighting and heating apparatusDomestic refrigeratorsCold airAir blower

The invention provides air cooling type refrigeration equipment which comprises a freezing chamber, a freezing circulation system, a supply air path, a tray, a temperature sensor and an air blower. The freezing chamber is used for storing frozen food. The freezing circulation system comprises a compressor, a condenser, an expansion mechanism and an evaporator which are connected together, and refrigeration cold air is produced through cooling of the evaporator. The supply air path is used for conveying cold air produced by the evaporator. The tray is used for being fixed inside the freezing chamber and bearing the frozen food. The tray is provided with multiple through holes. The temperature sensor is used for being arranged at the bottom of the tray and detecting the bottom temperature of the frozen food. The air blower is used for blowing cold air conveyed by the supply air path towards the tray at the lower portion inside the freezing chamber. Food is efficiently frozen through supercooling, and therefore the supercooling effect is improved.

Owner:QINGDAO HAIER SPECIAL ICEBOX +1

Big supercooling degree completely fresh air air processing machine set

InactiveCN101576297BSolve the problem of subcooling reductionEfficient use ofEvaporators/condensersSubcoolersFresh airProcess engineering

The invention provides a machine set. An outdoor processing unit heat exchanger consists of two parallel condenser tubes; and a supercooler is positioned between the two parallel condenser tubes of the outdoor processing unit heat exchanger. The refrigeration / heat cycle of the machine set is as follows: in a working condition of refrigeration, a refrigerant is condensed and supercooled, and then sent to an indoor air supply unit heat exchanger for heat exchange, and finally returned to a compressor, and the whole refrigeration cycle process is completed; and in the working condition of heating, the refrigerant is sent to the indoor air supply unit heat exchanger for heat exchange through the compressor, enters the supercooler for supercooling, enters the outdoor processing unit heat exchanger, and finally is returned to the compressor, and the whole heating cycle process is completed. Because the refrigerant is supercooled after a reservoir, the problem of lowering the supercooling degree is solved; because the supercooler is positioned between the two parallel condenser tubes of the outdoor processing unit heat exchanger, a strong airflow field formed on the middle part of a fan can be effectively utilized, and the actual supercooling effect of the system can be improved; and because of big suppercooling degree of the system, the operating stability and reliability of an expanding valve are improved, and the refrigerating capacity and the refrigerating energy efficiency of the system are also improved.

