Device for treating waste gas used on production line of scouring pad

A technology for waste gas treatment and production line, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, and the use of liquid separators. Improve the effect of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

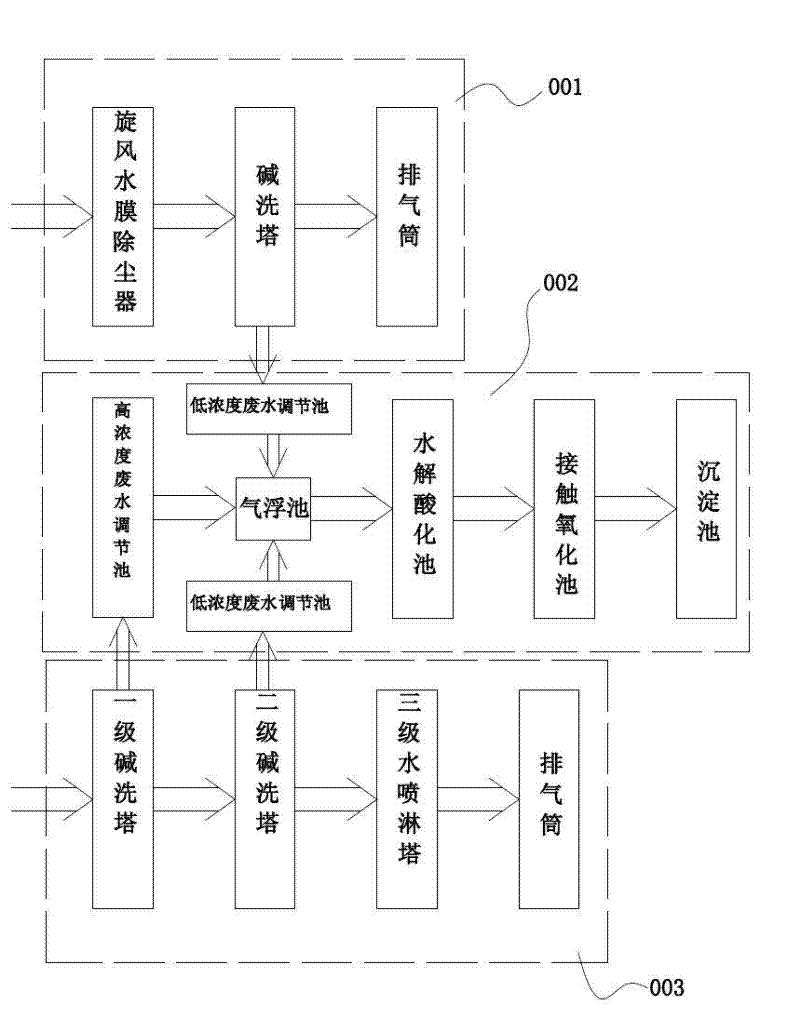

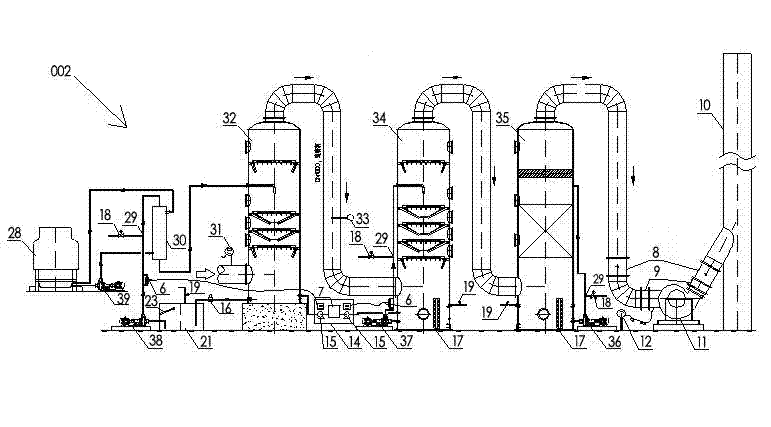

[0026] Embodiment: A waste gas treatment device for a scouring pad production line (see attached figure 1 ), this device is mainly composed of three processing systems, which are the glue spraying waste gas treatment system 001 for treating the waste gas generated in the glue spraying process, the oven waste gas treatment system 003 for treating the waste gas generated in the oven process, and the glue spraying waste gas The waste gas absorption liquid treatment system 002 is used to treat the absorption liquid produced by the treatment system and the oven waste gas treatment system.

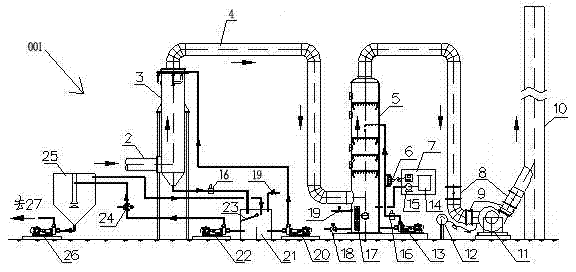

[0027] Glue spray waste gas treatment system (see attached figure 2 ) According to the traveling route of the exhaust gas, there are cyclone water film dust collectors 3, alkali washing towers 5 and exhaust pipes 10 connected in sequence. The front end of the air inlet of the cyclone water film dust collector is connected to the glue spraying room through the air duct 2 to receive the glue spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com