Fine-grained copper fiber, pumice and magnesium alloy composite material and preparation method thereof

A composite material and copper fiber technology, applied in the field of metal materials, can solve problems such as complex processes, and achieve the effects of simple preparation process, superior damping performance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

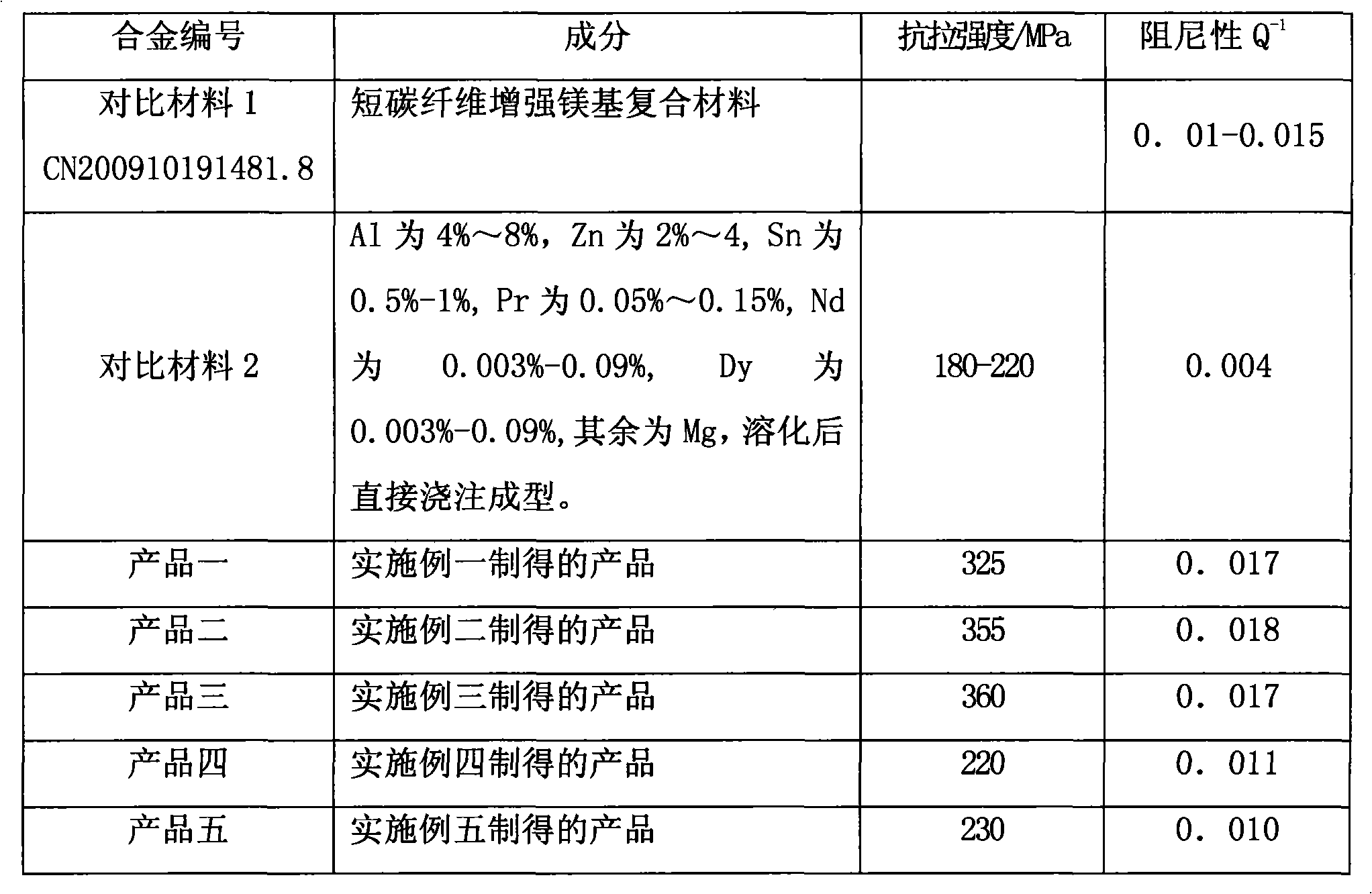

Embodiment 1

[0026] Preparation of fine-grained copper fiber: by weight percentage: Al is 6%, V is 0.5%, Zn is 20%, Pr is 0.05%, Nd is 0.0039%, Dy is 0.003%, and the rest is Cu for batching;

[0027] The raw material is melted in a liquid riser with a heating device to form an alloy liquid, and the heating temperature is 1150-1200°C. The lower part of the riser pipe is equipped with a plunger, driven by the power unit, the plunger can move up and down along the riser pipe. The liquid is pulled out to form fine-grained copper fibers, and the runner adopts a water-cooled copper alloy runner with a flange on the rim. The alloy liquid contacts the flange of the rotating water-cooled copper alloy runner through the liquid riser, and the flange of the water-cooled copper alloy runner pulls the alloy liquid out to form fine-grained copper fibers. The linear speed of the runner flange is 22-24m / s , Turn on the water-cooling system before the runner starts to run, and the temperature of the water ...

Embodiment 2

[0031] The content of the magnesium alloy matrix by weight percentage: Al is 8%, Zn is 4%, Sn is 1%, Pr is 0.15%, Nd is 0.09%, Dy is 0.09%, and the rest is Mg.

[0032] Fine-grained copper fiber by weight percentage: Al is 8%, V is 1%, Zn is 25%, Pr is 0.15%, Nd is 0.09%, Dy is 0.09%, and the rest is Cu.

[0033]In the preparation of the fine-grained copper fiber pumice preform: the volume ratio of the fine-grained iron-antimony fiber to the pumice is 1:1. The fine-grained copper fiber and pumice are controlled to account for 45% of the volume percentage of the composite material.

[0034] The preparation process is the same as in Example 1.

Embodiment 3

[0036] The content of the magnesium alloy matrix by weight percentage: Al is 6%, Zn is 3%, Sn is 0.8%, Pr is 0.1%, Nd is 0.009%, Dy is 0.009%, and the rest is Mg.

[0037] Fine-grained copper fiber by weight percentage: Al is 7%, V is 0.8%, Zn is 22%, Pr is 0.09%, Nd is 0.009%, Dy is 0.009%, and the rest is Cu.

[0038] In the preparation of the fine-grained copper fiber pumice preform: the volume ratio of the fine-grained iron-antimony fiber to the pumice is 1:1. Control the fine-grained copper fiber and pumice to account for 55% of the volume percentage of the composite material.

[0039] The preparation process is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com