Polishing head for chemico-mechanical polishing

A technology of chemical machinery and polishing head, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, grinding heads, etc., which can solve the problems of poor mechanical properties and achieve the effect of improving the planarization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

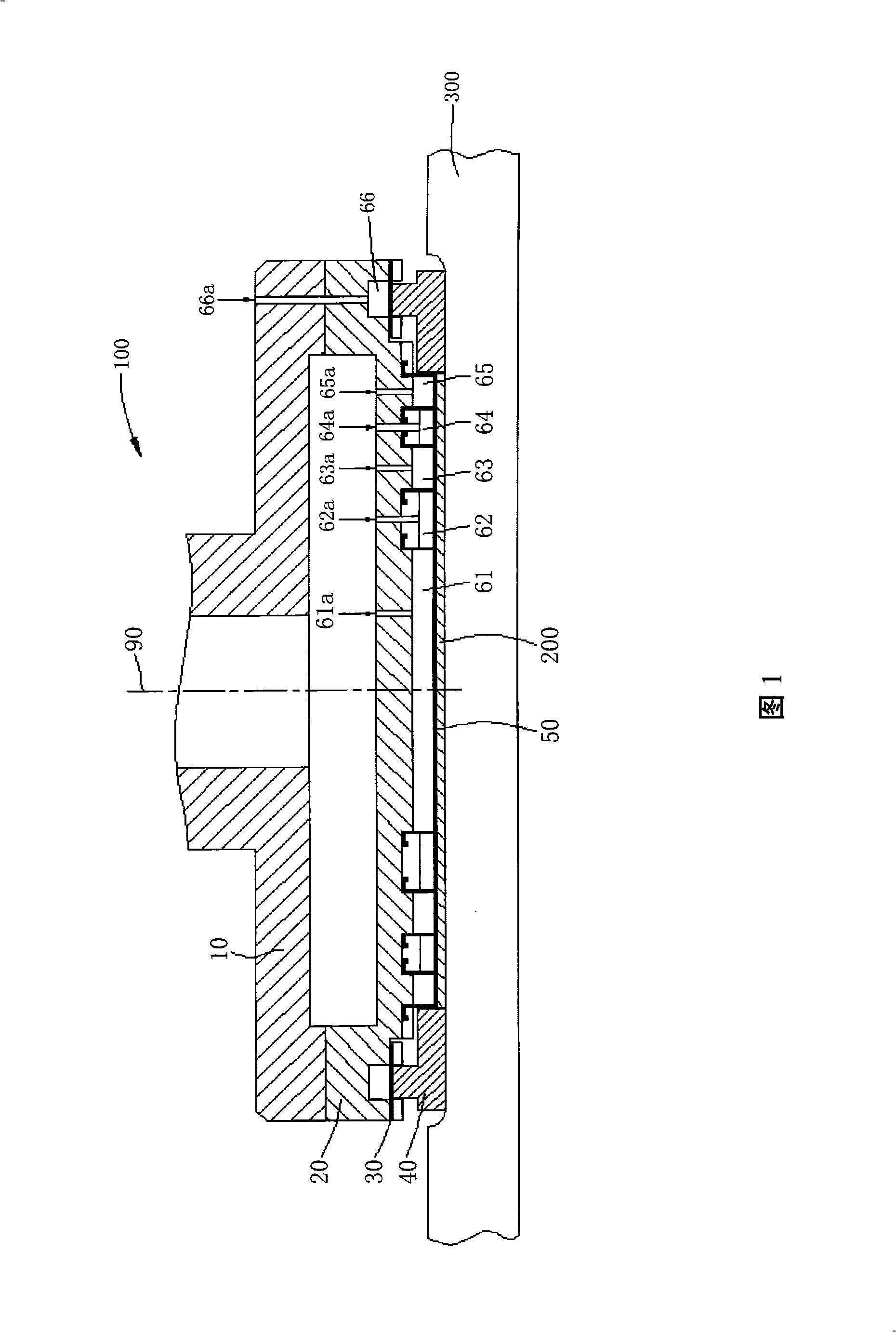

