Bamboo block thermal shaping method and device

A technology of thermal shaping and bamboo block, which is applied in wood processing equipment, manufacturing tools, etc., can solve the problems of low material yield, and achieve the effect of simple device structure, small crack width and crack depth, and reduced elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

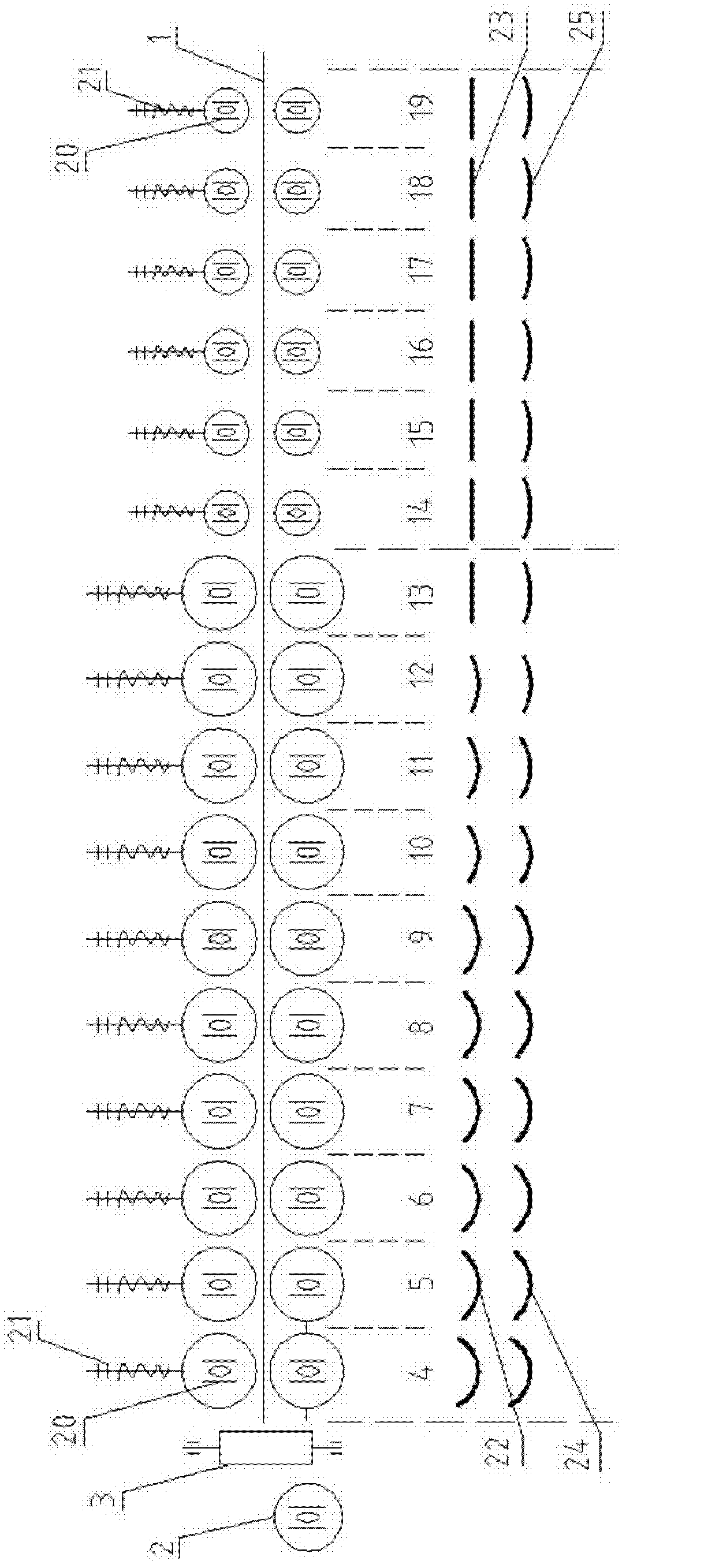

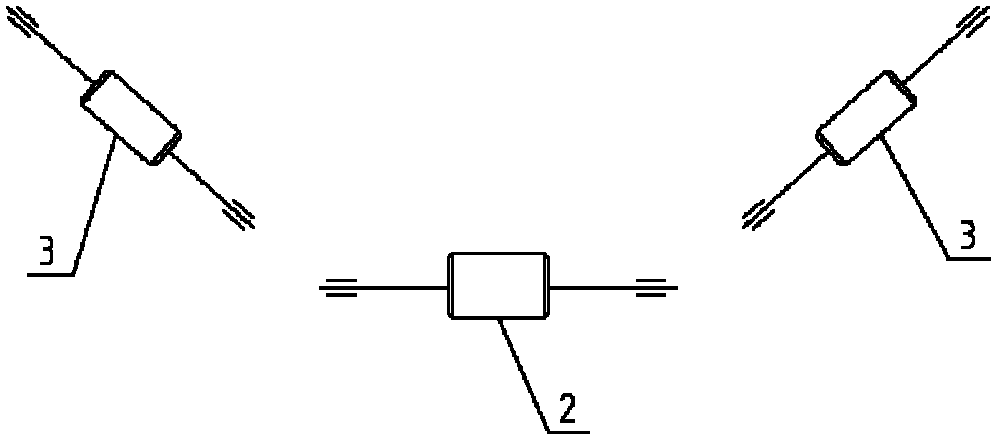

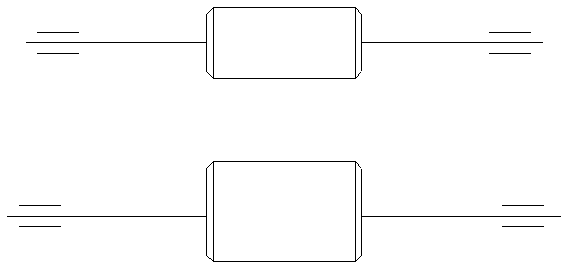

[0038] see figure 1 , figure 2, in the embodiment of the present invention, the device that is used for thermal shaping of bamboo block comprises the horizontal supporting roller 2 that is used to convey the arc-shaped bamboo block that is installed under the leftmost end of frame platform 1 and the lateral guide roller that its left end both sides are installed 3. On the frame platform 1, the first stage profile roll 4, the profile roll 5 to the profile roll 13 of other stages are installed successively, and the cooling and setting roll 14 to the cooling and setting roll 19 of each level behind it. The upper roll width of the first stage profiled roll 4 is narrower than its lower roll width, and the upper roll width of other level profiled rolls gradually increases to be consistent with its lower roll width, and the lower roll width of eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com