Method and device for enhanced ozone oxidation wastewater treatment of ozone tail gas

An ozone oxidation and treatment device technology, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of exhaust gas damage and poor effect, and achieve the effect of strengthening the treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The object of advanced treatment is coking wastewater after biological treatment, and the COD is about 150mg / L.

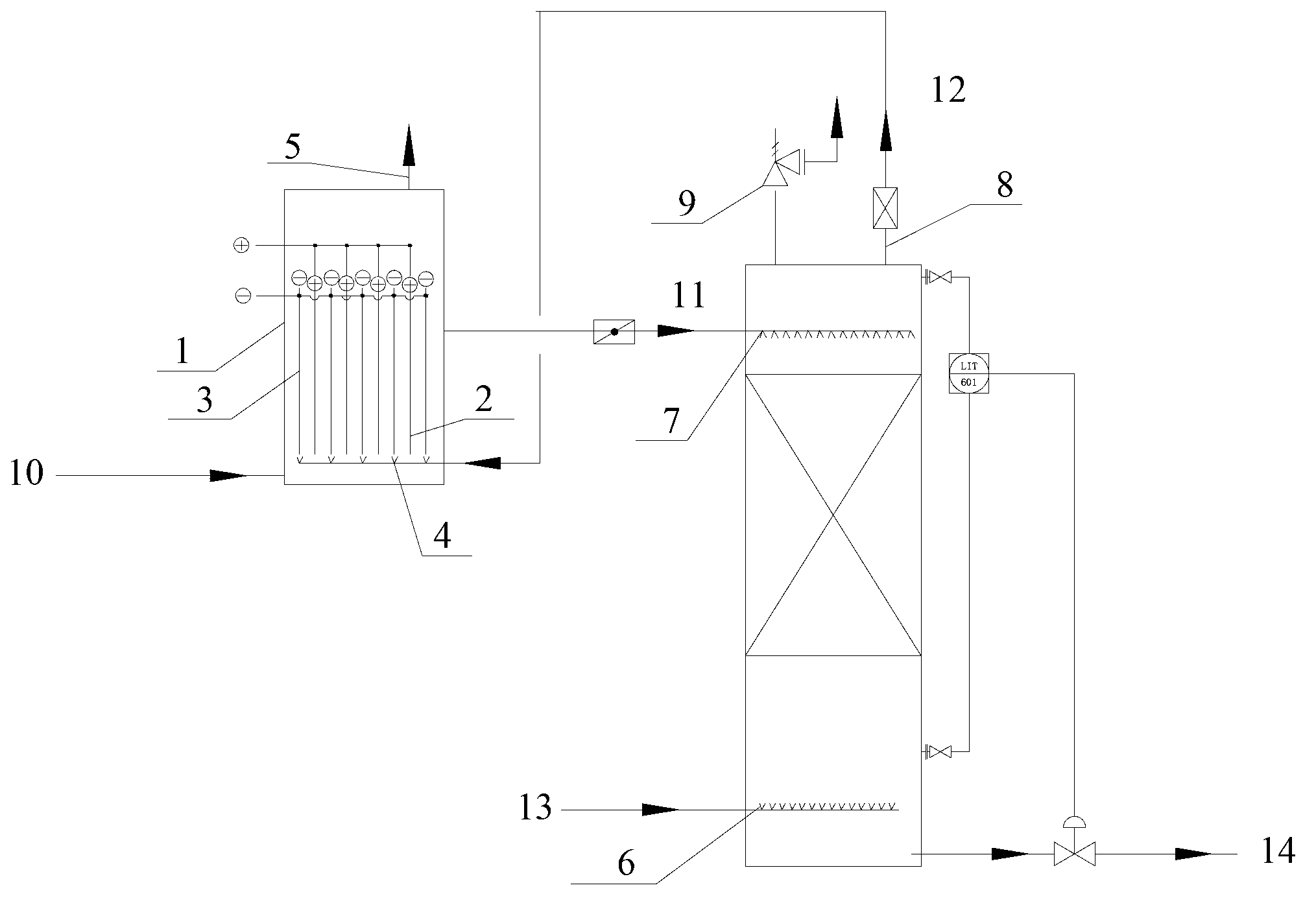

[0047] The waste water 10 first enters the pre-electrolysis unit for electrolysis reaction, and the electrolysis voltage is controlled to be 2V. The ozone tail gas 12 generated by the subsequent ozone reaction is simultaneously passed into the electrocatalytic reactor. The anode 2 uses a titanium-based ruthenium dioxide plate, and the cathode 3 is graphite felt. The aeration device 4 is a pure titanium aeration head. The wastewater 11 (containing hydrogen peroxide) after the electrolysis reaction is pumped into the ozone oxidation unit, and the ozone 13 is passed into the ozone oxidation reactor for reaction. The ozone 13 is ozone generated by an oxygen source, and the amount of ozone added is 100mg / L. The ozone tail gas 12 produced by the ozone oxidation unit is connected to the aeration device 4 in the pre-electrolysis unit. Finally, the effluent 14 of th...

Embodiment 2

[0049] The object of advanced treatment is the biologically treated wastewater from the production of zimycin, with a COD of about 300mg / L.

[0050] Wastewater 10 first enters the pre-electrolysis unit for electrolysis reaction, and the electrolysis voltage is controlled to 7V. The ozone tail gas 12 generated by the subsequent ozone reaction is simultaneously passed into the electrocatalytic reactor. The anode 2 is made of titanium-based titanium dioxide plate, and the cathode 3 is activated carbon and polytetrafluoroethylene. The powder electrode formed by bonding and pressing ethylene emulsion, and the aeration device 4 is a pure titanium aeration head. The wastewater 11 (containing hydrogen peroxide) after the electrolysis reaction is pumped into the ozone oxidation unit, and the ozone 13 is passed into the ozone oxidation reactor for reaction. The ozone 13 is ozone generated by an oxygen source, and the amount of ozone added is 200mg / L. The ozone tail gas 12 produced by th...

Embodiment 3

[0052] The object of advanced treatment is printing and dyeing wastewater after biological treatment, and the COD is about 250mg / L.

[0053] Waste water 10 first enters the pre-electrolysis unit for electrolysis reaction, and the electrolysis voltage is controlled to 4V. The ozone tail gas 12 generated by the subsequent ozone reaction is simultaneously passed into the electrocatalytic reactor. The anode 2 is made of titanium-based titanium dioxide plate, and the cathode 3 is activated carbon fiber. Device 4 is a silica gel aeration head. The wastewater 11 (containing hydrogen peroxide) after the electrolysis reaction is pumped into the ozone oxidation unit, and the ozone 13 is passed into the ozone oxidation reactor for reaction. The ozone 13 is ozone generated by an oxygen source, and the amount of ozone added is 150mg / L. The ozone tail gas 12 produced by the ozone oxidation unit is connected to the aeration device 4 in the pre-electrolysis unit. Finally, the effluent 14 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com