Composite wick type special-shaped heat pipe radiator

A heat pipe radiator and liquid-absorbing core technology, applied in indirect heat exchangers, lighting and heating equipment, cooling/ventilation/heating transformation, etc., can solve the problems of low heat dissipation efficiency, slow return speed, large radiator wind resistance, etc. Achieve the effects of improving heat dissipation efficiency, reducing wind resistance, and increasing heat dissipation surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

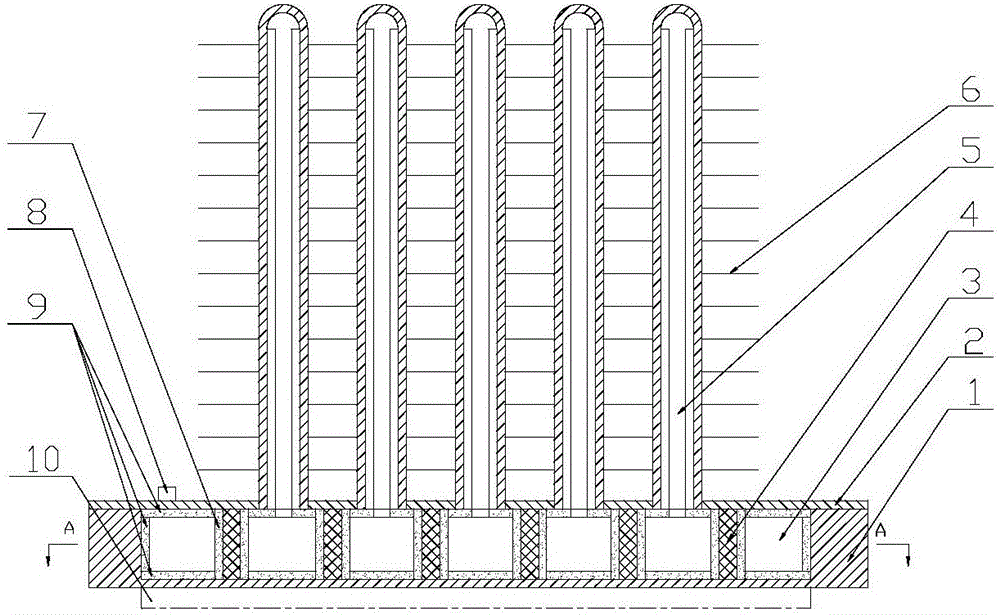

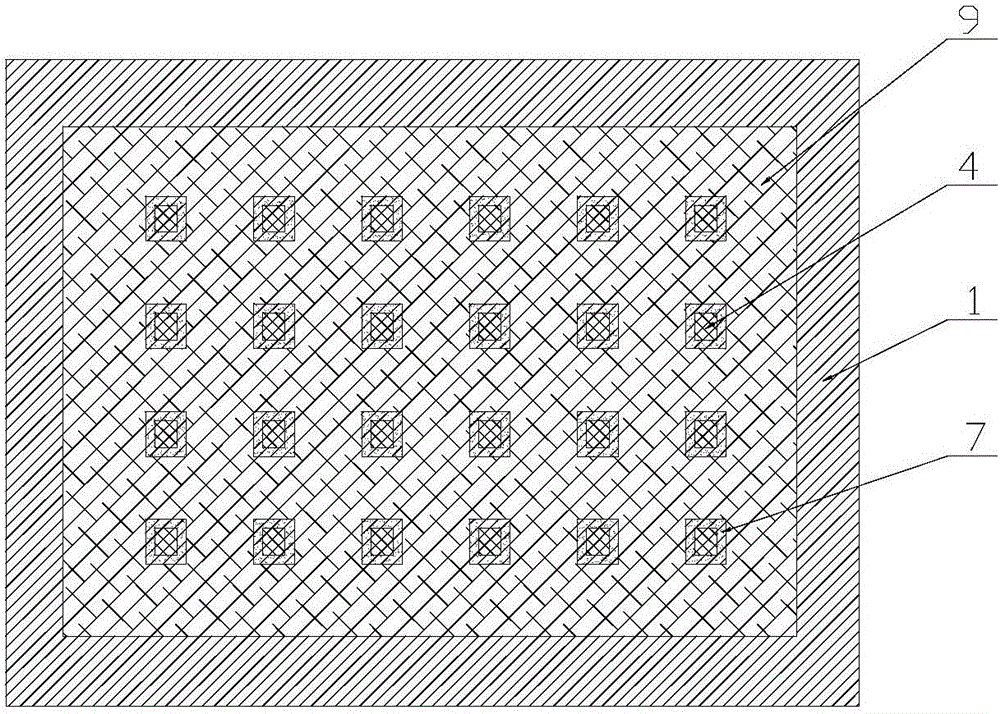

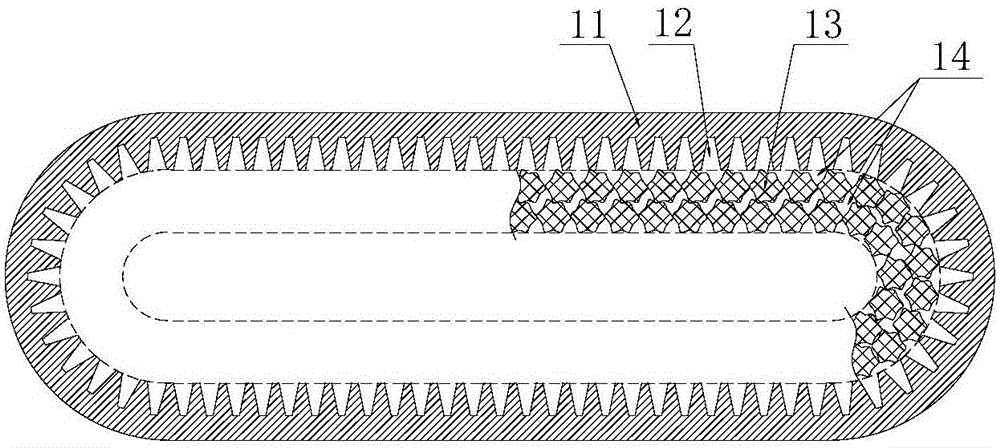

[0025] Such as Figure 1 to Figure 3 As shown, a compound liquid-absorbing core type special-shaped heat pipe radiator includes a substrate 1, a special-shaped heat pipe 5 and heat dissipation fins 6 arranged on the outside of the heat pipe 5, the inside of the substrate 1 is provided with an evaporation chamber 3, and the bottom of the substrate 1 The surface is a heat-absorbing surface, that is, the installation surface of the heat source module. The heat pipe 5 includes a heat pipe body 11 with a special-shaped cross section. Grooves 12 are arranged on the inner wall of the heat pipe body 11, and protrusions are formed between adjacent grooves 12. , the inner wall of the heat pipe main body 11 is laid with velvet fin fiber layer I13, the inner space of the heat pipe 5 communicates with the evaporation chamber 3, and the inner space of the heat pipe 5 and the evaporation chamber 3 jointly form a closed phase change hot chamber. The special-shaped heat pipe refers to a heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber diameter | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com