Resource recovery and zero discharge process for treating rare-earth wet-method smelting wastewater

A technology of hydrometallurgy and resource recovery, which is applied in the directions of heating water/sewage treatment, degassed water/sewage treatment, neutralized water/sewage treatment, etc., which can solve the problems of low enthusiasm for enterprise operation, high treatment cost, and long service life of equipment To solve the problem of water pollution, simplify the treatment process and improve the treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

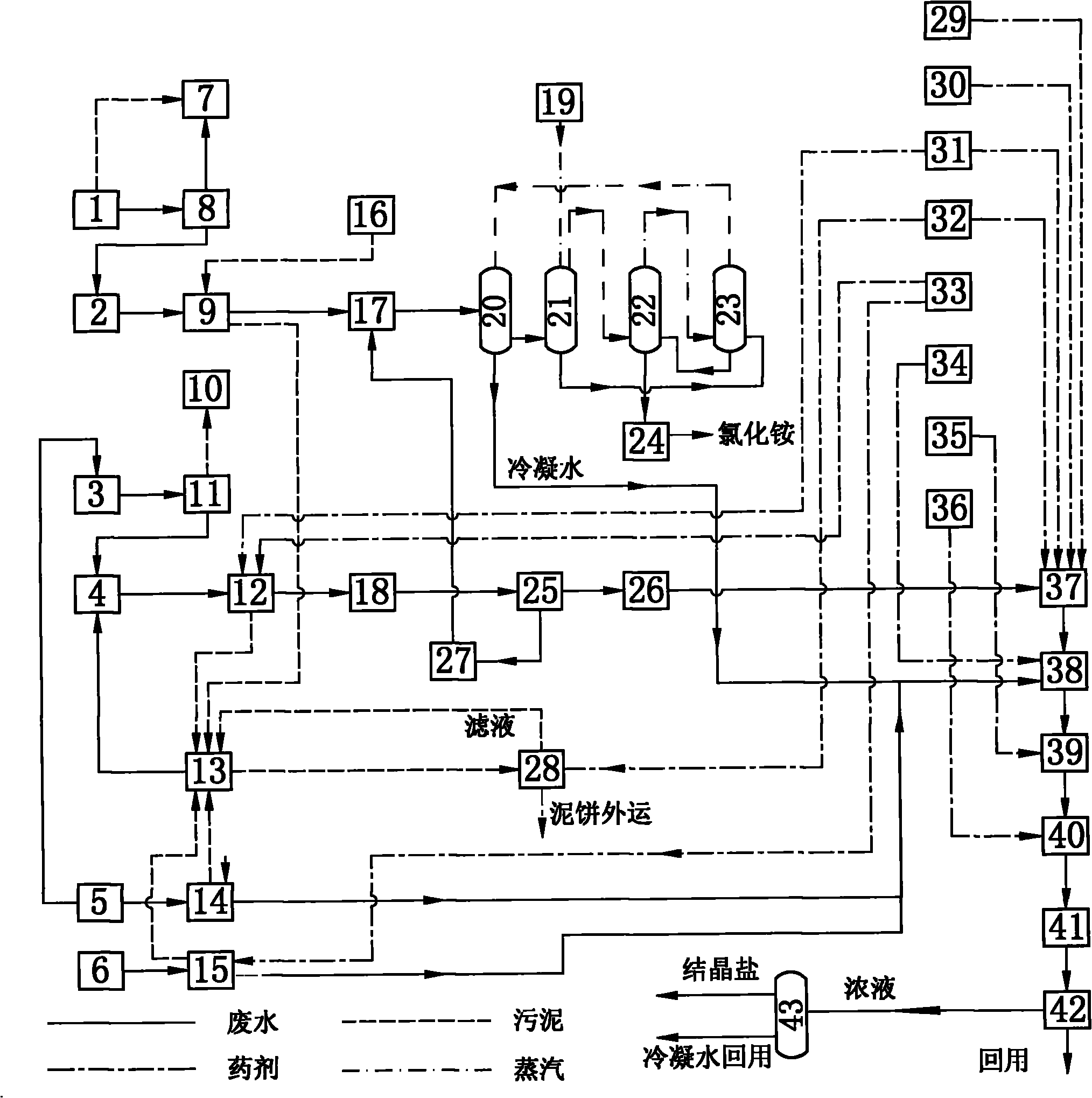

Method used

Image

Examples

Embodiment 1

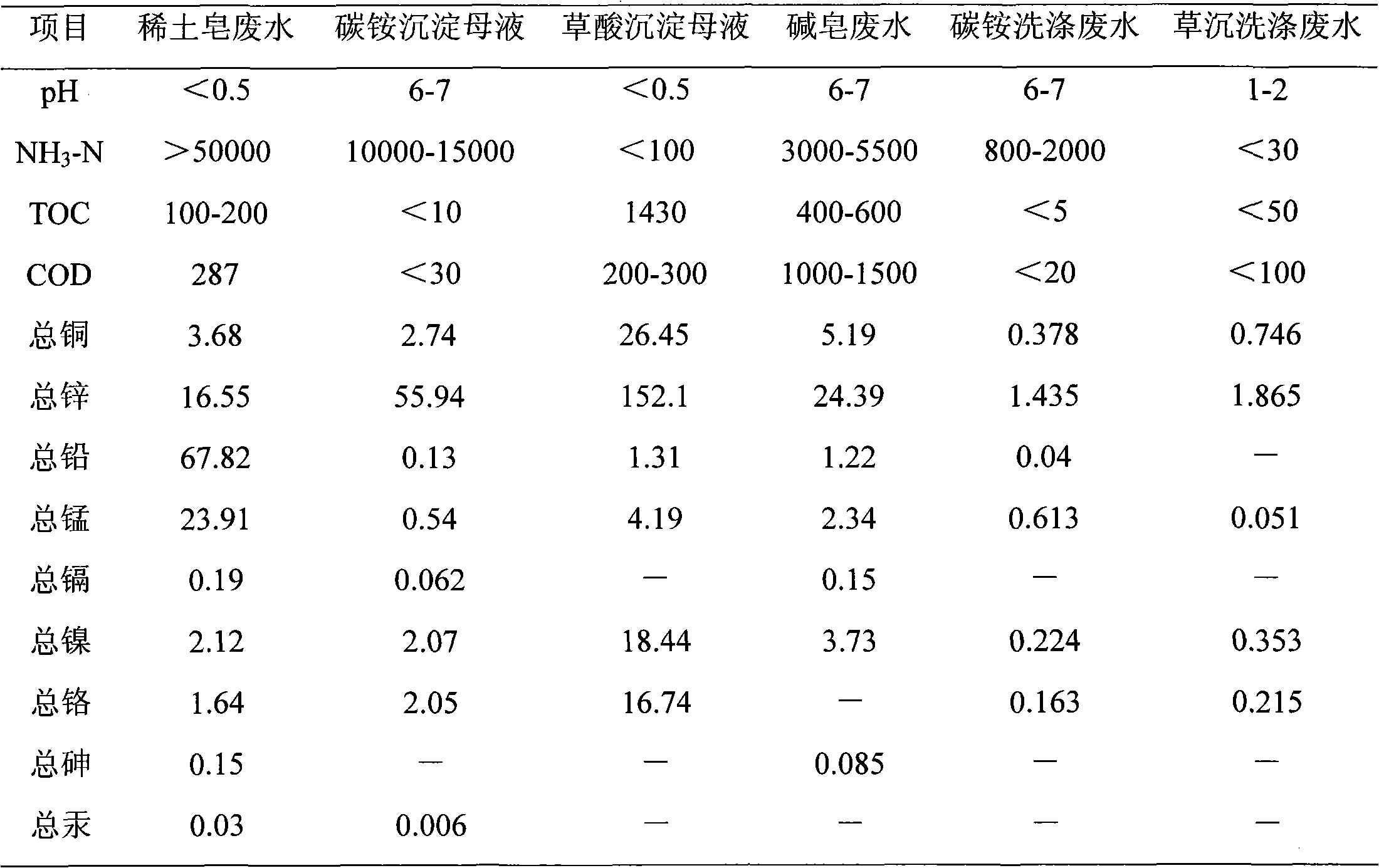

[0035] Taking rare earth soap wastewater, ammonium bicarbonate precipitation mother liquor, oxalic acid precipitation mother liquor, alkali soap wastewater, ammonium bicarbonate washing wastewater and grass sediment washing wastewater as treatment objects in the rare earth wet smelting process, the water quality characteristics are shown in Table 1, and the above 6 Each kind of waste water 2m 3 Process according to the process flow of the present invention.

[0036] Rare earth soap wastewater is first left to stand in the grease trap (1) for 24 hours to collect surface oil and P 507 After reaching oil storage tank 1# (7), take 0.5m 3 / h Niconi pump for dissolved air flotation treatment, collect the floating oil on the surface of the air flotation degreasing tank 1# (8) to the oil storage tank 1# (7), and then discharge the waste water into the ammonium bicarbonate precipitation mother liquor pool (2) and carbon Ammonium precipitation mother liquor mixed. Pump the mixed wast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com