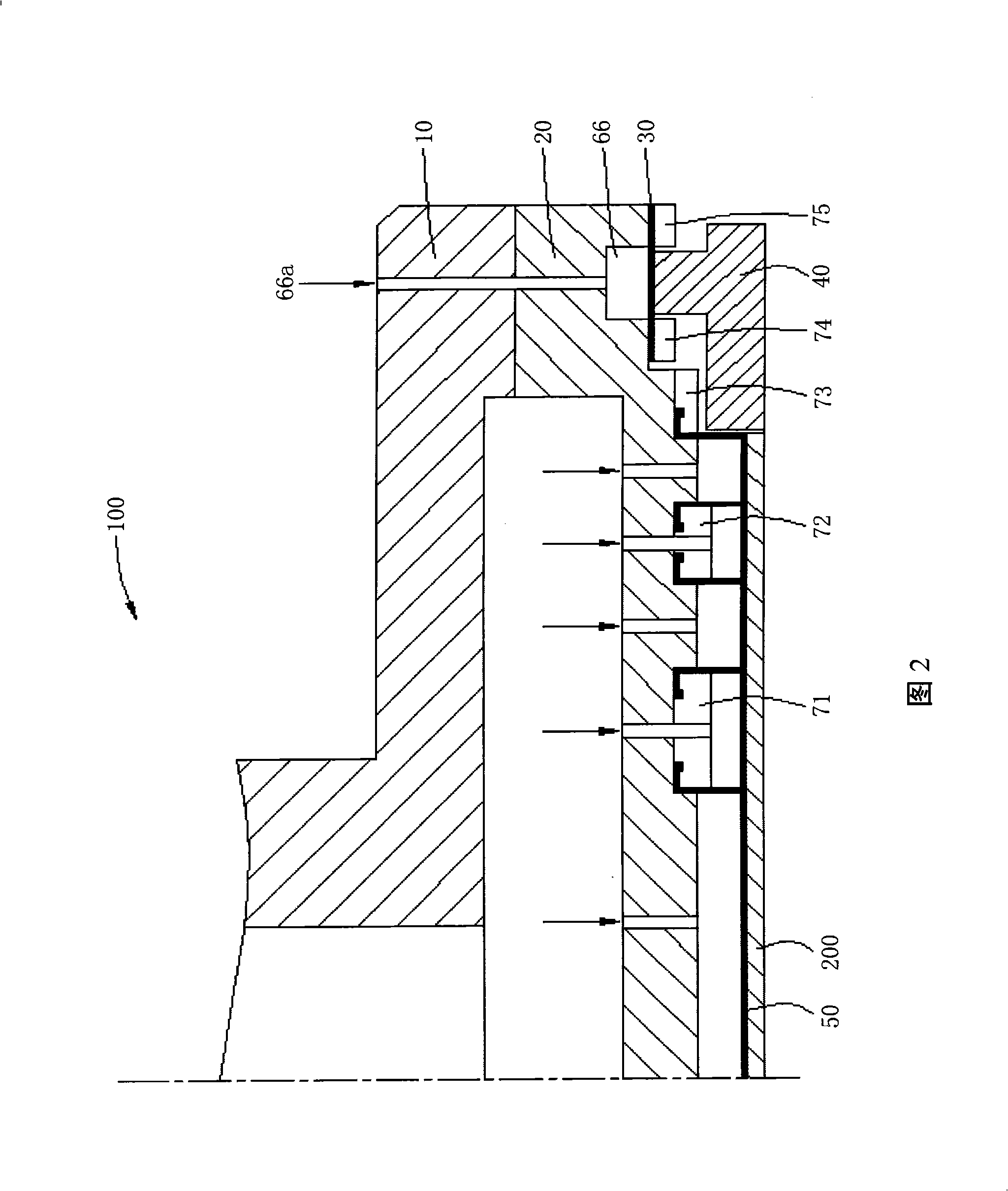

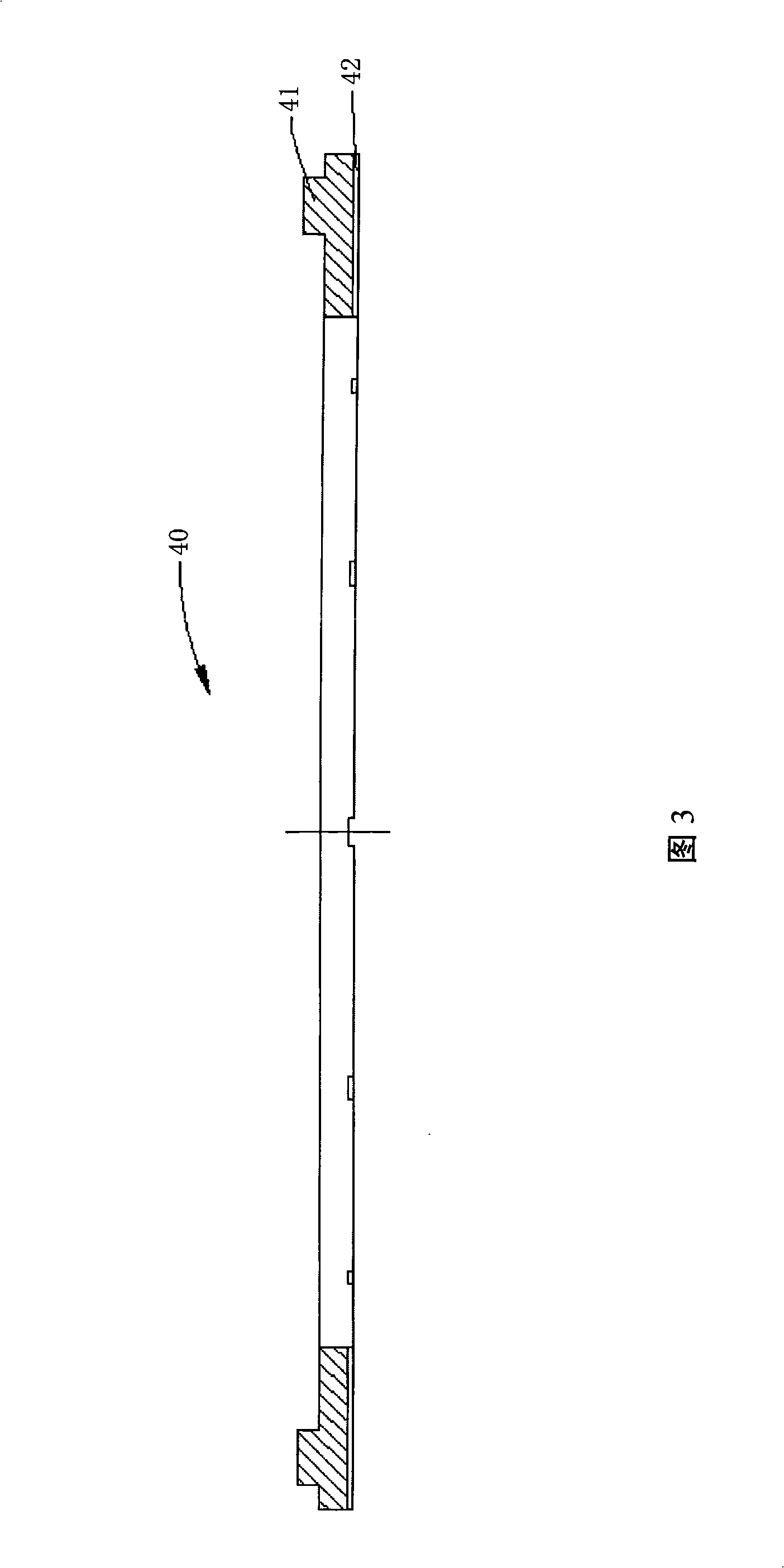

[0030] 1 and 2 are schematic cross-sectional structural views of a polishing head 100 according to a preferred embodiment of the present invention. The polishing head 100 includes an upper shell 10 , a base 20 , a retaining ring diaphragm 30 , a retaining ring 40 and a multi-chamber diaphragm 50 .

[0031] The upper housing 10 can be connected with a driving shaft, and the driving shaft drives the wafer 200 to rotate along the axis 90 in a fixed direction during the polishing process. The driving shaft is perpendicular to the polishing pad 300 during the polishing process. The upper casing 10 is cylindrical, and its outer diameter is about 250mm for a 200mm wafer, and ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com