Owner:NANJING NORMAL UNIVERSITY +1

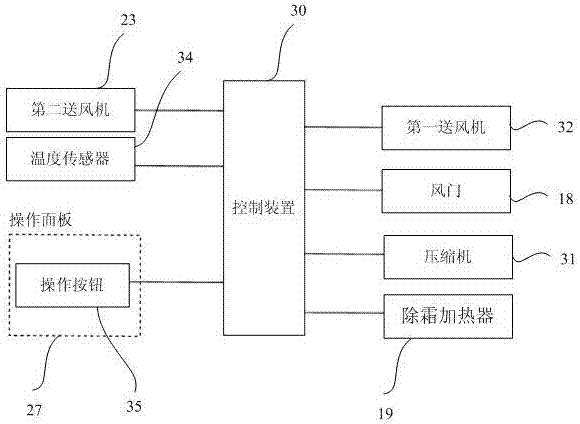

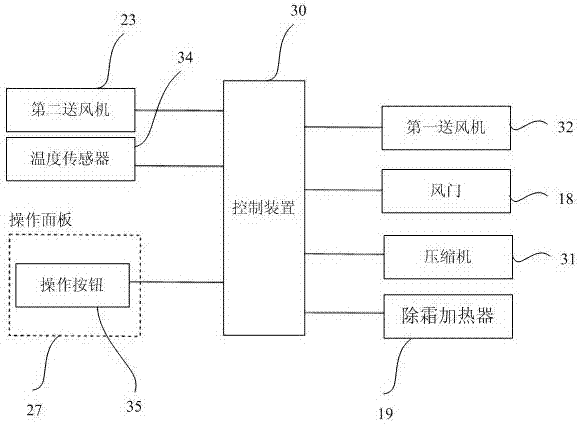

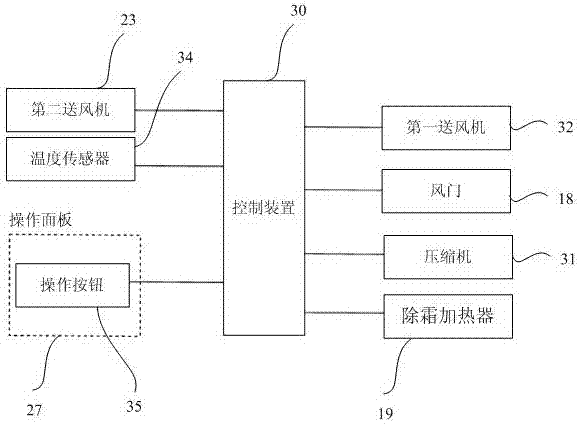

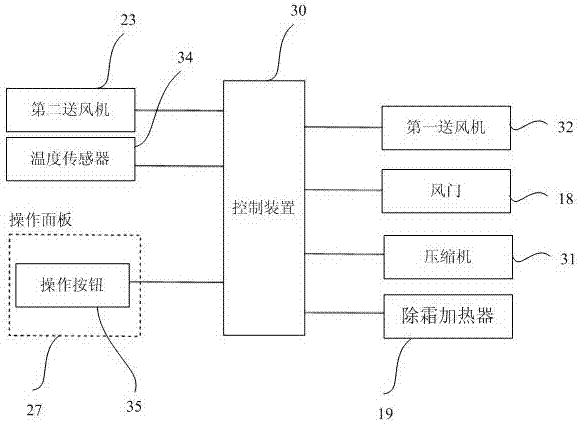

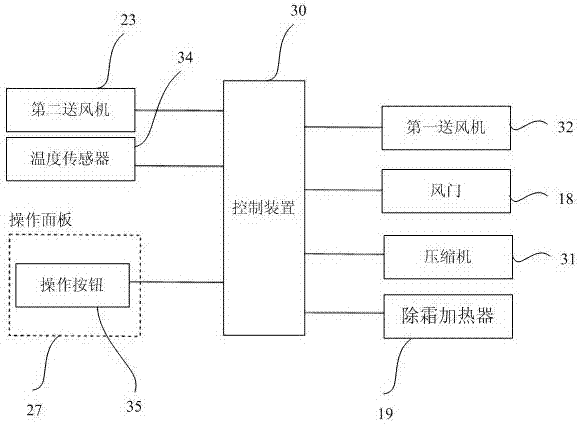

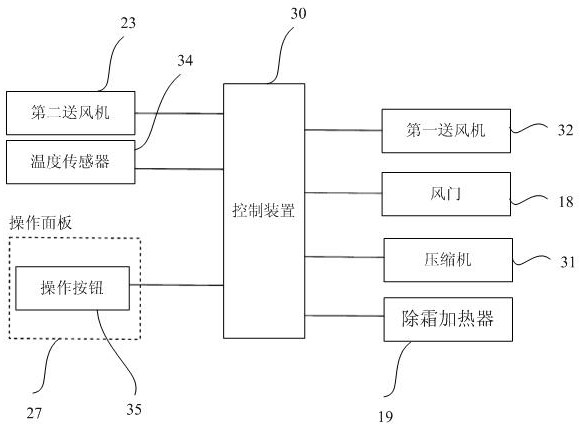

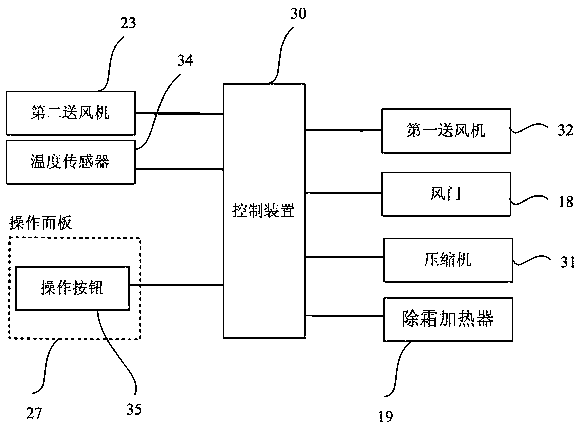

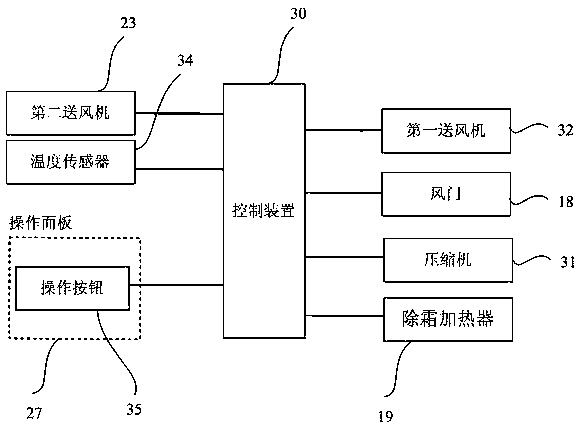

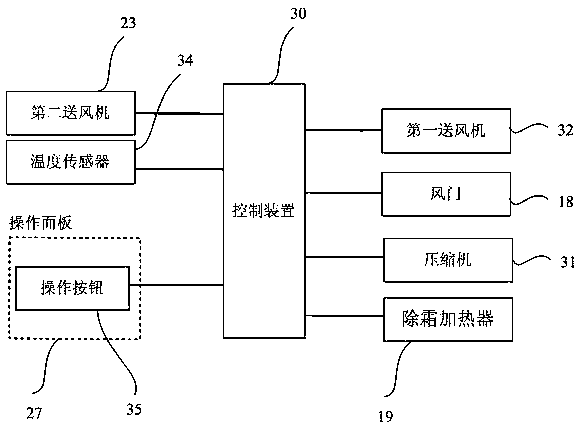

Supercooling control method of refrigerating equipment

ActiveCN106931718AImprove supercooling effectHigh precisionLighting and heating apparatusCooling fluid circulationEngineering

The invention provides a supercooling control method of refrigerating equipment. The supercooling control method comprises the steps that 1, after a supercooling mode is started, a compressor and a first air feeder operate intermittently; 2, when the temperature detected by a temperature sensor is lower than a first set temperature value T1, the compressor and the first air feeder operate continuously; 3, when the temperature detected by the temperature sensor is lower than a second set temperature value T2, the compressor and the first air feeder operate intermittently, and a second air feeder operates continuously; and 4, when the temperature detected by the temperature sensor is lower than a third set temperature value T3, the refrigerating equipment operates according to a conventional refrigerating mode, specifically, T1>T2>T3. Food is frozen efficiently through supercooling so that the supercooling effect can be improved.

