Finely crystalline iron-stibium fiber and pumice magnesium alloy composite material and preparation method thereof

A composite material and magnesium alloy technology, applied in the field of high damping fine-grained iron antimony fiber pumice magnesium alloy composite material and its preparation, can solve problems such as complex process and achieve the effect of enhancing supercooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

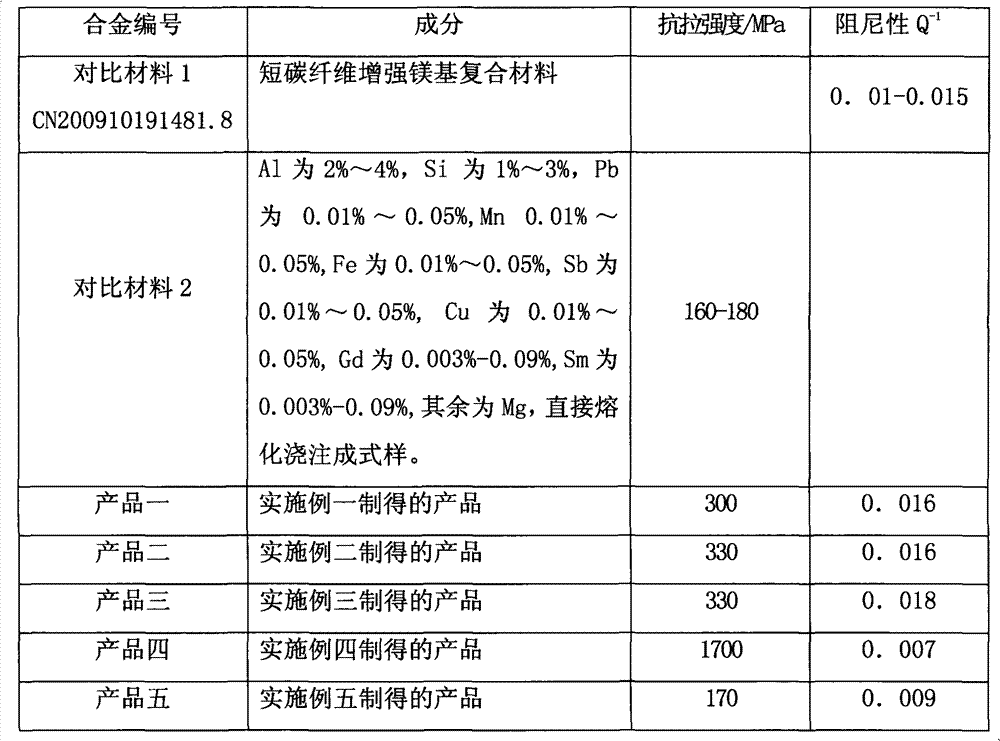

Examples

Embodiment 1

[0025] Preparation of fine-grained iron-antimony fiber: by weight percentage, Sb is 5%, Cu is 0.003%, Sm is 0.003%, Gd is 0.05%, and the rest is Fe for batching; raw materials are placed in a riser with a heating device It melts to form iron alloy liquid; the melting temperature is 1580-1600°C. The lower part of the riser pipe is equipped with a plunger, driven by the power unit, the plunger can move up and down along the riser pipe. The liquid is pulled out to form fine-grained iron-antimony fibers, and the runner adopts a water-cooled copper alloy runner with a flange on the rim. The alloy liquid contacts the flange of the rotating water-cooled copper alloy runner through the liquid riser, and the flange of the water-cooled copper alloy runner pulls the alloy liquid out to form alloy material fibers. The linear speed of the runner flange is 19-21m / s. Turn on the water-cooling system of the runner before the runner starts running, and the temperature of the water entering th...

Embodiment 2

[0030]Magnesium alloy substrate by weight percentage: Al is 4%, Si is 3%, Pb is 0.05%, Mn is 0.05%, Fe is 0.05%, Sb is 0.05%, Cu is 0.05%, Gd is 0.09%, Sm is 0.09%, and the rest is Mg for batching;

[0031] The content of fine-grained iron-antimony fiber by weight percentage: Sb is 10%, Cu is 0.09%, Sm is 0.09%, Gd is 0.2%, and the rest is Fe for batching; the volume of fine-grained iron-antimony fiber and pumice when preparing the prefabricated body The ratio is 1:1, pumice is a silicate containing aluminum, potassium, and sodium, and its specific composition: SiO2 accounts for 65%-75%, Al2O3 accounts for 9%-12%, and the rest is CaO, MgO and Fe2O3.

[0032] The added amount of the silica sol is 1-2% of the total weight of the fine-grained iron-antimony fiber and the pumice mixture, and the fine-grained iron-antimony fiber and the pumice are controlled to account for 55% of the volume of the magnesium alloy matrix. Its preparation process is with embodiment one.

Embodiment 3

[0034] Magnesium alloy substrate by weight percentage: Al is 3%, Si is 2%, Pb is 0.03%, Mn is 0.045%, Fe is 0.04%, Sb is 0.03%, Cu is 0.03%, Gd is 0.009%, Sm is 0.009%, the rest is Mg for batching;

[0035] Fine-grained iron-antimony fiber by weight percentage: Sb is 7%, Cu is 0.009%, Sm is 0.009%, Gd is 0.1%, and the rest is Fe for batching;

[0036] When preparing the preform, the volume ratio of fine-grained iron-antimony fiber and pumice is 1:1, and the addition of silica sol is 1-2% of the total weight of the fine-grained iron-antimony fiber and pumice mixture to control the fine-grained iron-antimony fiber and pumice. Accounting for 45% of the volume of the magnesium alloy matrix.

[0037] Its preparation process is with embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com