Device for simulating graphite dust emission during break accident of high-temperature reactor and discharge testing method

A technology of graphite dust and high-temperature reactors, which is applied in the testing of machines/structural components, measuring devices, fluid dynamics tests, etc., and can solve problems such as unrealistic emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

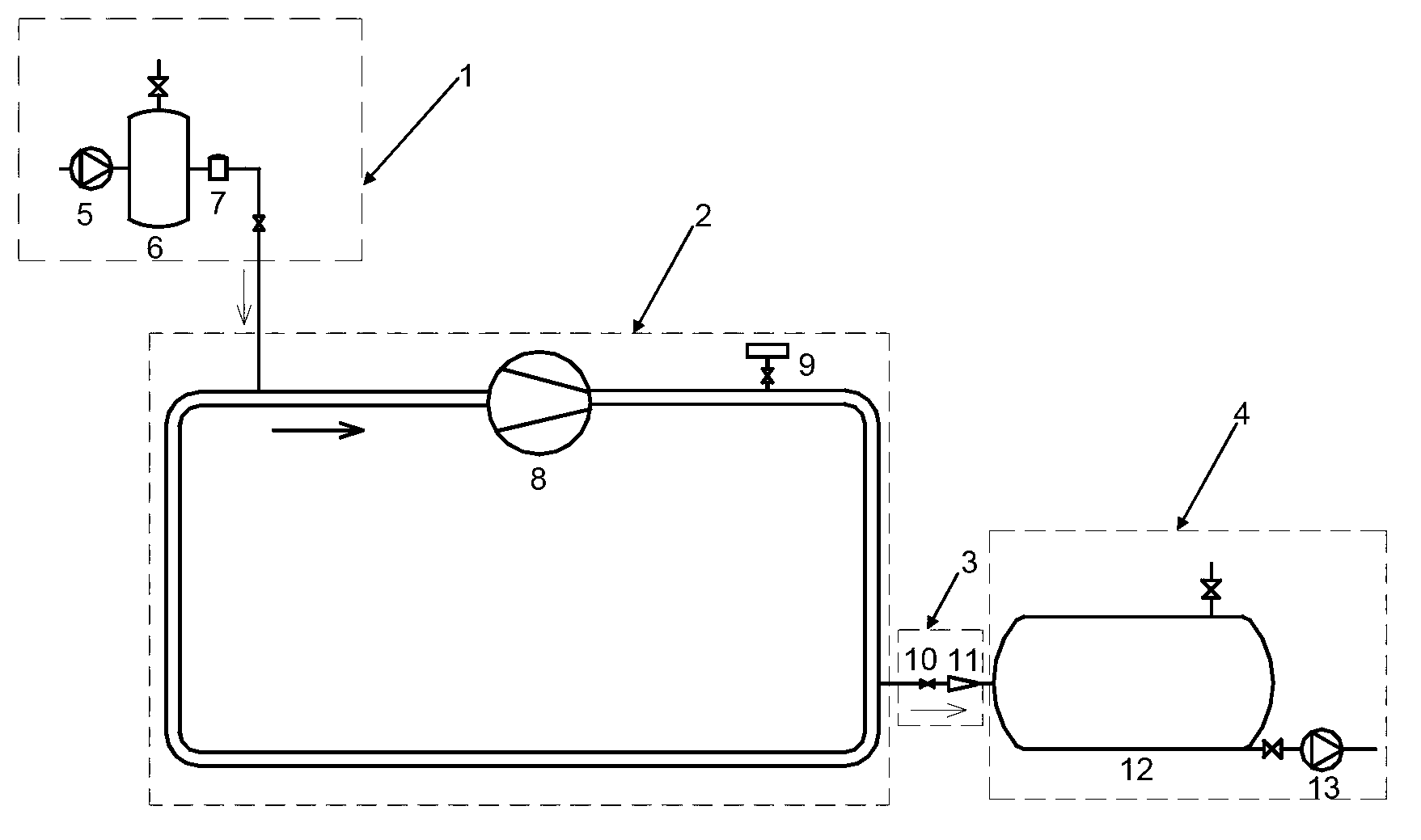

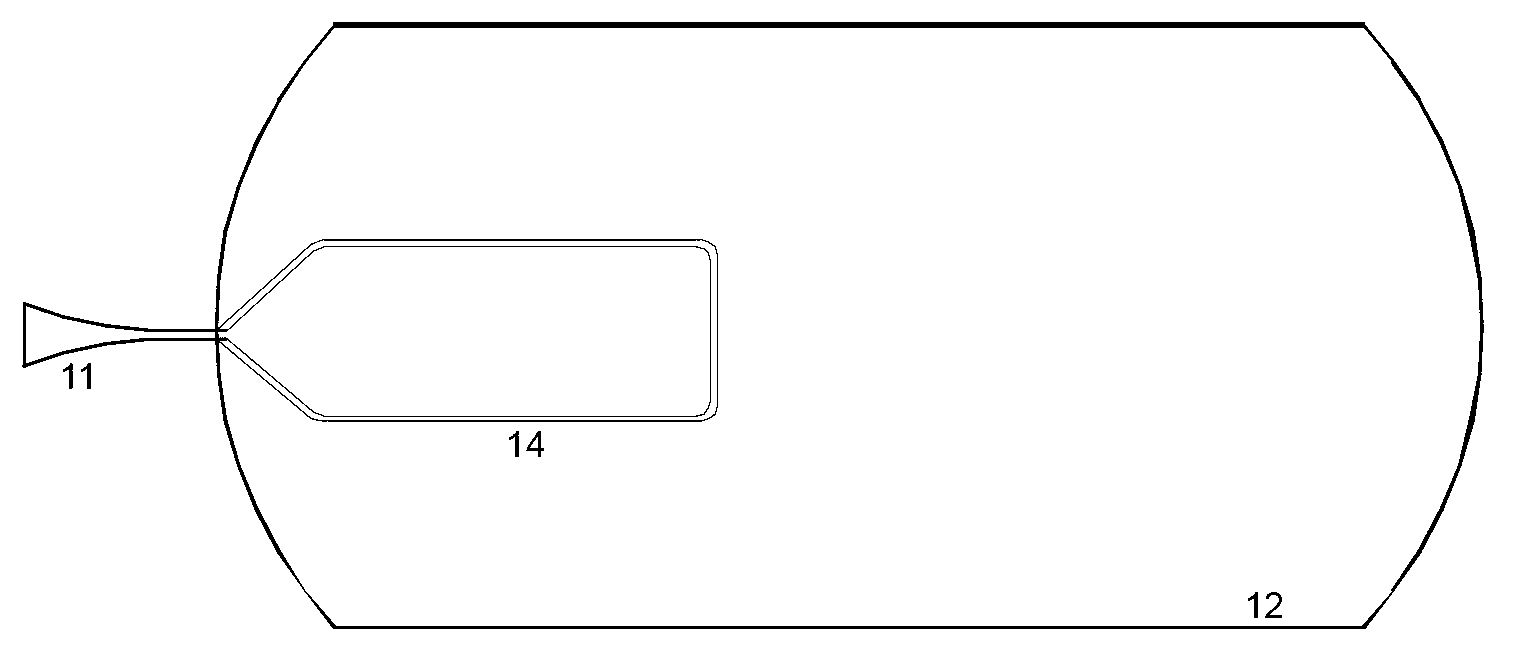

[0021] Such as figure 1 , figure 2 As shown, the embodiment of the present invention provides a measurement of graphite dust emission in a high-temperature gas-cooled reactor under accident conditions, which includes: a pressure injection system 1, a main circuit piping system 2, a nozzle discharge system 3, and a vacuum tank system 4.

[0022] The air in the external environment is injected into the high-pressure air storage tank 6 through the air compressor 5. After the pressure is stabilized, it is dedusted and dehumidified by the dryer 7 and then enters the main circuit pipeline. After the main circuit pressure requirements are met, the inflation is stopped and the circulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com