Owner:QINGDAO HAIER SPECIAL ICEBOX +1

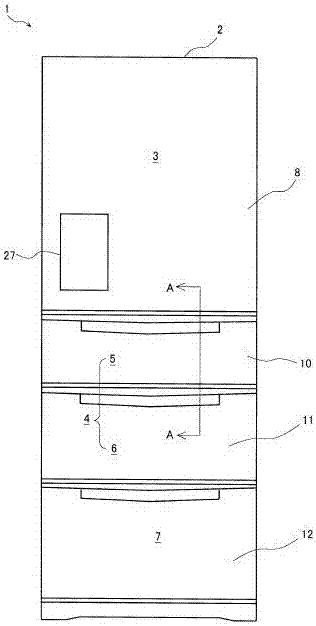

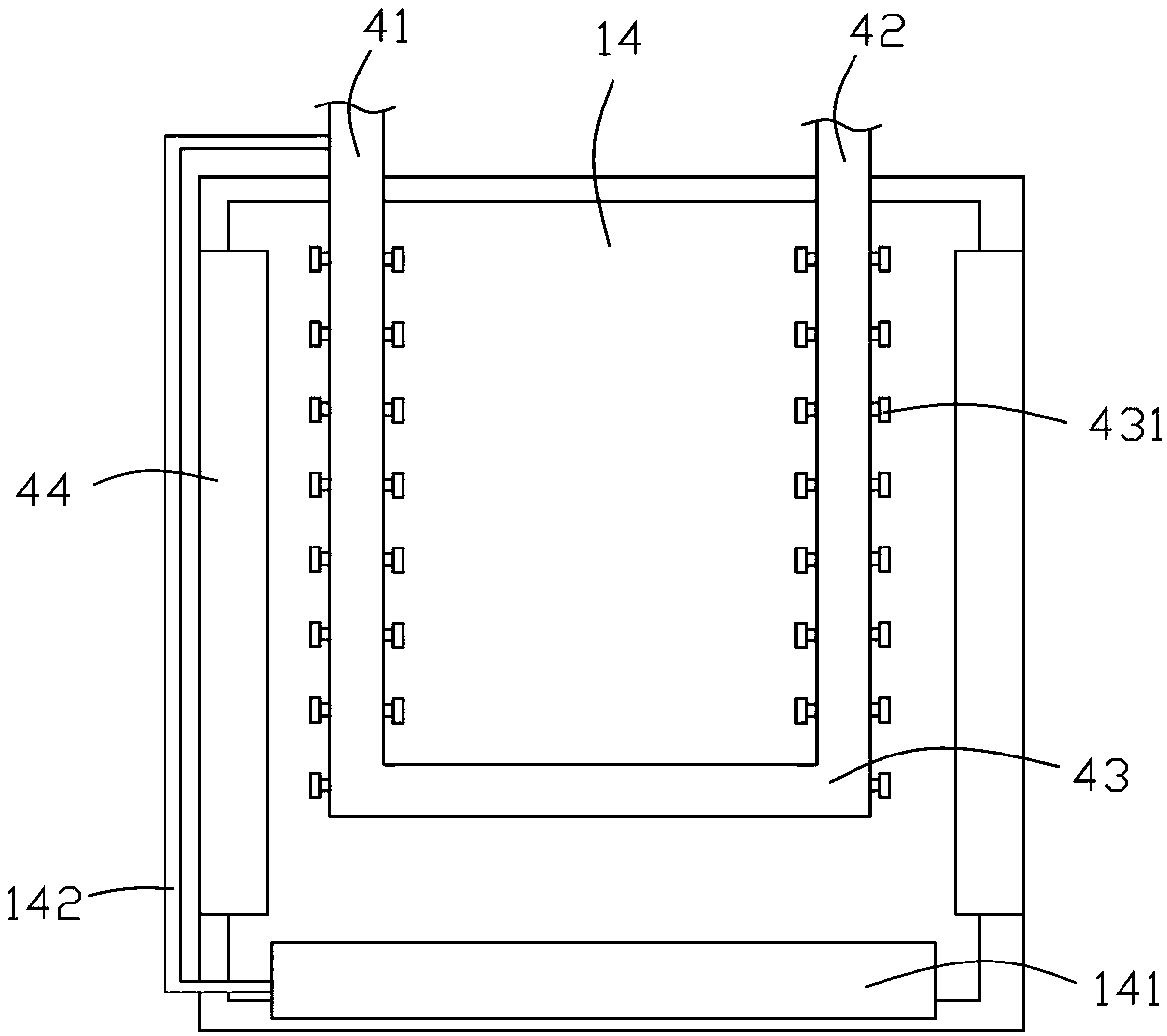

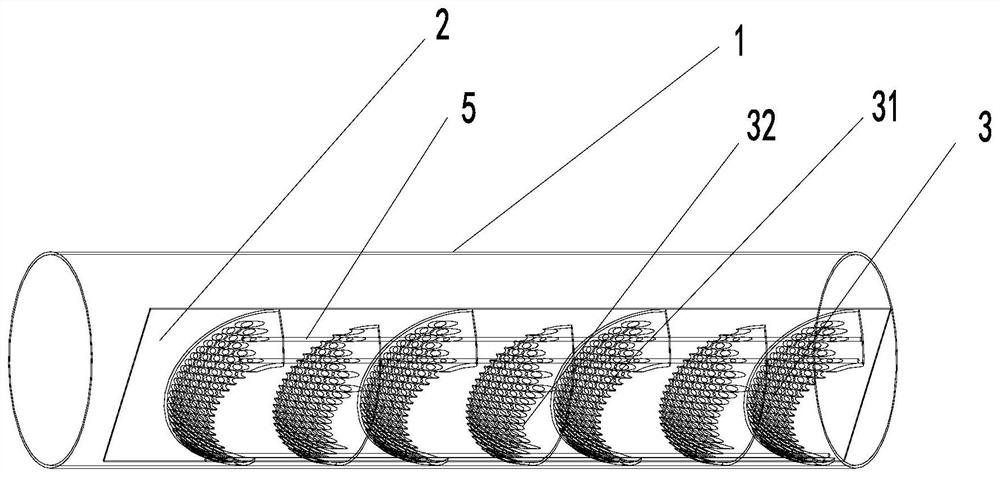

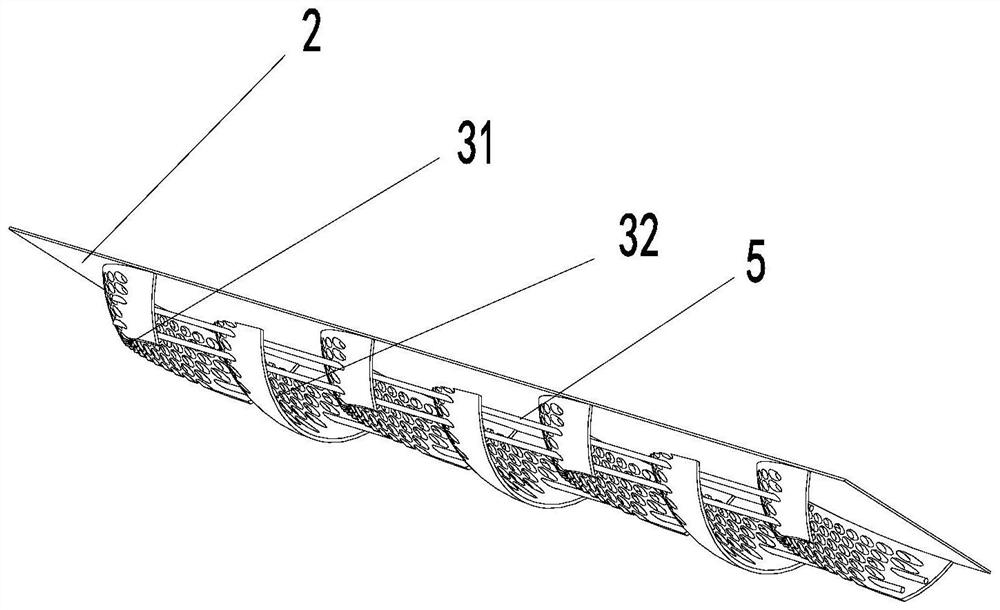

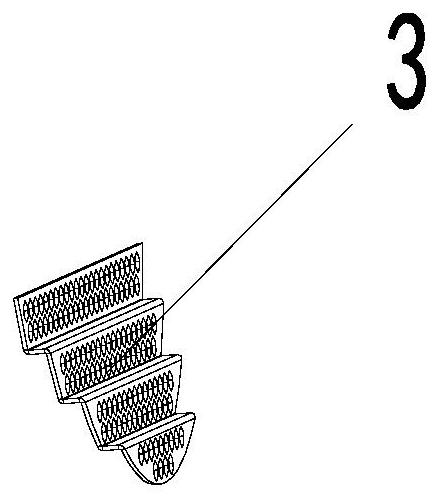

Refrigerating equipment

ActiveCN107036370ACool evenlyEvenly wrappedLighting and heating apparatusDomestic refrigeratorsEngineeringFreezing chamber

The invention provides refrigerating equipment. The refrigerating equipment comprises a freezing chamber used for containing frozen objects, a freezing circulating system comprising a compressor, a condenser, an expansion mechanism and an evaporator which are connected together, an air supply path used for conveying cool air generated by the evaporator, a pallet used for bearing the frozen objects in the freezing chamber and provided with a plurality of through holes, and a blower used for blowing the cool air conveyed by the air supply path towards the pallet on the lower portion in the freezing chamber, wherein the evaporator is used for generating refrigerating cool air through cooling; and an air supply cavity is formed in the bottom of the pallet and used for receiving the cool air conveyed by the air supply path and discharging the cool air through through holes in the bottom of the pallet upwards. Food is frozen effectively through supercooling so that the supercooling effect can be improved.

