Large-section tunnel circular blasting and tunnelling method

A large-section, tunnel technology, applied in the field of tunnel blasting, can solve the problems of inability to achieve cyclic excavation, unsatisfactory blasting effect, unsatisfactory effect, etc., to save waste rock scraping time, improve drilling efficiency, The effect of saving money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0021] refer to Figure 1 ~ Figure 3 As shown, the large-section tunnel circular blasting excavation method in one embodiment provided by the present invention comprises the following steps:

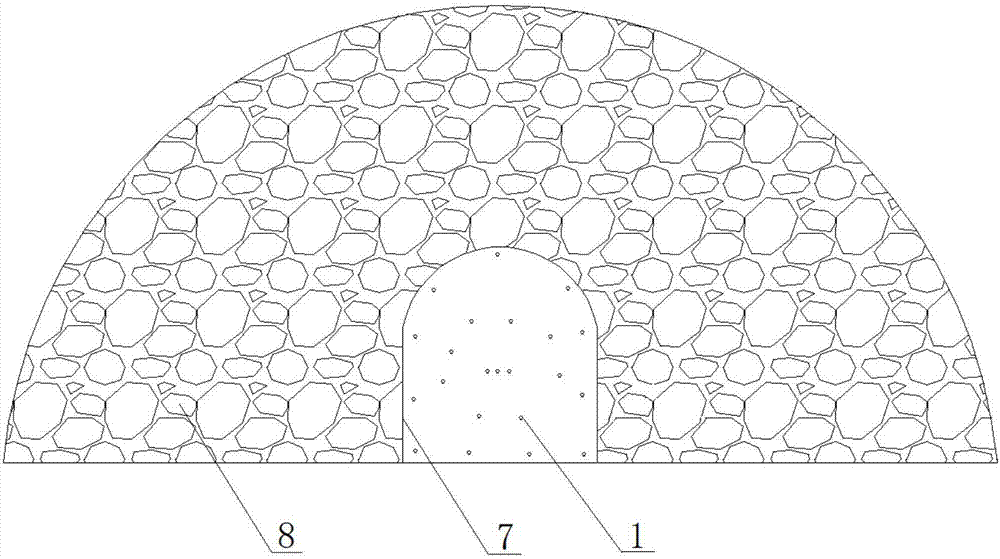

[0022] 1) In the middle of the bottom end of the tunnel face of the large-section tunnel 8, a guide tunnel 7 of a certain depth is excavated along the extension direction of the large-section tunnel 8;

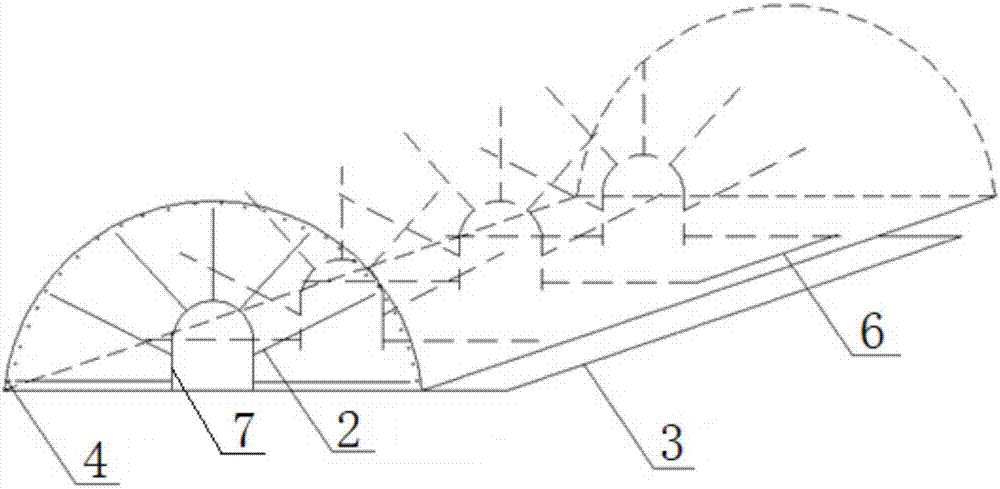

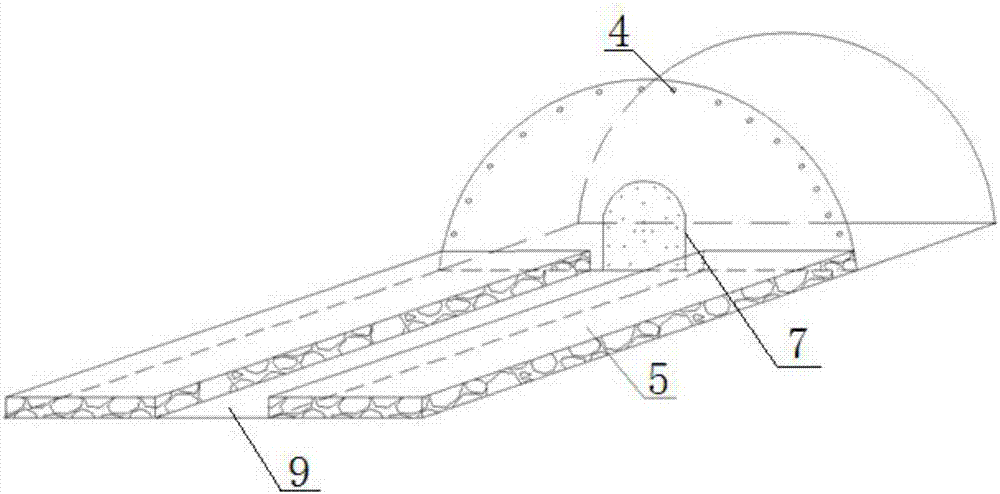

[0023] 2) Take the guide tunnel 7 as the free surface, drill guide holes 2 along the radial direction at a certain depth on multiple cross-sections of the guide tunnel 7, and a plurality of guide holes 2 are fan-shaped distributed along the guide tunnel 7;

[0024] 3) At the edge of the fan-shaped contour formed by the distribution of a plurality of guide holes 2, a plurality of large-section peripheral holes 4 are drilled along the axis direction of the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com