Flattening device for waste carton recycling

A technology for cartons and waste, which is applied in the field of flattening devices for recycling waste cartons, which can solve the problems of low work efficiency, high labor costs, and inability to guarantee the flattening effect of waste cartons, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

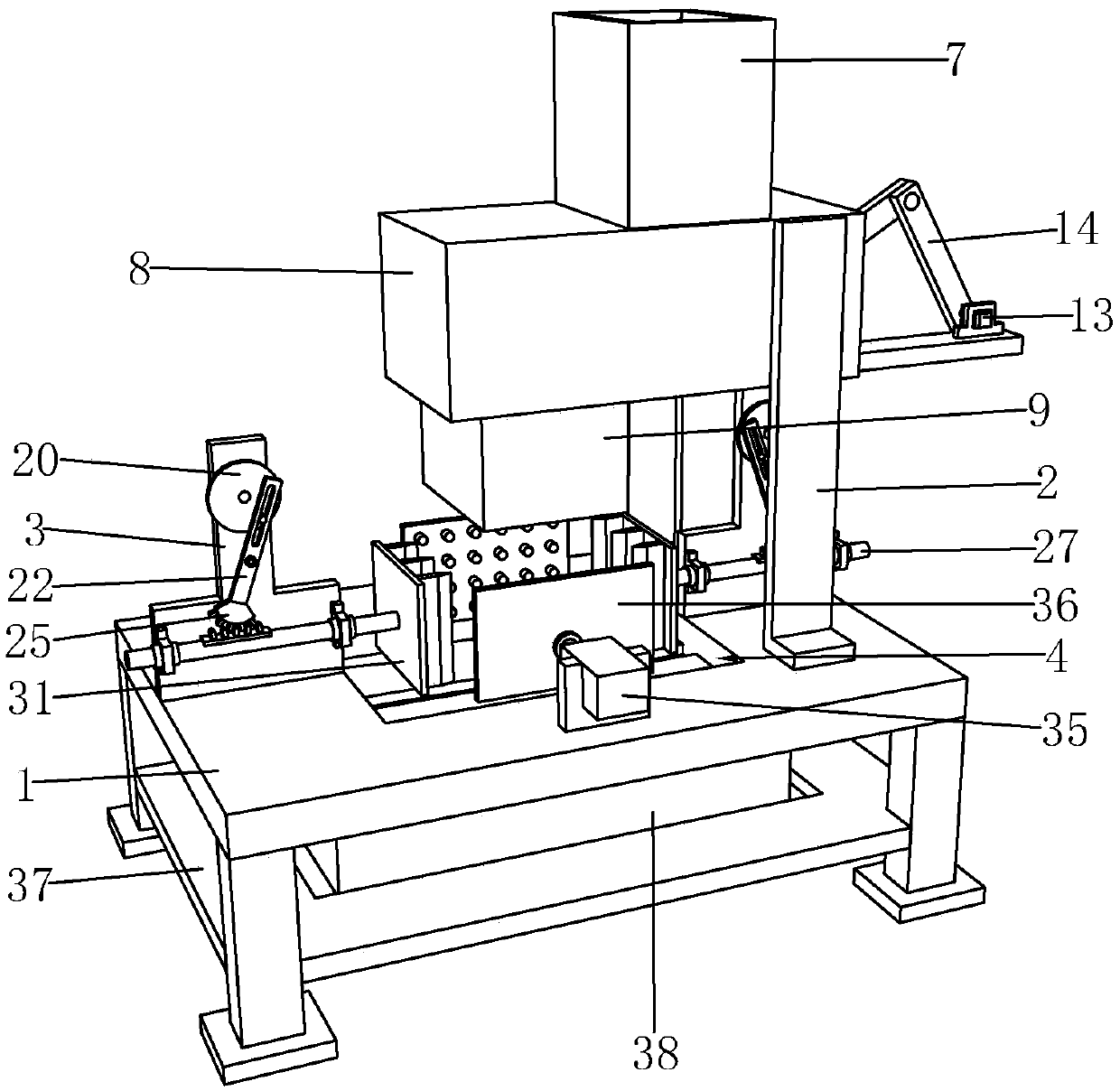

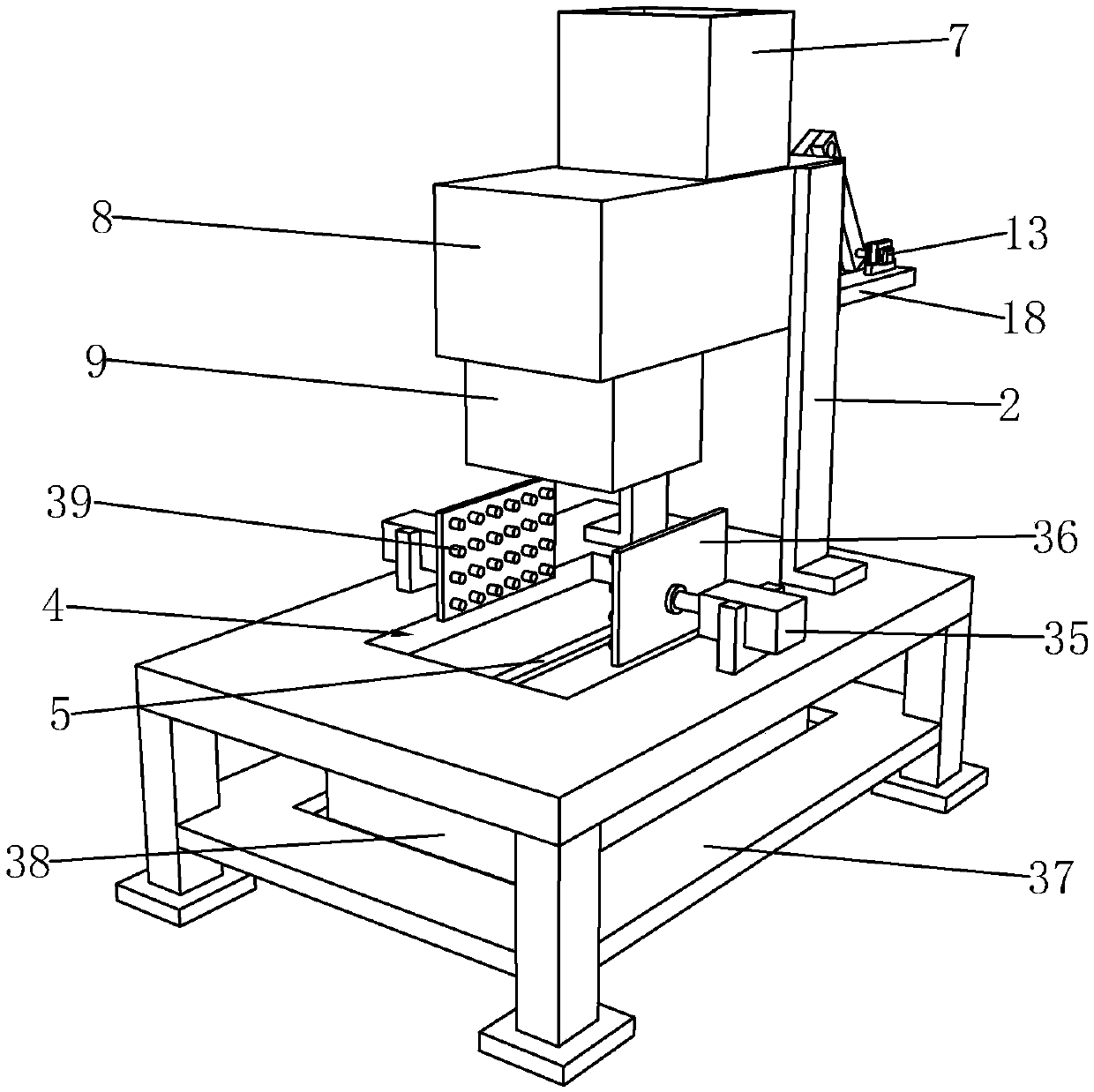

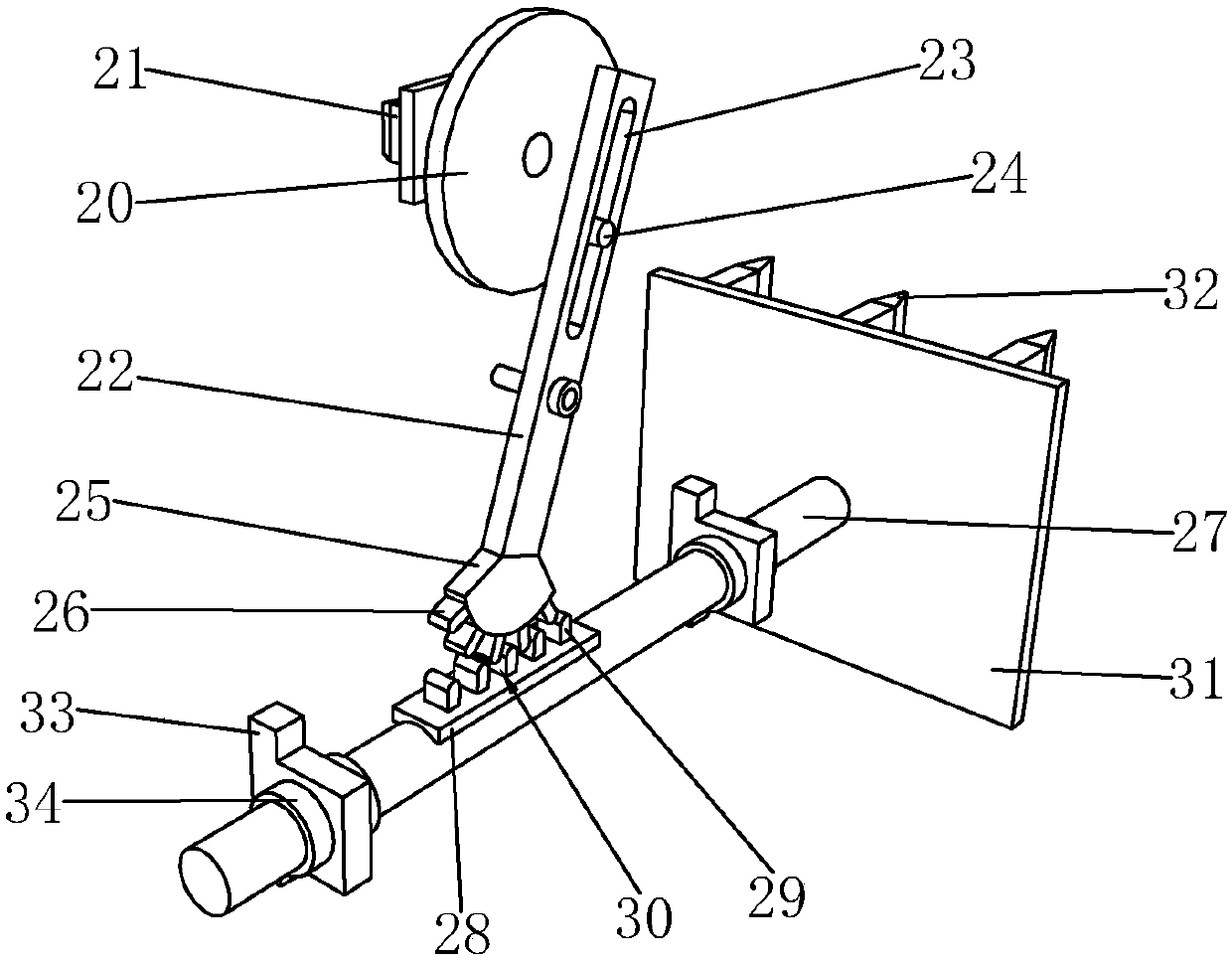

[0025] like Figure 1 to Figure 7 As shown, it is a flattening device for recycling waste cartons according to the present invention, which includes a workbench 1, on which a support frame 2, a fixed bracket 3 and a receiving groove 4 are respectively arranged, and a blanking material is arranged in the receiving groove 4 Through groove 5, feed box 6 is arranged between support frame 2, and feed box 6 comprises feed pipe 7, feed pipe 8 and feed guide pipe 9, and the top of feed pipe 7 is provided with feed inlet 10, feeds The feed pipe 8 is arranged on the feed port 10, the bottom of the feed pipe 7 is provided with a discharge port 11, and the feed pipe 9 is arranged on the discharge port 11, and the feed pipe 9 is positioned above the receiving groove 4, and the feeding Pipe 7 is arranged between support frame 2, and one side of feeding pipe 7 is opening shape, and this side is connected with pusher mechanism 12, and pusher mechanism 12 comprises pusher motor 13, driving lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com