Double-faced automatic upper disk and lower disk weaving mechanism of underwear machine and pneumatic color spacing mechanism arm device

The technology of an underwear machine and a manipulator is applied in weft knitting, a circular machine for weft knitting with a single action needle, and knitting, which can solve problems such as poor effect and affecting production efficiency, and achieve a simple structure and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

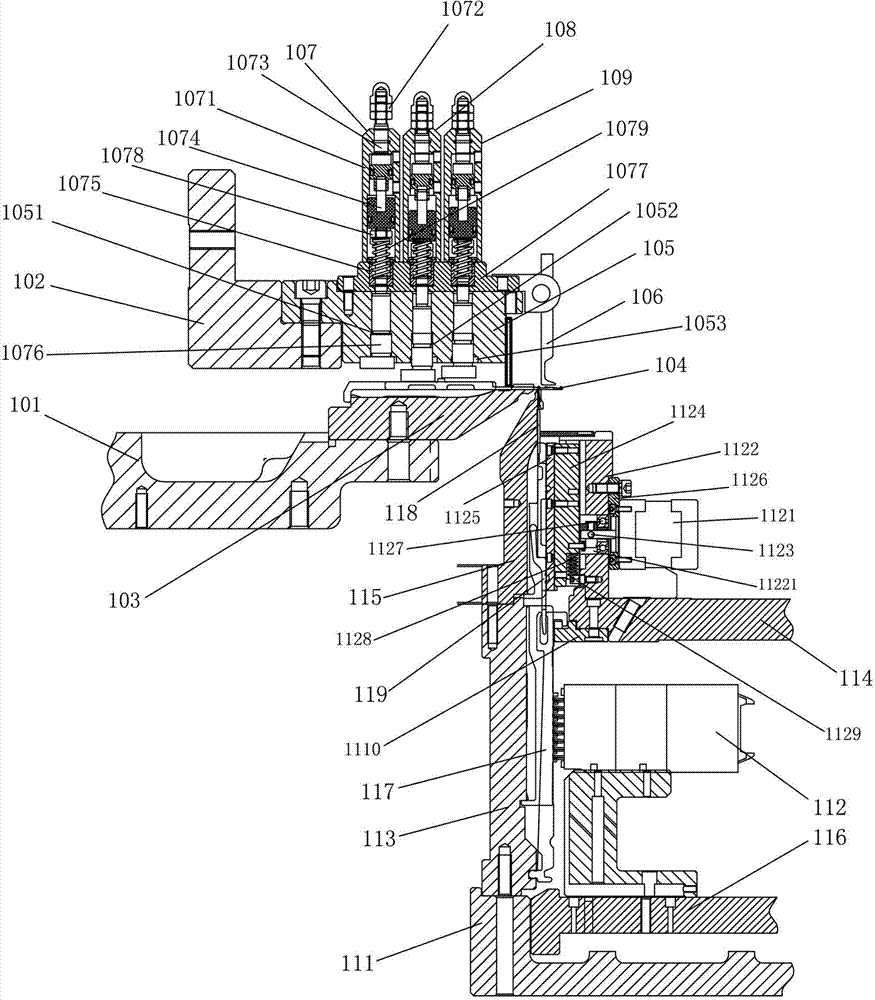

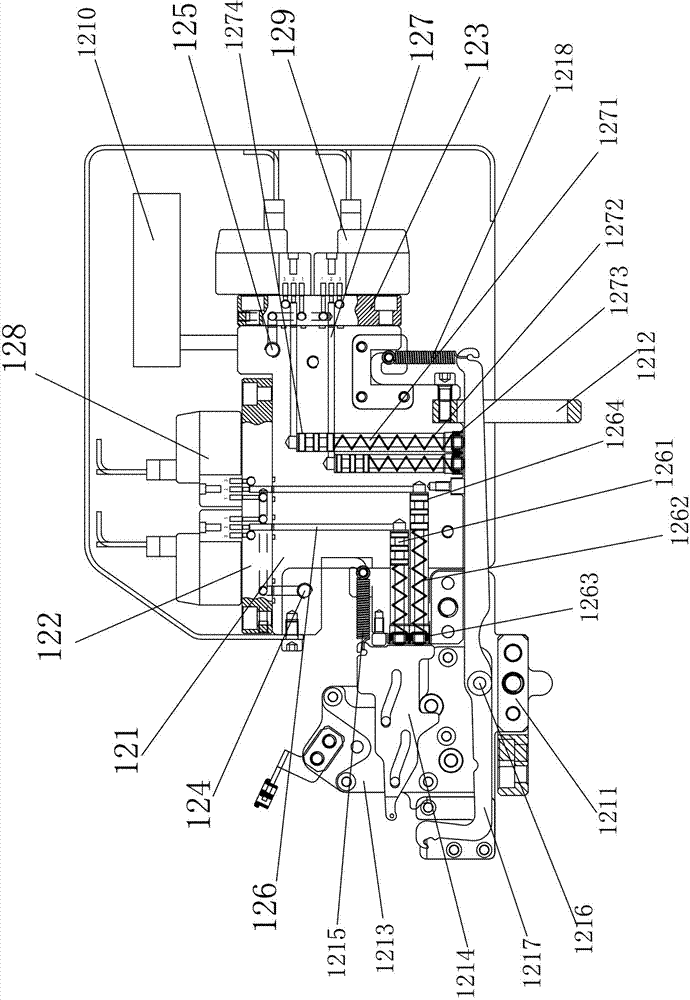

[0018] like figure 1 , figure 2As shown, a double-sided automatic underwear machine with an upper and lower plate knitting mechanism and a pneumatic intercolor manipulator device, including an upper pan knitting mechanism 10, a lower pan knitting mechanism 11 and a pneumatic intercolor manipulator 12; the upper pan knitting mechanism 10 includes a dial base 101 And cutting disc base 102, described dial base 101 is positioned at the below of cutting disc base 102; Described dial base 101 is connected with dial 103, and described dial 103 is connected with some upper needles 104 with high and low pins; The cutting disk base 102 is connected with a cutting disk 105; the cutting disk 105 is located above the dial 103; the right end of the cutting disk 105 is connected with a yarn feeder 106; The latches of the upper needle 104 of the stitches are connected; the cutting disk 105 is connected with a cylinder needle selection device; the cutting disk 105 is provided with a first ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com