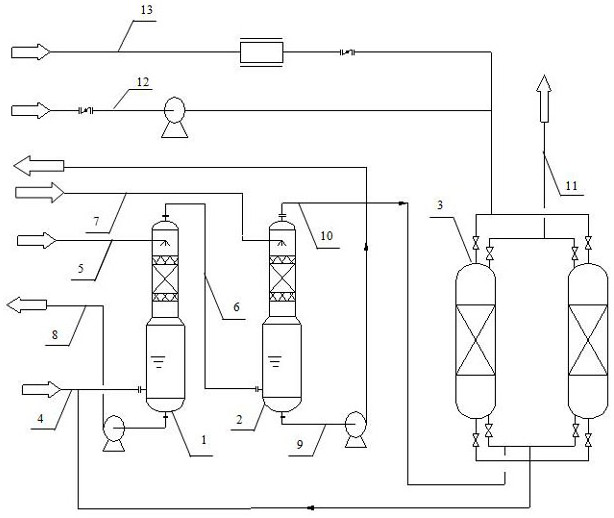

Refinery VOCs absorption and adsorption coupling treatment device and method

A treatment method and technology of treatment device, which are applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of shortened operation period of adsorbent, poor absorption performance, and low limit of emission requirements, and achieve improved absorption treatment. effect, absorption efficiency improvement, selectivity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] An adsorbent used in the adsorption tank of the present invention was prepared.

[0052] Take 100g of petroleum coke, dry it at -300kPa, 100°C for 5h, mix it with 300g of potassium hydroxide and 10g of copper hydroxide, and activate it at 900°C for 0.4h in a nitrogen atmosphere.

[0053] The sample was cooled, ground into powder, added to a 10wt% hydrochloric acid solution for washing until the pH of the filtrate was neutral, and then dried at 150°C for 6 hours to obtain an intermediate product of activated carbon.

[0054] Take 40 g of activated carbon intermediate product, use 100 g of nitric acid solution with a concentration of 4 mol / L to carry out surface oxidation modification, use supersaturated impregnation for 24 h, filter out the solid, and dry at 120 °C for 4 h. The dried activated carbon was treated for 12 hours at a temperature of 400°C under a nitrogen atmosphere, and it was recorded as Adsorbent A. The specific surface area of adsorbent A is 2716 m 2 ...

Embodiment 2

[0056] Take 100g of petroleum coke, dry it at -300kPa, 100°C for 5h, mix it with 200g of potassium hydroxide and 4g of copper hydroxide, and activate it at 700°C for 0.3h under a nitrogen atmosphere.

[0057] The sample was cooled, ground into powder, added to a 10wt% hydrochloric acid solution for washing until the pH of the filtrate was neutral, and then dried at 150°C for 6 hours to obtain an intermediate product of activated carbon.

[0058] Take 40g of activated carbon intermediate product, use 100g of nitric acid solution with a concentration of 8 mol / L to carry out surface oxidation modification, use supersaturated impregnation for 24 h, filter out the solid, and dry at 120 °C for 4 h. The dried activated carbon was treated for 12 hours at a temperature of 400°C under a nitrogen atmosphere, and it was designated as adsorbent B. The specific surface area of adsorbent B is 1716 m 2 / g, the pore volume is 0.85cm 3 / g; the iodine adsorption value is 1597 mg / g, and the C...

Embodiment 3

[0060] Gasoline oxidative sweetening tail gas and liquid hydrocarbon oxidative sweetening tail gas of a refining and chemical enterprise, the total hydrocarbon concentration is 2.6×10 5 mg / m 3 , the organic sulfide concentration is 5380 mg / m 3 , the concentration of benzene series is 1.31×10 4 mg / m 3 .

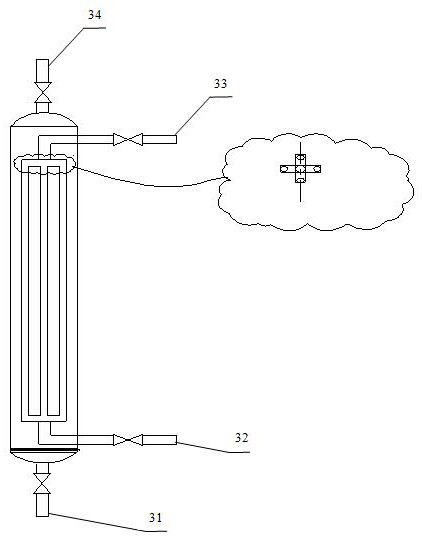

[0061] The exhaust gas first enters the first absorption tower I for countercurrent contact absorption, the absorbent is catalytic cracked gasoline for absorption, and then enters the second absorption tower II for countercurrent contact absorption, the absorbent is diesel distillate, and the absorbed liquid-gas ratio is 100L / m 3 , the absorption temperature is 30°C, the absorption pressure is 100kPa, and then it enters the adsorption tank for normal temperature and pressure adsorption. Two adsorption tanks are set up for adsorption regeneration alternately. The adsorption tank is filled with adsorbent A. Attached treatment, the heat medium is introduced into the collecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com