Owner:QINGDAO HAIER SPECIAL ICEBOX +1

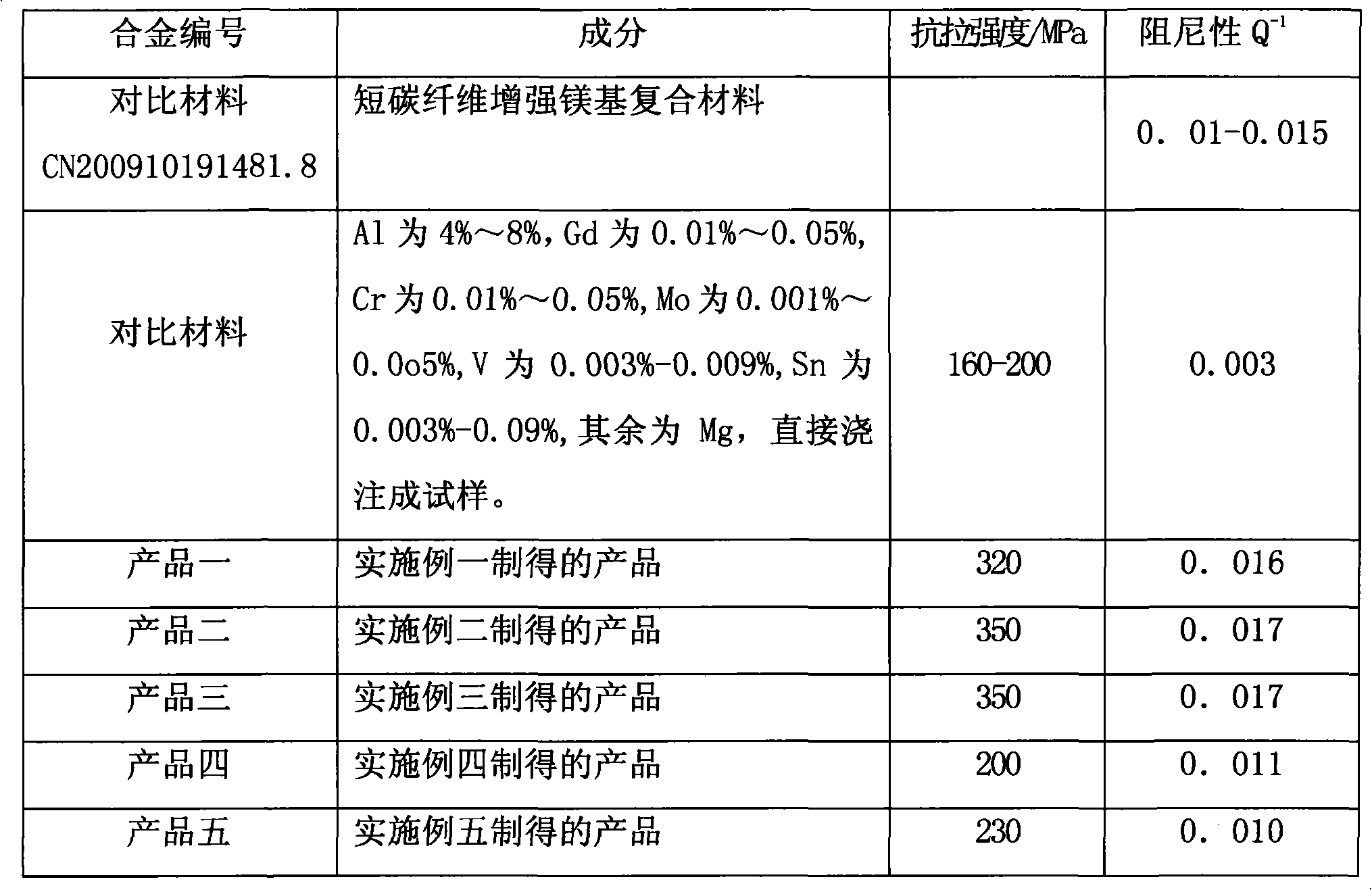

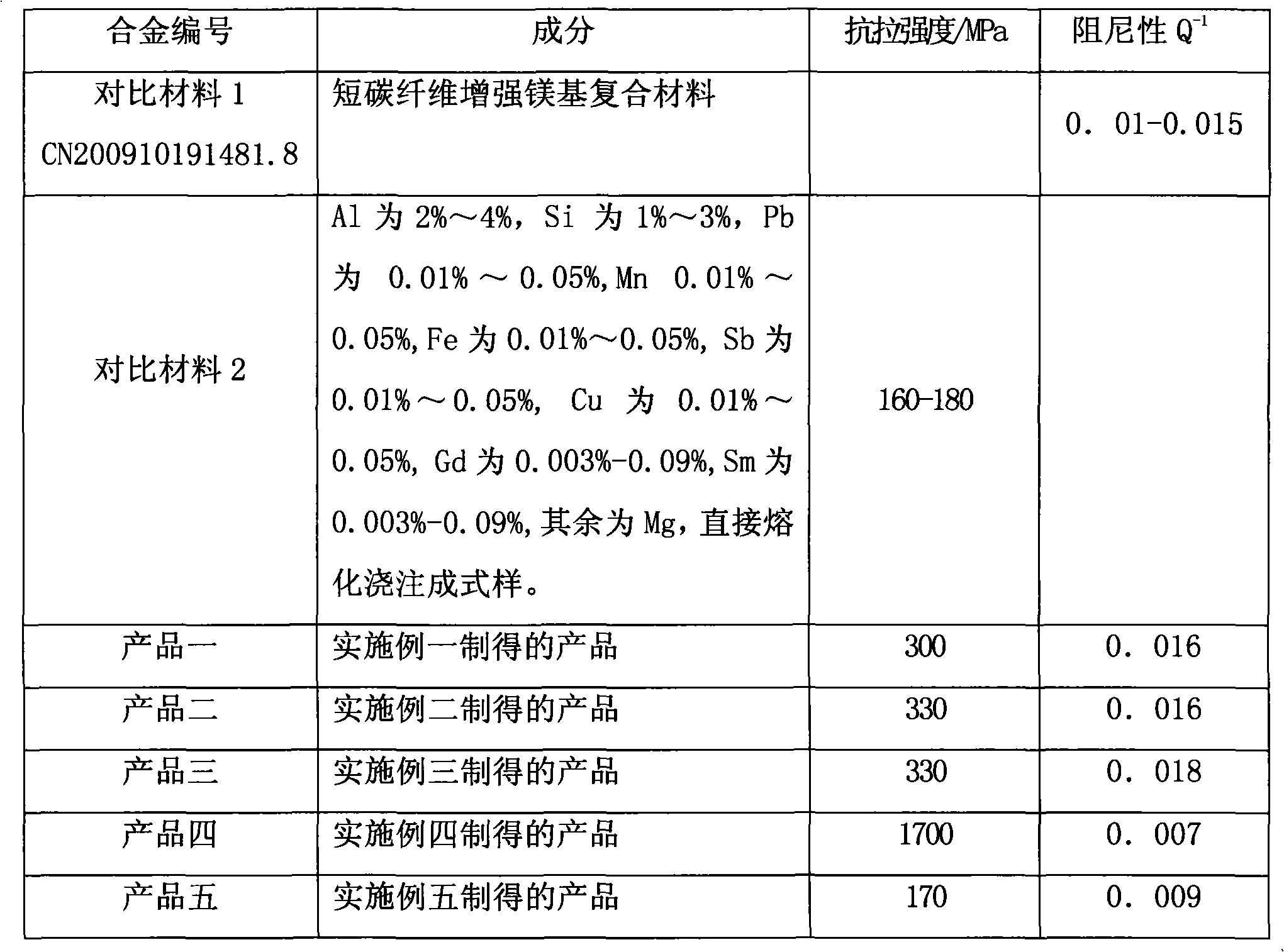

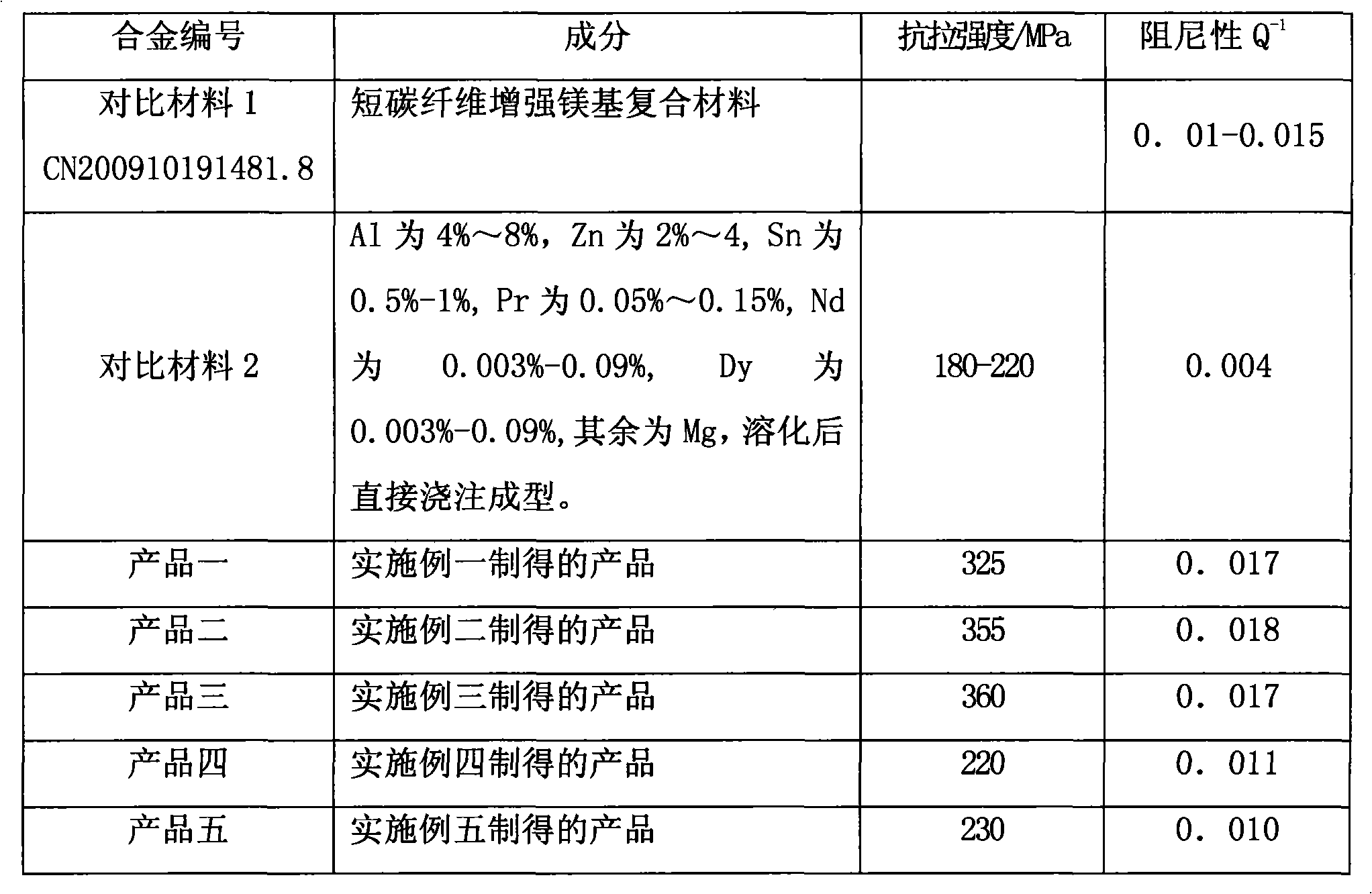

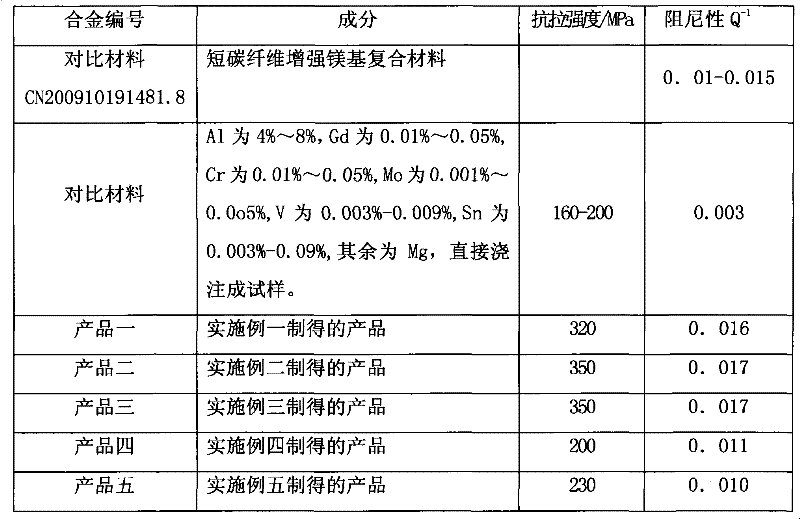

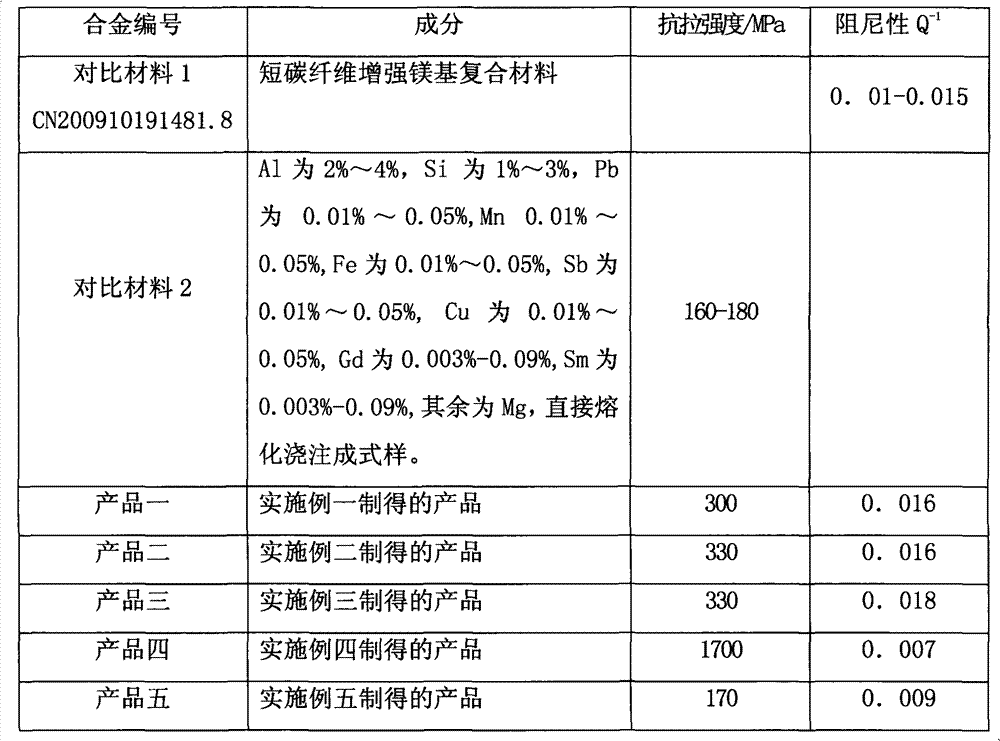

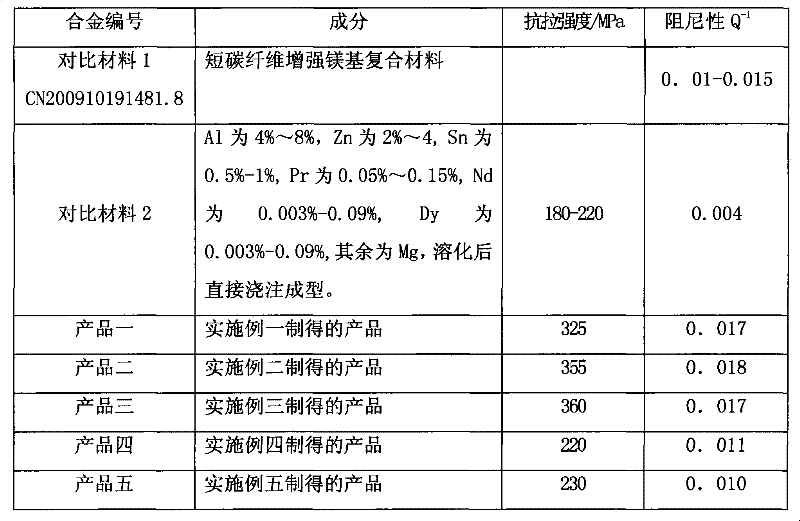

Fine grain titanium fiber pumice magnesium alloy composite material and preparation method thereof

The invention provides a lightweight fine grain titanium fiber pumice magnesium alloy composite material and a preparation method thereof. The composite material has high strength and excellent damping performance. The method has simple process and low production cost and is suitable for industrial production. The composite material takes magnesium alloy as a substrate on which fine grain titanium fibers and pumice particles are distributed, the size of grains of the fine grain titanium fibers is 1-10 mu m, the fine grain titanium fibers and the pumice particles account for 45-55% of the composite material by volume, and the weight ratio of the fine grain titanium fibers to the pumice particles is 1:1. The magnesium alloy substrate comprises the following chemical components in percentage by weight: 4%-8% of Al, 0.01%-0.05% of Gd, 0.01%-0.05% of Gr, 0.001%-0.005% of Mo, 0.03%-0.09% of Si, 0.003%-0.009% of V, 0.003%-0.09% of Sn and the balance Mg.

