Sub-control phase change heat transfer system and sub-control phase change heat transfer method

A phase-change heat and controller technology, applied to indirect heat exchangers, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of limited emptying capacity, poor adjustment characteristics, and large control hysteresis, and achieve improved Reliability and precision, flexible layout design, and improved adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

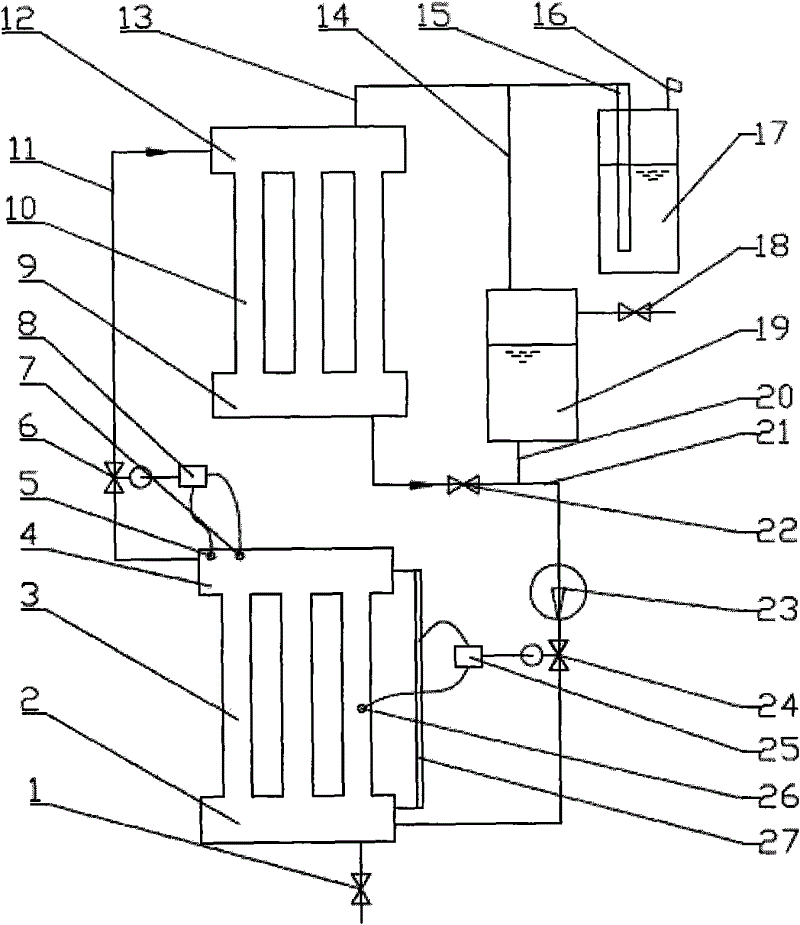

[0040] An embodiment of the split-controlled phase-change heat system of the present invention is as attached figure 1 As shown, the main components include: liquid discharge valve 1; heat-absorbing lower header 2; heat-absorbing tube bundle 3; heat-absorbing upper header 4; gas pressure sensor 5; airflow regulating valve 6; gas temperature sensor 7; airflow regulating valve Controller 8; exothermic lower header 9; exothermic tube bundle 10; steam pipe 11; exothermic upper header 12; breathing pipe 13; gas side connecting pipe 14 of liquid storage tank 19; Liquid seal box 17; rehydration valve 18; liquid storage tank 19; liquid side communication pipe 20 of liquid storage tank 19; condensate pipe 21; discharge valve 22; pump 23; liquid flow regulating valve 24; liquid flow regulating valve controller 25 ; Wall temperature sensor 26; Liquid level sensor 27.

[0041] In this embodiment, the heat-absorbing device includes a heat-absorbing upper header 4, a heat-absorbing lower h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com