Cement blending device for hydraulic engineering construction

A water conservancy project and cement technology, which is applied in the field of cement blending devices for water conservancy project construction, can solve problems such as low mixing efficiency and inability to fully mix cement, and achieve the effects of improved processing effect, high promotion and practical value, and novel device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

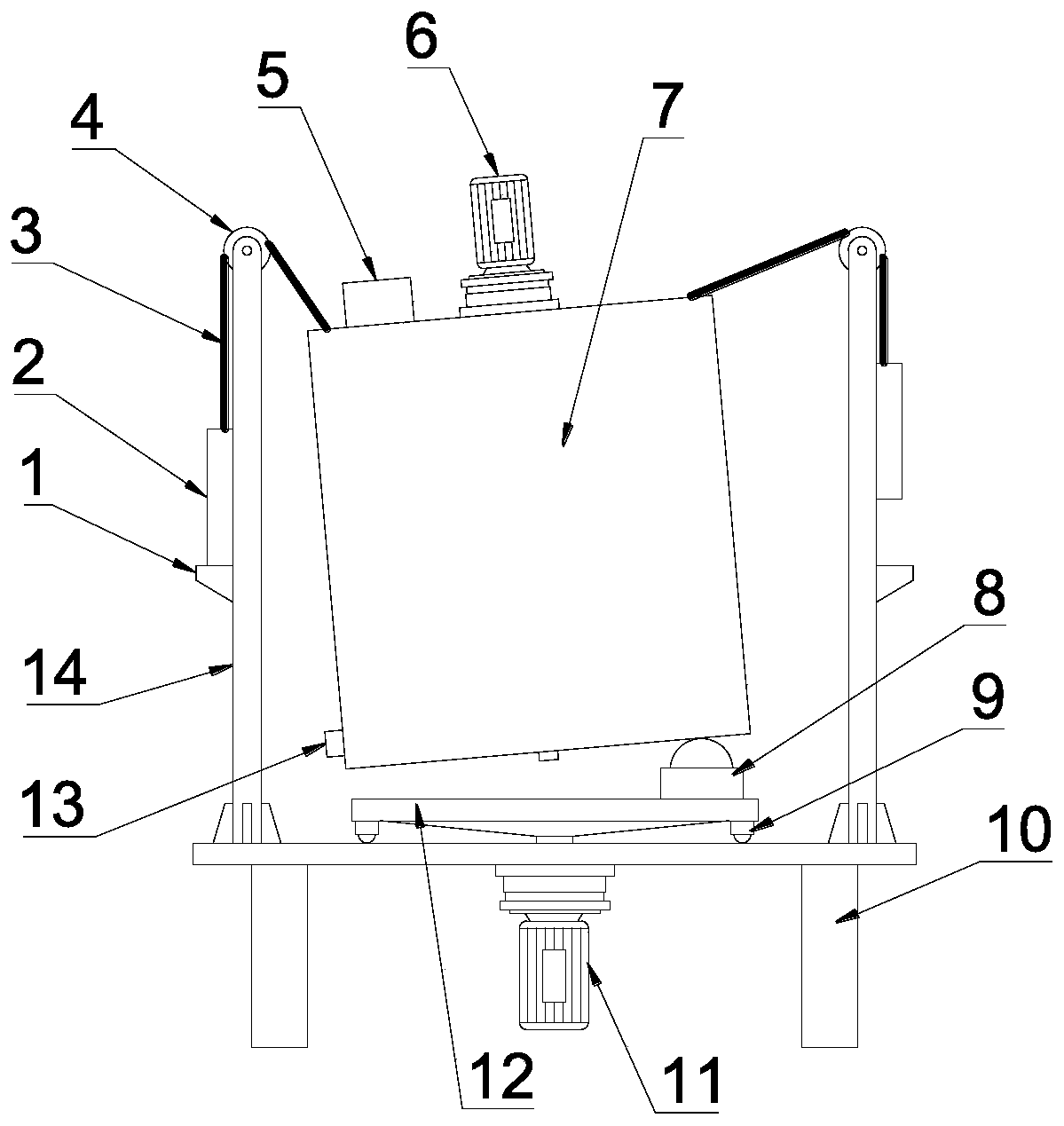

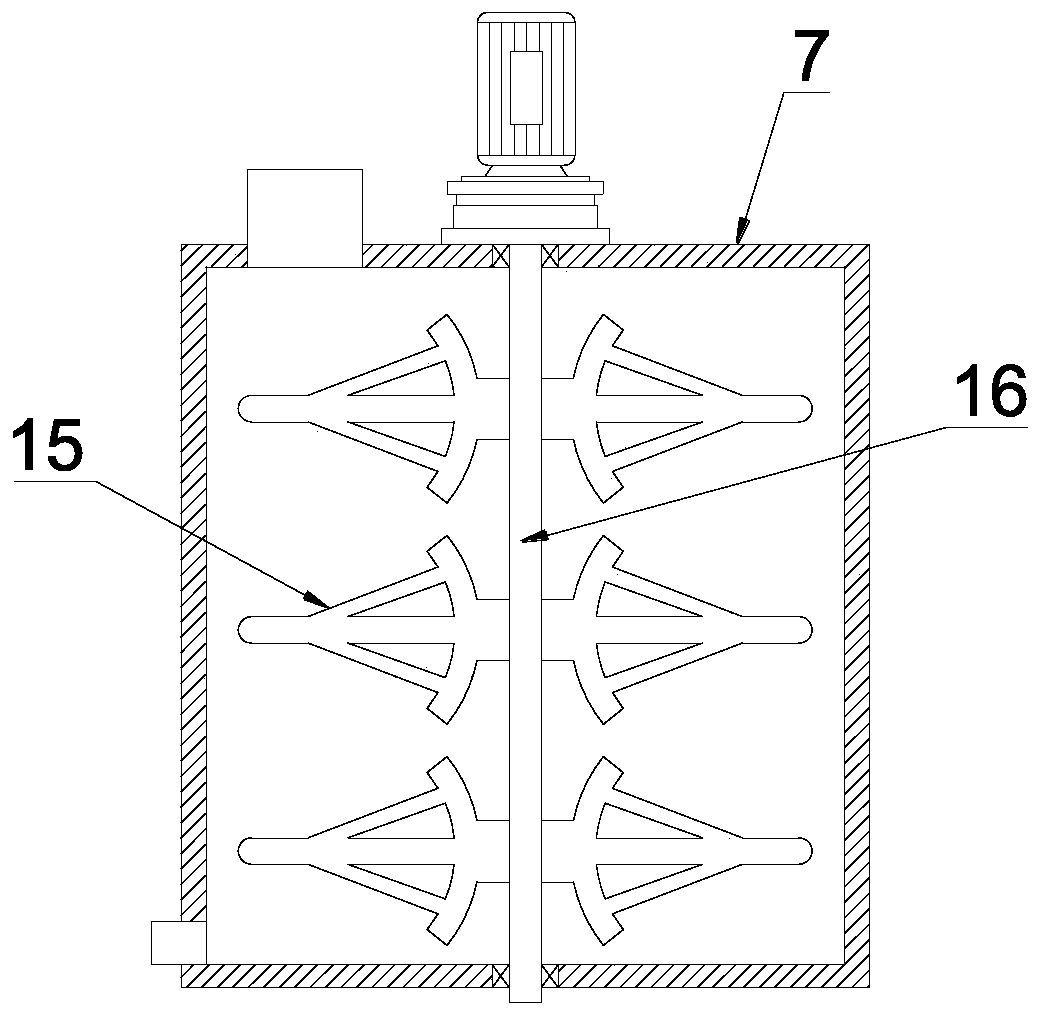

[0027] see Figure 1~3 , in an embodiment of the present invention, a cement blending device for water conservancy construction, comprising a blending box 7, a frame 10 and a column 14, the blending box 7 is a cylindrical cylinder structure with both ends sealed, and the top of the blending box 7 There is a material inlet 5, and the side bottom of the mixing box 7 is provided with a material outlet 13, the material inlet 5 and the material outlet 13 are respectively used for feeding and discharging, and the middle part of the mixing box 7 is provided with a stirring shaft 16 , the top and the bottom of the stirring shaft 16 and the mixing box 7 are sealed and rotated, and the top of the mixing box 7 is also provided with a first drive mechanism 6 for driving the stirring shaft 16 to rotate. A number of stirring assemblies 15 are installed on the shaft 16, and the first driving mechanism 6 can drive the stirring shaft 16 to rotate, and then drive the stirring assemblies 15 to r...