Owner:淮安市清河区科技转化服务中心

High-precision constant-temperature and constant-humidity air conditioner system and control method thereof

ActiveCN108679780AImprove supercooling effectIncrease conversion rateMechanical apparatusEngineeringMoisture

The invention discloses a high-precision constant-temperature and constant-humidity air conditioner system and a control method thereof. The high-precision constant-temperature and constant-humidity air conditioner system comprises an indoor unit and an outdoor air conditioner system module, wherein the indoor unit comprises a case, a mixing chamber formed in the case, a filtering chamber, a humidifying chamber, a temperature adjusting heating chamber and an air outlet section; the humidifying chamber is located between the filtering chamber and the temperature adjusting heating chamber; the outdoor air conditioner system module comprises an outdoor unit, a defrosting unit matched with the outdoor unit and a constant temperature water humidifying unit for humidifying the humidifying chamber. According to the high-precision constant-temperature and constant-humidity air conditioner system and the control method of the invention, indoor air is humidity adjusted by the constant temperature water supplied by the outdoor unit, and the heat-humidity exchange is performed in the humidifying section to control the absolute humidity of the air conditioner system; the air conditioner systemensures the humidity accuracy of the air conditioner system by controlling the absolute moisture content of the air outlet of the air conditioner system; and secondly, the air outlet temperature of the indoor unit is controlled by the temperature adjusting heating chamber separately, thereby achieving independent control of the air outlet temperature and humidity, and the control of the air outlettemperature and humidity is more accurate.

Owner:ZHEJIANG KING CO LTD

Refrigeration device

ActiveCN107014130AHigh precisionImprove supercooling effectLighting and heating apparatusDomestic refrigeratorsFreezing chamberEngineering

The invention provides a refrigeration device which comprises a freezing chamber, a freezing circulation system, a supply air path, a tray, a temperature sensor and an air blower. The freezing chamber is used for storing frozen food. The freezing circulation system comprises a compressor, a condenser, an expansion mechanism and an evaporator which are connected together, and refrigeration cold air is produced through cooling of the evaporator. The supply air path is used for conveying cold air produced by the evaporator. The tray is used for being detachably arranged inside the freezing chamber and bearing the frozen food. The tray is provided with multiple through holes. The temperature sensor is used for being arranged inside the freezing chamber and detecting the bottom temperature of the frozen food on the tray. The air blower is used for blowing cold air conveyed by the supply air path towards the tray at the lower portion inside the freezing chamber. Food is efficiently frozen through supercooling, and therefore the supercooling effect is improved.

Owner:QINGDAO HAIER SPECIAL ICEBOX +1

Copper tube structure of subcooler for air conditioner outdoor unit

InactiveCN102478329AImprove supercooling effectImprove abilitiesNoise suppressionSubcoolersVapor–liquid separatorEngineering

The invention discloses a copper tube structure of a subcooler for an air conditioner outdoor unit. The air conditioner outdoor unit comprises an enclosure with an accommodating space formed inside, a common gas-liquid separator, a plurality of compressors, an outdoor heat exchanger and the subcooler, wherein the common gas-liquid separator is arranged inside the enclosure and is used for performing gas-liquid separation on a refrigerant; the compressors are used for compressing the refrigerant flowing from the gas-liquid separator; the outdoor heat exchanger is arranged in an opening area of the enclosure so as to subject the inside refrigerant to heat exchange; and the subcooler is arranged between the outdoor heat exchanger and the compressors and is made of a copper tube, the cooper tube is of a dual-layer casing pipe structure composed of an inner tube and an outer tube, the inner tube is a threaded tube, and the outer tube is a common round tube. According to the invention, the subcooling performance of a system can be effectively increased, the noises can be reduced and the system performance can be improved.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Finely crystalline iron-stibium fiber and pumice magnesium alloy composite material and preparation method thereof

The invention provides a finely crystalline iron-stibium fiber and pumice magnesium alloy composite material and a preparation method thereof. The composite material has high strength, and excellent damping performance. The method has the advantages of simple process, low production cost and suitability for industrial production. The composite material has the magnesium alloy serving as a matrix,finely crystalline iron-stibium fibers and pumice microparticles are distributed on the matrix, the crystalline grains of the iron-stibium fibers are 1 to 10 mu m, and the fibers and the pumice account for 45 to 55 volume percent of the composite material, wherein the weight ratio of the fibers to the pumice is 1:1.

Owner:淮安市清河区科技转化服务中心

Fine-grained copper fiber, pumice and magnesium alloy composite material and preparation method thereof

The invention provides a lightweight fine-grained copper fiber, pumice and magnesium alloy composite material and a preparation method thereof, and the composite material has high strength and excellent damping performance. The method has simple process and low production cost and is applicable to industrial production. The composite material takes magnesium alloy as a matrix, fine-grained copper fiber and pumice micro-particles are distributed on the matrix, and the grain size of the fine-grained copper fiber is 1-10 mu m; the two of the fine-grained copper fiber and pumice accounts for 45%-55% of the composite material by volume percent, wherein the weight ratio of the fiber to the pumice is 1:1; and the magnesium alloy matrix comprises the following chemical components by weight percent: 4%-8% of Al, 2%-4% of Zn, 0.5%-1% of Sn, 0.05%-0.15% of Pr, 0.003%-0.09% of Nd, 0.03%-0.09% of Dy and the balance of Mg.

Owner:淮安市清河区科技转化服务中心

Fine grain titanium fiber pumice magnesium alloy composite material and preparation method thereof

The invention provides a lightweight fine grain titanium fiber pumice magnesium alloy composite material and a preparation method thereof. The composite material has high strength and excellent damping performance. The method has simple process and low production cost and is suitable for industrial production. The composite material takes magnesium alloy as a substrate on which fine grain titanium fibers and pumice particles are distributed, the size of grains of the fine grain titanium fibers is 1-10 mu m, the fine grain titanium fibers and the pumice particles account for 45-55% of the composite material by volume, and the weight ratio of the fine grain titanium fibers to the pumice particles is 1:1. The magnesium alloy substrate comprises the following chemical components in percentageby weight: 4%-8% of Al, 0.01%-0.05% of Gd, 0.01%-0.05% of Gr, 0.001%-0.005% of Mo, 0.03%-0.09% of Si, 0.003%-0.009% of V, 0.003%-0.09% of Sn and the balance Mg.

