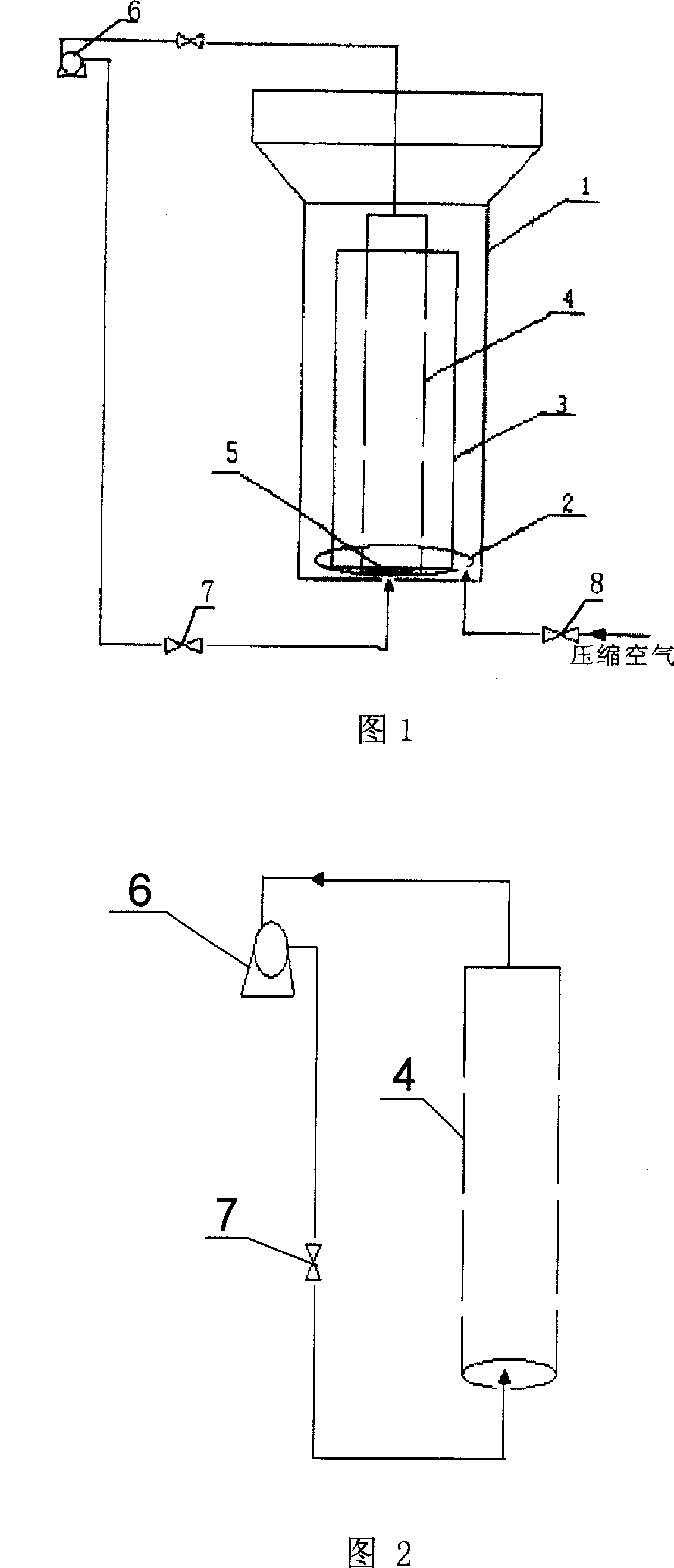

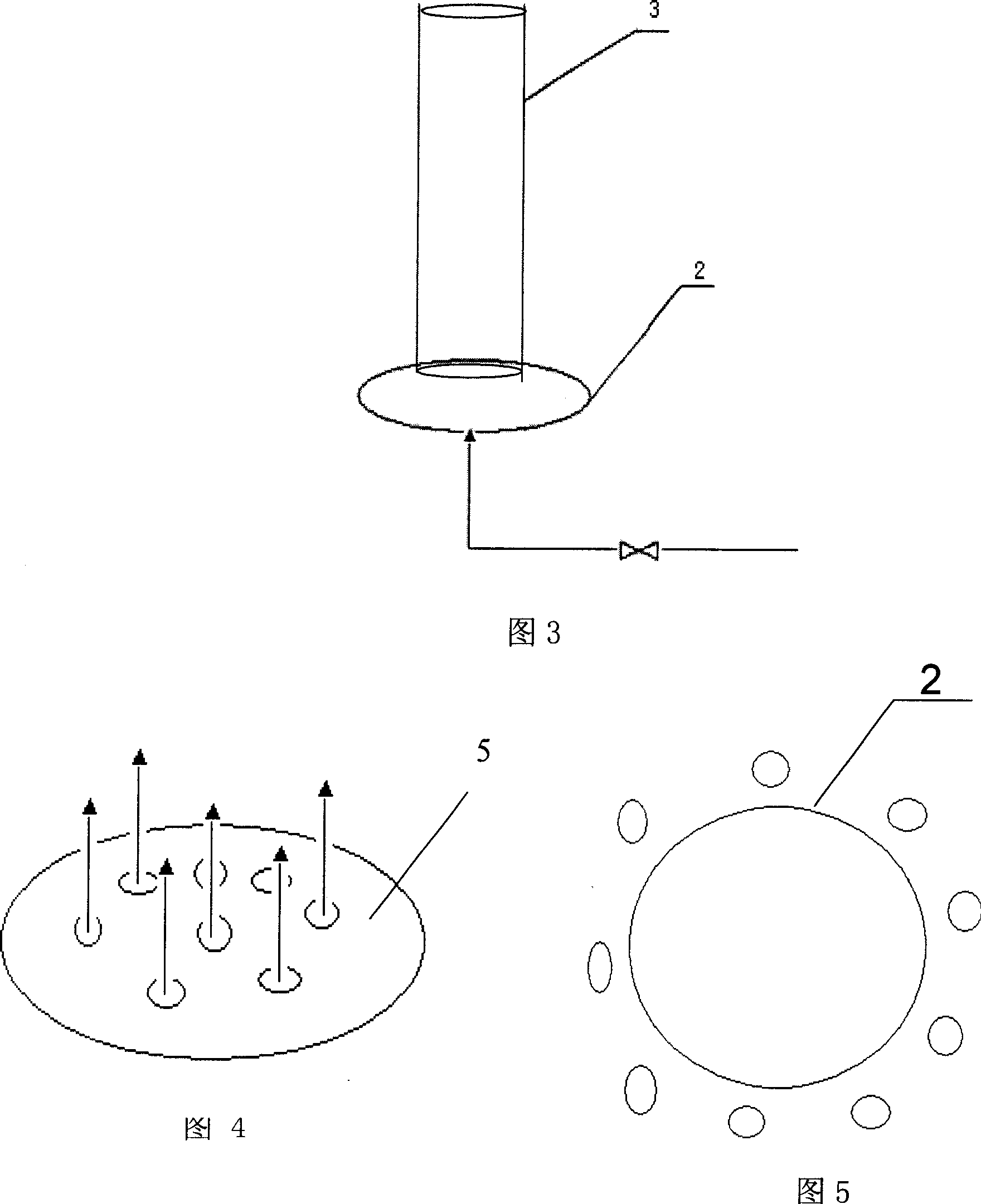

Anaerobic and aerobic coupled pneumatic lift type circulation biochemical reactor, and method for treating wastewater of chemical fiber

A biochemical reactor, anaerobic and aerobic technology, applied in the field of biochemical technology and environmental protection, can solve the problems of poor COD degradation effect, high cost of wastewater treatment, poor mass transfer effect, etc., to achieve low cost of wastewater treatment and high efficiency Good, easy-to-make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The raw material of chemical fiber wastewater is added to a new type of anaerobic-aerobic coupled air-lift loop reactor for biochemical treatment. At ventilation volume 0.3m 3 .h -1 , exhaust gas circulation volume 0.2m 3 .h -1 , the exhaust gas circulation interval is 4 hours, the temperature is 20°C, the pH is 8.5, and the time is 10 hours, the COD of the wastewater is reduced to 93mg.l -1 .

Embodiment 2

[0034] The raw material of chemical fiber wastewater is added to a new type of anaerobic-aerobic coupled air-lift loop reactor for biochemical treatment. At ventilation volume 0.25m 3 .h -1 , Exhaust gas circulation volume 0.3m 3 .h -1 , the exhaust gas circulation interval is 2 hours, the temperature is 25°C, the pH is 8.0, the treatment is 12 hours, and the COD of the wastewater is reduced to 100mg.l -1 .

Embodiment 3

[0036] The raw material of chemical fiber wastewater is added to a new type of anaerobic-aerobic coupled air-lift loop reactor for biochemical treatment. At ventilation volume 1.5m 3 .h -1 , Exhaust gas circulation volume 2.0m 3 .h -1 , the exhaust gas circulation interval is 6 hours, the temperature is 30°C, and the pH is 7.5. After 8 hours of treatment, the COD of wastewater is reduced to 73mg.l -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com