Embodiment 2

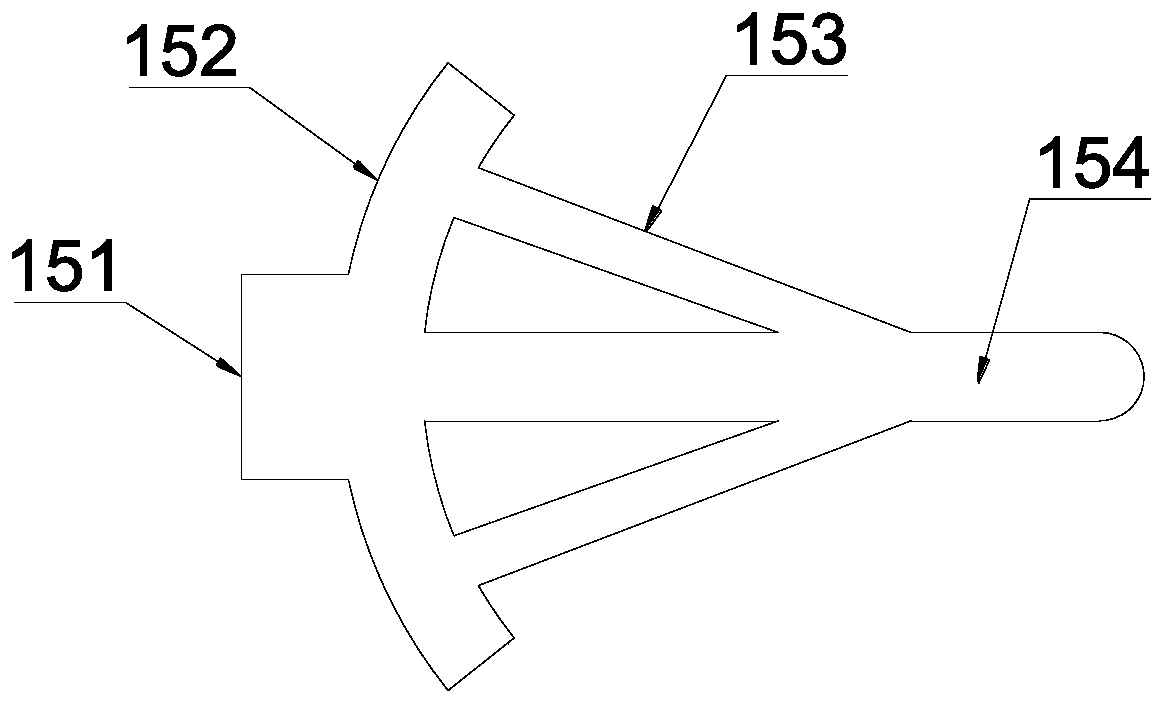

[0035] see figure 2 and 3 The difference between this embodiment and Embodiment 1 is that the stirring assembly 15 includes a fixing seat 151, an arc bar 152, a slanting bar 153 and a cross bar 154, and one side of the fixing seat 151 is fixed to the stirring shaft 16 On, the other side of fixed seat 151 is provided with arc-shaped bar 152, and arc-shaped bar 152 is the arc-shaped structure that both ends are away from stirring shaft 16, and the inner middle part of arc-shaped bar 152 is provided with cross bar 154, and the cross bar 154 The upper and lower sides are respectively provided with oblique rods 153, one end of the oblique rod 153 is fixed on the cross bar 154, the other end of the oblique rod 153 is fixed on the arc rod 152, and the distance between the oblique rod 153 and the cross rod 154 is 15-30 ° included angle, the fixed seat 151, the arc bar 152, the oblique bar 153 and the cross bar 154 are integrally processed and formed, and the structure setting of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com