Owner:淮安市清河区科技转化服务中心

Finely crystalline iron-stibium fiber and pumice magnesium alloy composite material and preparation method thereof

Owner:淮安市清河区科技转化服务中心

Corrosion resistance coating for steel and preparation method thereof

The invention provides a corrosion resistance coating for steel and a preparation method thereof. The coating has the advantages of excellent performance and good wear resistance. The preparation method has the advantages of simple process and low production cost and is suitable for industrial production. The corrosion resistance coating for steel comprises the following compositions in percentage by weight: 40-45 percent of alloy powder, 3.0-6.0 percent of boron nitride powder, 3-6 percent of silicon carbide powder, 7.0-8.0 percent of butanol powder and the balance of epoxy resin liquid, wherein the particle size of the alloy powder, the particle size of the boron nitride powder and the particle size of the silicon carbide powder are all 270-800 meshes. The alloy powder comprises the following compositions in percentage by weight: 35-40 percent of Zn, 0.01-0.1 percent of Mn, 0.2-0.4 percent of Cd, 0.2-0.4 percent of Sr, 0.02-0.05 percent of Si, 0.03-0.09 percent of Prm 0.05-0.2 percent of Gd and the balance of Al.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Corrosion resistant coating for metal magnesium and preparation method thereof

InactiveCN101875810BHigh strengthImprove supercooling effectAnti-corrosive paintsEpoxy resin coatingsEpoxyChemical composition

The invention provides a corrosion resistant coating for metal magnesium and a preparation method thereof. The coating has favorable corrosion resistance. The preparation method has the advantages of simple process and low production cost and is suitable for industrial production. The corrosion resistant coating used for metal magnesium comprises the following chemical compositions in percentage by weight: 40-45wt% of alloy powder, 3-6wt% of titanium carbonitride powder, 3-6wt% of silicon nitride powder, 7-8wt% of butanol and the balance of epoxy resin liquid. The grain sizes of alloy powder, titanium carbonitride powder and silicon nitride powder are 270-800 meshes. The alloy powder comprises the following components in percentage by weight: 2-4wt% of Cu, 0.01-0.1wt% of Sn, 0.2-0.4wt% of Sb, 3-6wt% of Si, 0.03-0.09wt% of Pr and the balance of Ni.

Owner:江苏渝鑫科技股份有限公司

refrigeration equipment

ActiveCN107036370BCool evenlyEvenly wrappedLighting and heating apparatusDomestic refrigeratorsEngineeringFreezing chamber

The invention provides refrigerating equipment. The refrigerating equipment comprises a freezing chamber used for containing frozen objects, a freezing circulating system comprising a compressor, a condenser, an expansion mechanism and an evaporator which are connected together, an air supply path used for conveying cool air generated by the evaporator, a pallet used for bearing the frozen objects in the freezing chamber and provided with a plurality of through holes, and a blower used for blowing the cool air conveyed by the air supply path towards the pallet on the lower portion in the freezing chamber, wherein the evaporator is used for generating refrigerating cool air through cooling; and an air supply cavity is formed in the bottom of the pallet and used for receiving the cool air conveyed by the air supply path and discharging the cool air through through holes in the bottom of the pallet upwards. Food is frozen effectively through supercooling so that the supercooling effect can be improved.

Owner:QINGDAO HAIER SPECIAL ICEBOX +1

Air-cooled refrigeration equipment

ActiveCN107014129BHigh precisionImprove supercooling effectLighting and heating apparatusDomestic refrigeratorsCold airEngineering

Owner:QINGDAO HAIER SPECIAL ICEBOX +1

refrigeration unit

ActiveCN107014130BHigh precisionImprove supercooling effectLighting and heating apparatusDomestic refrigeratorsCold airEngineering

The invention provides a refrigeration device which comprises a freezing chamber, a freezing circulation system, a supply air path, a tray, a temperature sensor and an air blower. The freezing chamber is used for storing frozen food. The freezing circulation system comprises a compressor, a condenser, an expansion mechanism and an evaporator which are connected together, and refrigeration cold air is produced through cooling of the evaporator. The supply air path is used for conveying cold air produced by the evaporator. The tray is used for being detachably arranged inside the freezing chamber and bearing the frozen food. The tray is provided with multiple through holes. The temperature sensor is used for being arranged inside the freezing chamber and detecting the bottom temperature of the frozen food on the tray. The air blower is used for blowing cold air conveyed by the supply air path towards the tray at the lower portion inside the freezing chamber. Food is efficiently frozen through supercooling, and therefore the supercooling effect is improved.

