Antistatic ABS (Acrylonitrile Butadiene Styrene) laminated board

An anti-static, veneer technology, applied in the direction of layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the problems of unstable anti-static effect, high raw material cost, unstable electrical performance, etc., and reach the market. The effect of stable price, good flatness and stable electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

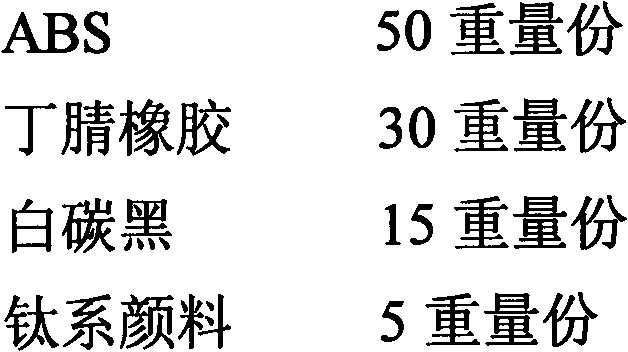

[0015] The antistatic ABS veneer of the present invention is composed of a static dissipative layer and a conductive layer. Wherein the content of each component in the gained static dissipative layer is:

[0016]

[0017] Wherein the content of each component in the conductive layer is:

[0018] ABS 50 parts by weight

[0019] 35 parts by weight of conductive carbon black

[0020] 15 parts by weight of zinc oxide.

[0021] Mix the above-mentioned rubber-plastic compound and other components of the antistatic layer on a banbury mixer. The temperature of the banbury mixer is 120 degrees, and the banbury time is 1 hour; The temperature is 100 degrees, and the refining time is 1 hour; the final product has stable electrical properties, high heat resistance, good flattening performance, and good anti-static effect.

Embodiment 2

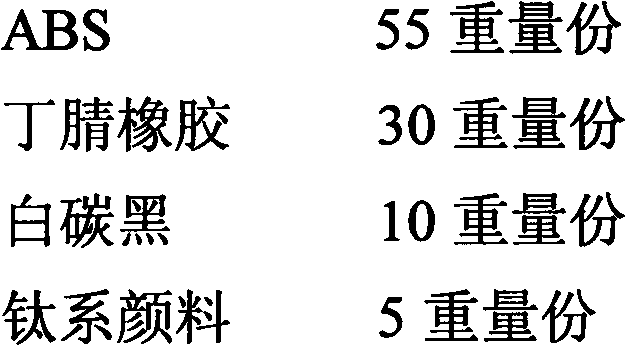

[0023] The antistatic ABS veneer of the present invention is composed of a static dissipative layer and a conductive layer. Wherein the content of each component in the gained static dissipative layer is:

[0024]

[0025] Wherein the content of each component in the conductive layer is:

[0026] ABS 55 parts by weight

[0027] 30 parts by weight of conductive carbon black

[0028] 15 parts by weight of zinc oxide.

[0029] Mix the above-mentioned rubber-plastic compound and other components of the antistatic layer on a banbury mixer. The temperature of the banbury mixer is 120 degrees, and the banbury time is 1 hour; The temperature is 100 degrees, and the refining time is 1 hour; the final product has stable electrical properties, high heat resistance, good flattening performance, and good anti-static effect.

Embodiment 3

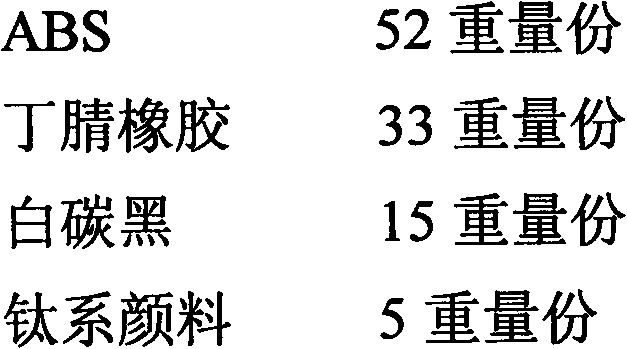

[0031] The antistatic ABS veneer of the present invention is composed of a static dissipative layer and a conductive layer. Wherein the content of each component in the gained electrostatic dissipative layer is:

[0032]

[0033] Wherein the content of each component in the conductive layer is:

[0034] ABS 52 parts by weight

[0035] 33 parts by weight of conductive carbon black

[0036] 15 parts by weight of zinc oxide.

[0037] Mix the above-mentioned rubber-plastic compound and other components of the antistatic layer on a banbury mixer. The temperature of the banbury mixer is 120 degrees, and the banbury time is 1 hour; The temperature is 100 degrees, and the refining time is 1 hour; the final product has stable electrical properties, high heat resistance, good flattening performance, and good anti-static effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com