Loop design for slot type solar heat power plant

A trough-type solar energy and thermal power generation technology, applied in solar thermal power generation, solar thermal energy, solar collectors, etc., can solve problems affecting the safe and normal operation of the system, pipeline leakage, etc., to reduce heat loss, avoid corrosion, and ensure safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

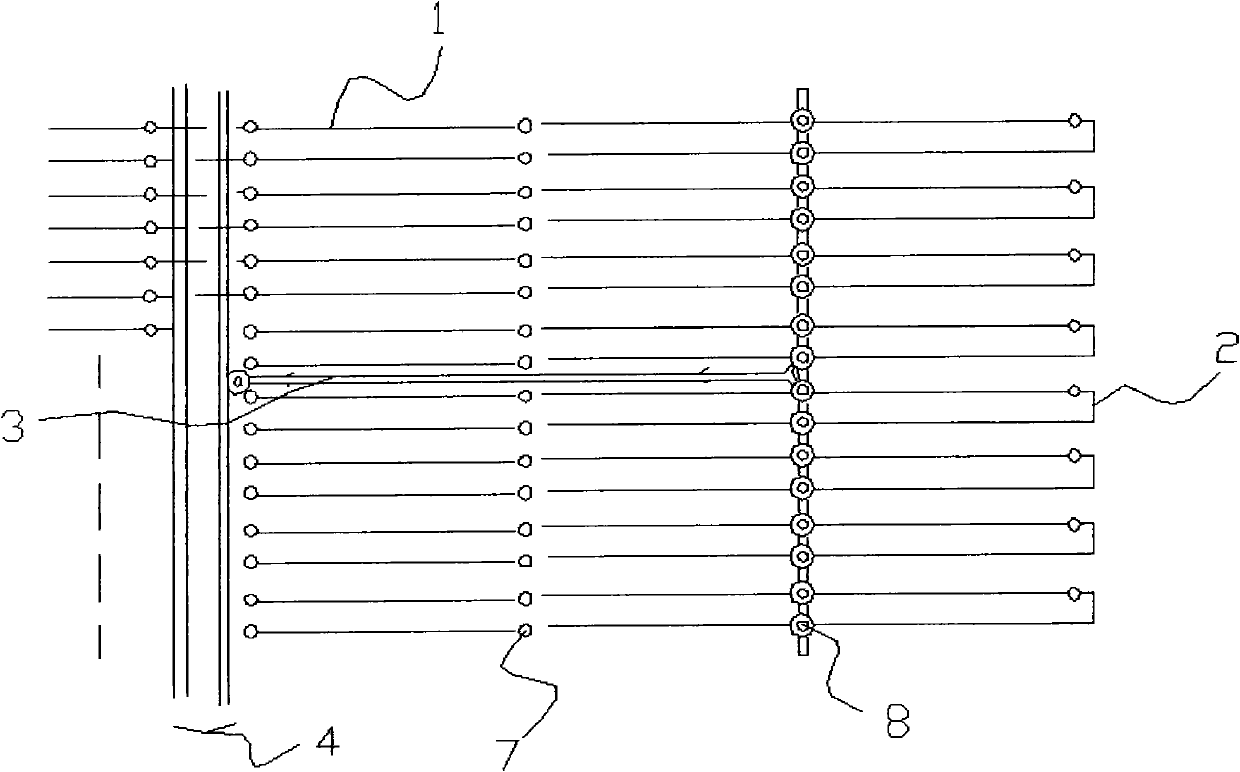

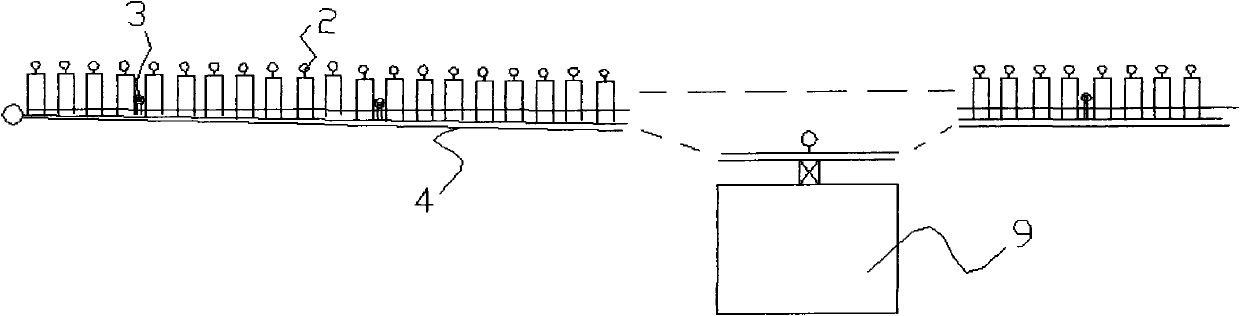

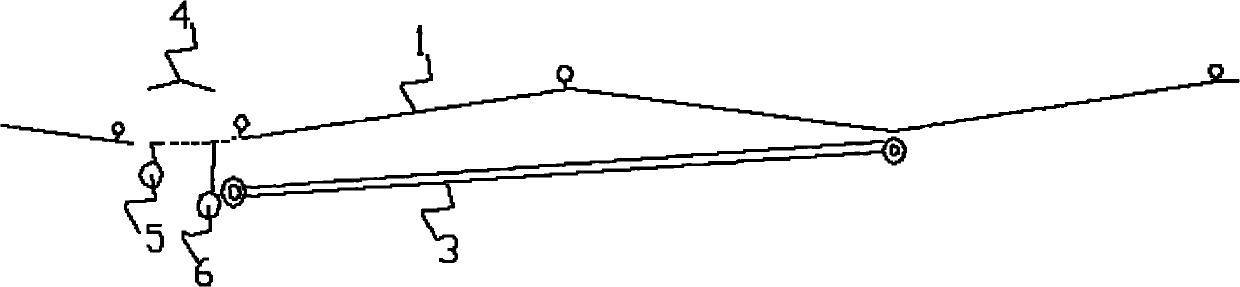

[0017] Such as figure 1 , figure 2 , image 3 As shown, a circuit design of a trough solar thermal power plant is set in a trough solar heat collection field. The heat collection field is divided into several heat collector units, and a heat collector unit includes a parabolic mirror that can track and concentrate light and The heat collector tube 1 placed on the focal line of the parabolic mirror, each heat collector unit has a small inclination angle to the ground, the inclination angle cannot be too large, so that the relative height difference between the two ends of the heat collector unit does not exceed 1m, and the adjacent The collector tubes 1 of the two collector units are connected, and the highest or lowest point of the collector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com