Owner:QINGDAO HAIER SPECIAL ICEBOX +1

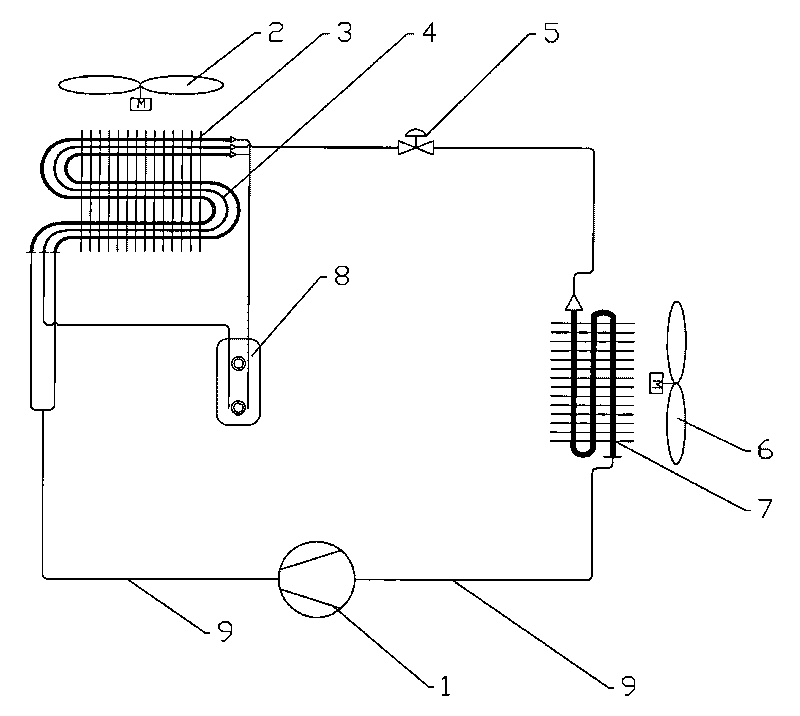

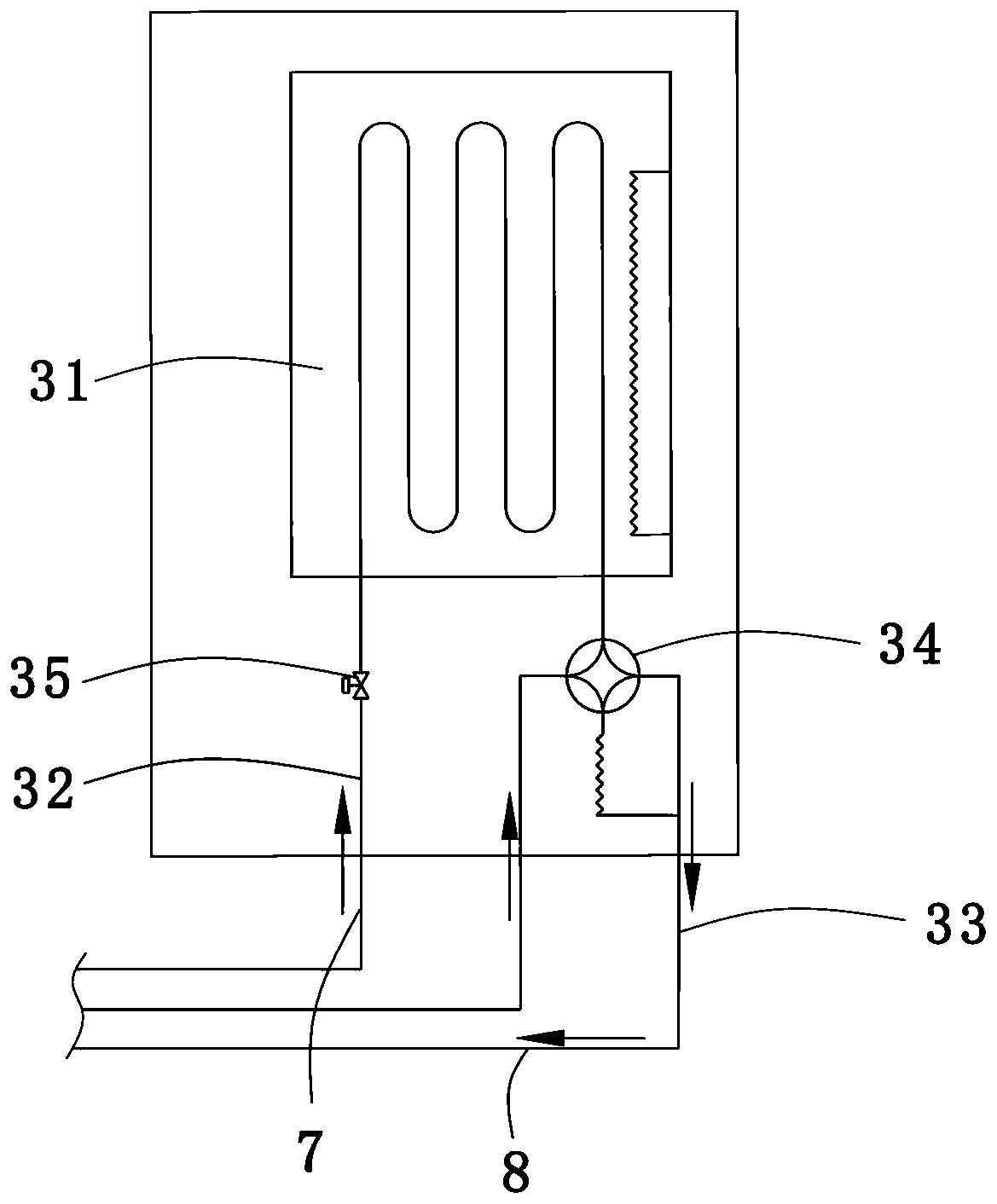

Big supercooling degree machine room air conditioner

InactiveCN101576328BSolve the problem of subcooling reductionEfficient use ofCompression machines with non-reversible cycleEvaporators/condensersEngineeringHigh pressure

The invention discloses a big supercooling degree machine room air conditioner. A condenser consists of two parallel condenser tubes; and a supercooler is positioned between the two parallel condensertubes of the condenser. The refrigeration cycle comprises that: a refrigerant is converted into high-temperature high-pressure gas by the compressor, enters the two parallel condenser tubes of the condenser to exchange heat with air and enters a high-pressure liquid reservoir; the refrigerant flowing out of the high-pressure liquid reservoir enters a supercooler for supercooling heat exchange andbecomes the refrigerant with a big supercooling degree; the refrigerant with the big supercooling degree is throttled by an expanding valve and enters an evaporator for heat exchange; and finally therefrigerant is returned to the compressor to complete the whole refrigeration cycle. Because the refrigerant is supercooled after the high-pressure liquid reservoir, the problem that the supercoolingdegree is lowered because the conventional refrigerant is supercooled and then enters the high-pressure liquid reservoir is effectively solved; and because of the big supercooling degree, the refrigerant does not bubble when passing the expanding valve, the operating stability and reliability of the expanding valve are improved, and the refrigerating capacity and the refrigerating energy efficiency of the system are also improved.

Owner:NANJING NORMAL UNIVERSITY +2

An ultra-high precision constant temperature and humidity air conditioning system and control method

ActiveCN108758795BImprove supercooling effectIncrease conversion rateMechanical apparatusLighting and heating apparatusIndoor airEngineering

The invention discloses a constant-temperature and constant-humidity air conditioner system with ultrahigh precision and a control method. The constant-temperature and constant-humidity air conditioner system comprises an indoor unit and an outdoor unit module, wherein the indoor unit comprises a case as well as a mixing chamber, a filtering chamber, a humidifying chamber, a temperature-adjustingheating chamber and an air outlet section which are formed in the case; the humidifying chamber is located between the filtering chamber and the temperature-adjusting heating chamber; the outdoor unitmodule comprises an outdoor unit, a defrosting unit matched with the outdoor unit and a constant-temperature water humidification unit for executing humidification operation on the humidifying chamber. Indoor air is subjected to humidity adjustment by means of constant-temperature water provided by the outdoor unit, heat-humidity exchange is performed in the humidifying section to control absolute humidity of air output by the unit, and humidity precision of the air conditioner unit is guaranteed by controlling the absolute moisture content of the air output by the unit; temperature of outletair of the indoor unit is controlled separately by the temperature-adjusting heating chamber, so that independent control over temperature and humidity of the outlet air is realized, and control overthe temperature and the humidity of the outlet air is more accurate.

Owner:ZHEJIANG KING CO LTD

Supercooling Control Method of Refrigeration Equipment

ActiveCN106931718BImprove supercooling effectHigh precisionLighting and heating apparatusCooling fluid circulationEngineeringRefrigeration plant

The invention provides a supercooling control method of refrigerating equipment. The supercooling control method comprises the steps that 1, after a supercooling mode is started, a compressor and a first air feeder operate intermittently; 2, when the temperature detected by a temperature sensor is lower than a first set temperature value T1, the compressor and the first air feeder operate continuously; 3, when the temperature detected by the temperature sensor is lower than a second set temperature value T2, the compressor and the first air feeder operate intermittently, and a second air feeder operates continuously; and 4, when the temperature detected by the temperature sensor is lower than a third set temperature value T3, the refrigerating equipment operates according to a conventional refrigerating mode, specifically, T1>T2>T3. Food is frozen efficiently through supercooling so that the supercooling effect can be improved.

Owner:QINGDAO HAIER SPECIAL ICEBOX +1

A kind of high-chromium chromium-molybdenum steel plate and production method thereof

The invention discloses a high-chromium chromium-molybdenum steel plate and a production method thereof. The steel plate is composed of the following components in percentage by weight: 0.09%-0.15% of C, 0.5%-0.90% of Si, 0.30%-0.60% of Mn, at most 0.007% of P, at most 0.005% of S, 8.00%-10% of Cr, 0.90%-1.1% of Mo, at most 0.20% of Cu, 0.05%-0.10% of Ni, at most 0.003% of Sb, at most 0.005% of Sn, at most 0.012% of As, and the balance of Fe and inevitable impurities. The production method comprises the following steps: smelting and die casting, heating and rolling, and heat treatment. The high-chromium chromium-molybdenum steel plate satisfies the requirements of high strength, high toughness and high processability for domestic power equipment industry, and can be widely used for manufacturing of domestic power equipment. The steel plate has the advantages of favorable cold bending property, no cracking in the material manufacturing process, and favorable resilience.

Owner:WUYANG IRON & STEEL

Heat exchanger with good supercooling effect and air conditioning unit

PendingCN112066605AOvercoming the Problem of Flow Dead ZonesImprove spoiler effectEvaporators/condensersHeat exchanger casingsCold mediumEngineering

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com