Movable heat storage and discharge device based on pulsating heat pipes and heat storage and discharge method thereof

A pulsating heat pipe, heat storage and discharge technology, applied in heat storage equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problem of no heat storage link, etc., to achieve stable and reliable operation, high heat energy flux density, and stable temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

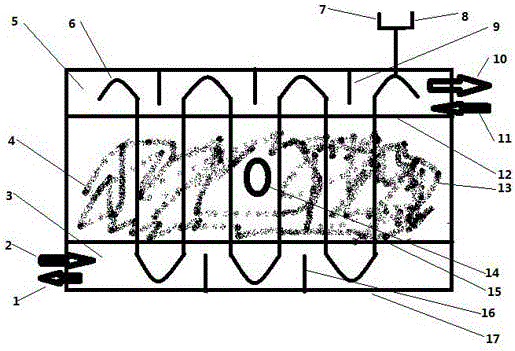

[0028] The technical scheme of the present invention will be further described in detail below in conjunction with the drawings and embodiments.

[0029] When considered in conjunction with the drawings, the present invention can be understood more completely and better. The drawings described here are used to provide a further understanding of the present invention, and the embodiments and descriptions thereof are used to explain the present invention and do not constitute an improper limitation of the present invention.

[0030] Figure 1 is a schematic structural diagram of a pulsating heat pipe heat storage device of the present invention; figure 1 Names of parts: 1. Heating fluid inlet, 2. Heating fluid outlet, 3. Heating chamber, 4. Phase change material chamber, 5. Cooling chamber, 6. Pulsating heat pipe, 7. Pulsating heat pipe, vacuum filling Quality interface, 8. Pulsating heat pipe pressure gauge interface, 9. Cooling fluid deflector in the cooling chamber, 10, Cooling fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com