Oil-line corrosion and gas monitoring system of transformer

A gas monitoring and transformer technology, applied in the field of monitoring, can solve the problems of overheating or partial discharge failure of the oil circuit for a long time, and achieve the effect of strong applicability and simple system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

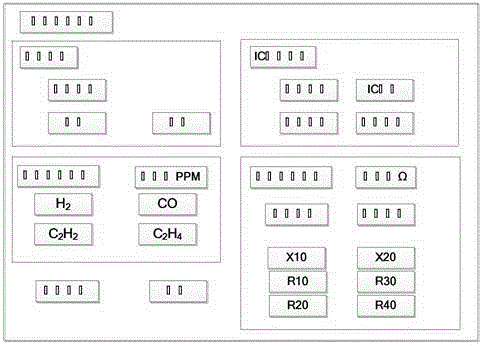

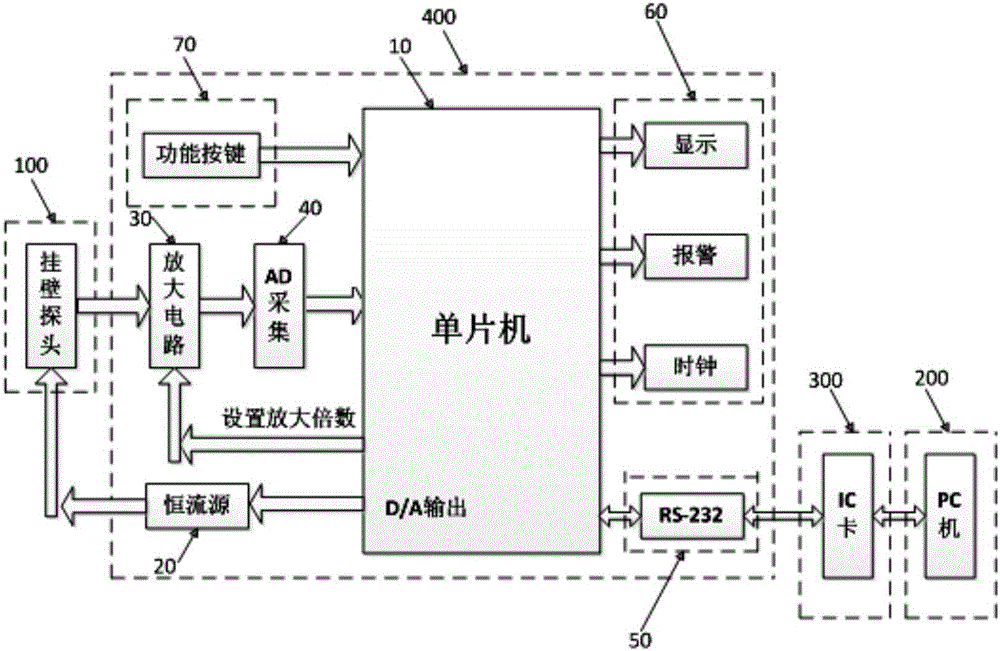

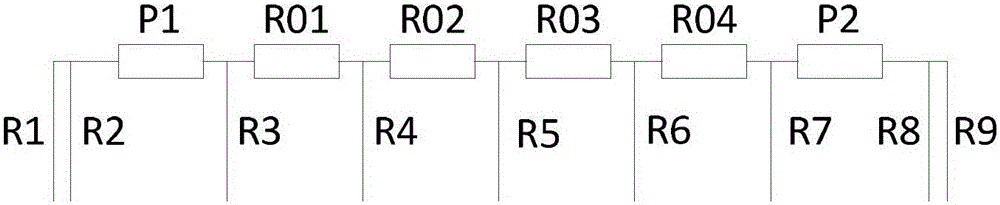

[0013] The oil circuit is not affected by the external electric field and magnetic field, and the resistance probe and gas sensor can be directly placed on the inner wall of the oil pipeline, so as to realize real-time online monitoring without stopping the transformer, and can find out the oil circuit and electric circuit of the transformer Internal failure. In order to express the change of transformer oil pipeline corrosion sensitively and quickly, it is required to measure the micro-ohm level change of the pipeline corrosion resistance coupon. In order to effectively suppress the corrosion when it occurs on the pipeline surface, the resolution of the measurement system must reach 1μΩ level. The probe integrated with the chip resistor includes a gas sensor, which converts the gas information in the monitored transformer oil into an electrical signal in real time; the electrical signal passes through the common communication controller with the chip resistor, and then is tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com