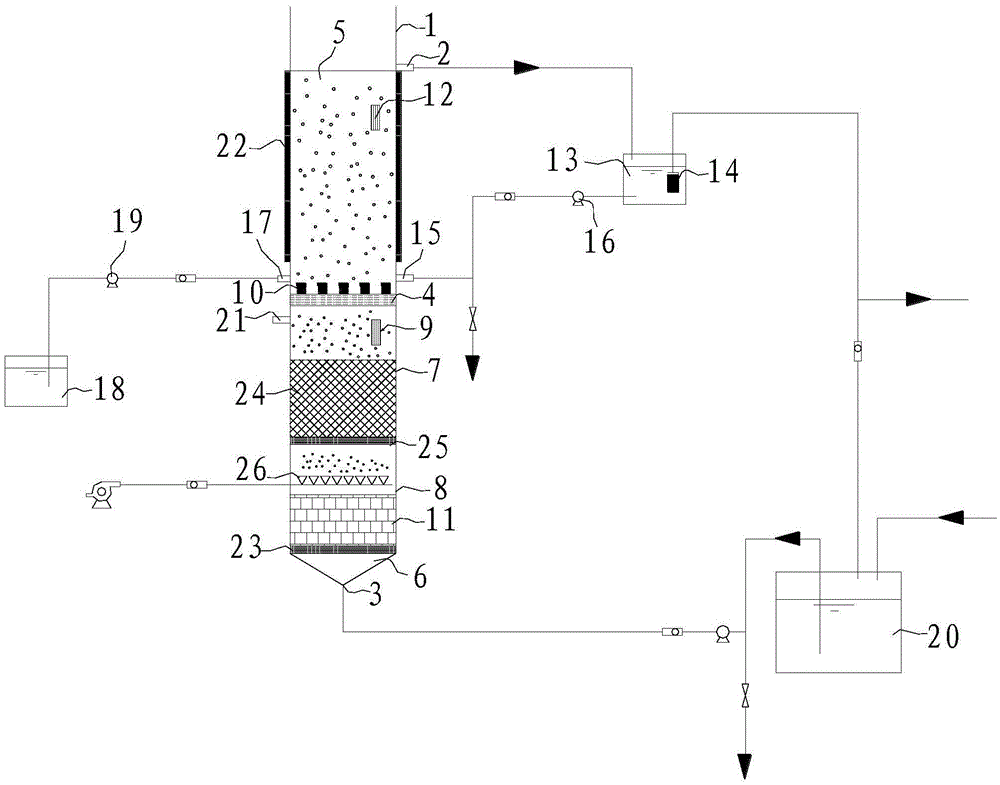

Microalgal culture based biogas liquid treatment device and method

A technology for biogas slurry treatment and microalgae cultivation, applied in enzymatic/microbiology devices, filtration treatment, multi-stage water treatment, etc. Algae utilization efficiency and other issues, to achieve the effect of high value-added comprehensive utilization, harmless and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Taking the pig biogas slurry as the treatment object, the ammonia nitrogen in the biogas slurry is 1073mg / L, the total alkalinity is 5422mg / L, the total phosphorus is 46mg / L, and the COD is 2655mg / L.

[0039] The biogas slurry treatment is carried out in the following steps, the details are as follows:

[0040] (1) After the biogas slurry undergoes natural precipitation and coagulation to remove part of COD, ammonia nitrogen, total phosphorus and large suspended particles, the biogas slurry stock solution is obtained. The biogas slurry stock solution enters the adjustment tank and is diluted 4 times by the effluent of the microalgae concentration device. , enter the biogas slurry treatment device, and control the flow rate of the biogas slurry to 0.3L / h when entering water.

[0041] When the water enters, the ammonia nitrogen in the biogas slurry is 257mg / L, the total alkalinity is 1218mg / L, the total phosphorus is 9mg / L, and the COD is 579mg / L.

[0042] (2) The biogas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com