Boiling heat transfer device of electronic component

A technology of electronic components and boiling heat transfer, which is applied in the field of boiling phase change heat transfer research, can solve the problems of deterioration of heat transfer on the surface of heating components, reduction of rewetting ability of heating wall surface, reduction of capillary action of channel size, etc., to achieve The effect of increasing the enhanced heat transfer surface area, small specific gravity, and increasing the critical heat flux value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the drawings and examples.

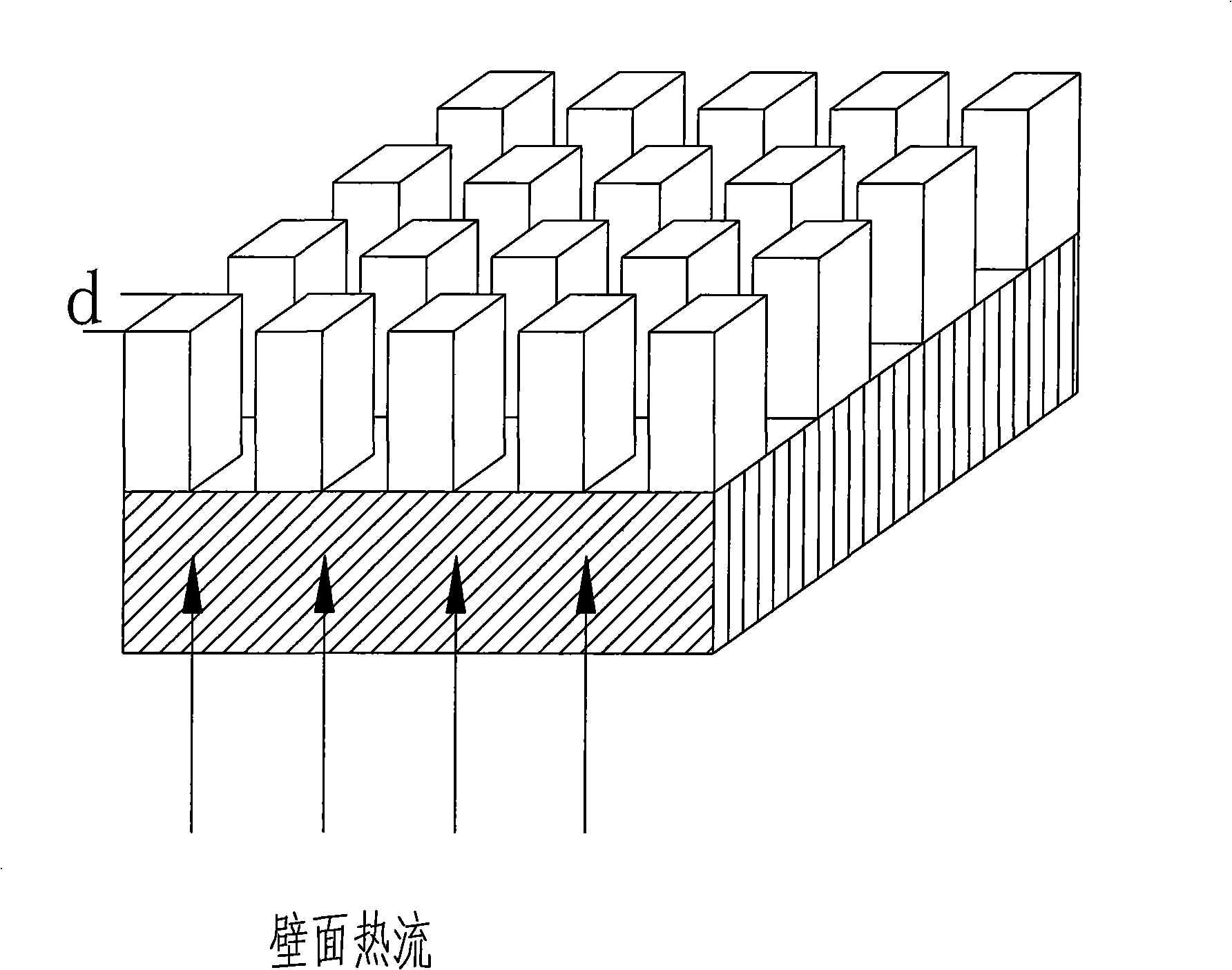

[0020] refer to figure 1 , the boiling heat exchange device for electronic components of the present invention includes: a heat dissipation plate fixed on the surface of the electronic components, a metal foam layer is sintered on the heat dissipation plate, and a square column microstructure with a width d of 50 μm to 200 μm is provided on the metal foam , the mutual spacing of the square column microstructures is 50 μm to 200 μm; wherein, the metal foam layer is a copper foam layer or an aluminum foam layer, the heat dissipation plate is a copper plate or an aluminum plate, and the heat dissipation plate is bonded to the surface of the electronic component through insulating and heat-conducting silica gel.

[0021] The opening of the square column microstructure is realized by laser marking technology. Laser marking t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com