Big supercooling degree completely fresh air air processing machine set

An air handling unit and subcooling technology, which is applied in the direction of subcoolers, refrigerators, refrigeration components, etc., can solve the problem of affecting the use effect of direct evaporative fresh air air handling units, affecting the system supercooling effect, and the expansion valve is not working properly. Stability and other issues, to achieve the effect of improving the cooling energy efficiency ratio, enhancing stability and reliability, and increasing the degree of subcooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

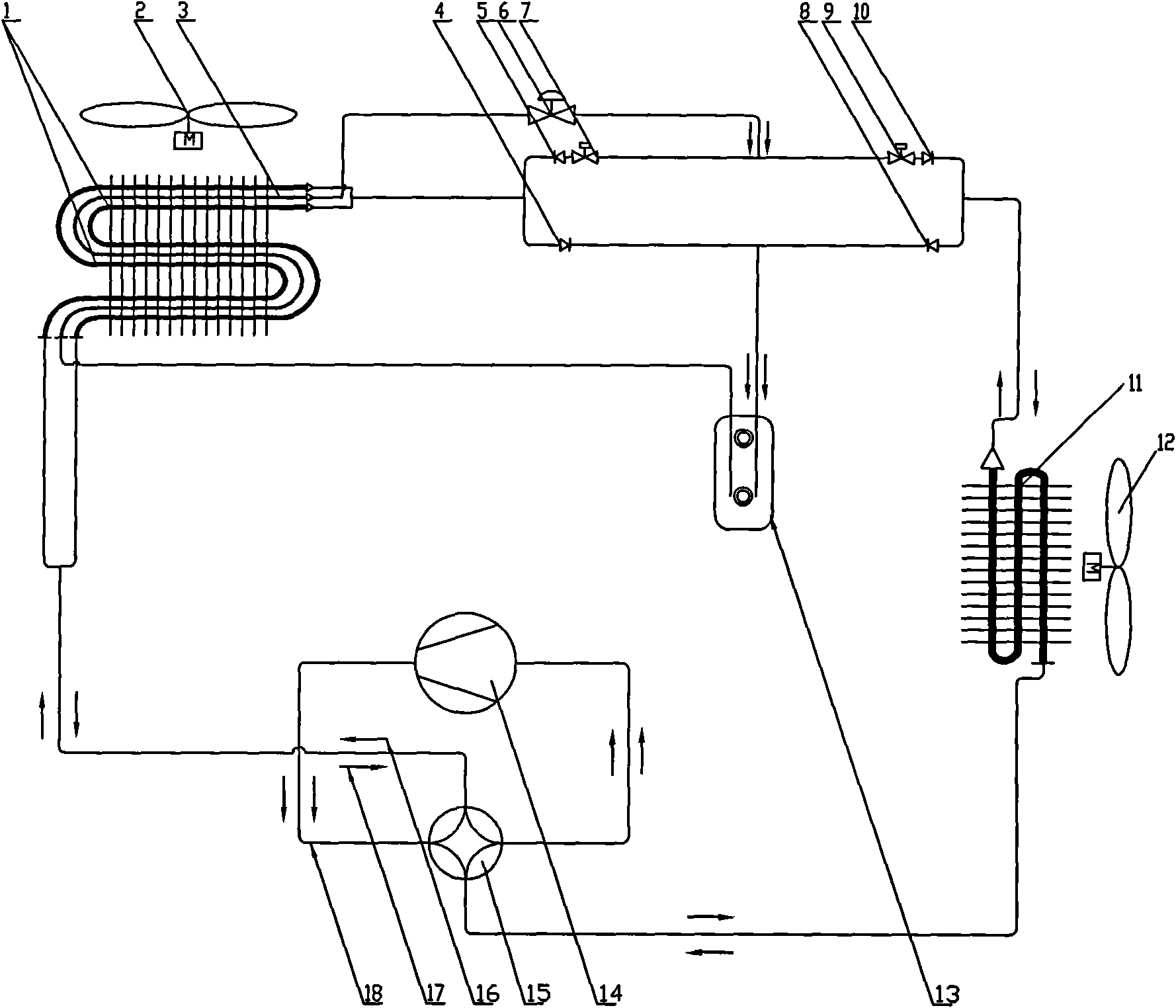

[0016] Such as figure 1 As shown, the compressor 14 is respectively connected to the outdoor processing unit heat exchanger 1 and the indoor air supply unit heat exchanger 11 after passing through the four-way reversing valve 15; the outdoor processing unit heat exchanger 1 passes through the liquid reservoir (high pressure liquid storage tank ) 13, subcooler 3, throttle valve 6 and indoor air supply unit heat exchanger 11 are connected; two different working conditions of heating and cooling in winter and summer are changed through four-way reversing valve 15; In different cycles of heating and cooling, check valves 4, 5, 8, 10 and solenoid valves 7, 9 are turned off and on to ensure that the pipeline system follows the flow of the accumulator 13, the subcooler 3 and the throttle valve 6. process to work. A fan 2 and a fan 12 are arranged above the heat exchanger 1 of the outdoor processing unit and the heat exchanger 11 of the indoor air supply unit to carry out air deliver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com