Solar medium-high-temperature loop heat pipe steam generator

A technology of a steam generator and a loop heat pipe, which is applied in the field of solar thermal utilization, can solve the problems of limited heat transfer performance, poor heat transfer performance, restrictions, etc., so as to improve stability and reliability, reduce system costs, and improve reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

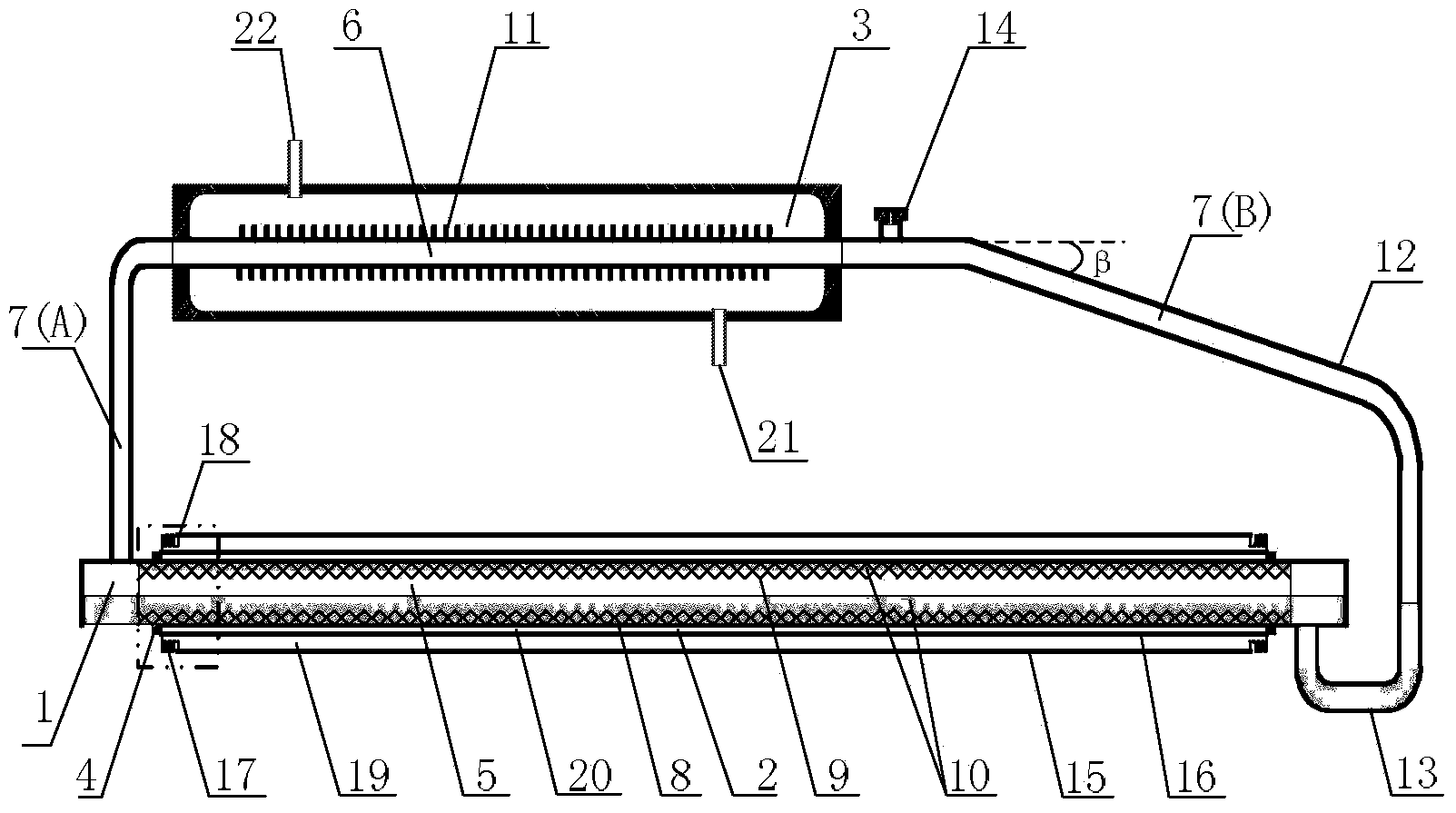

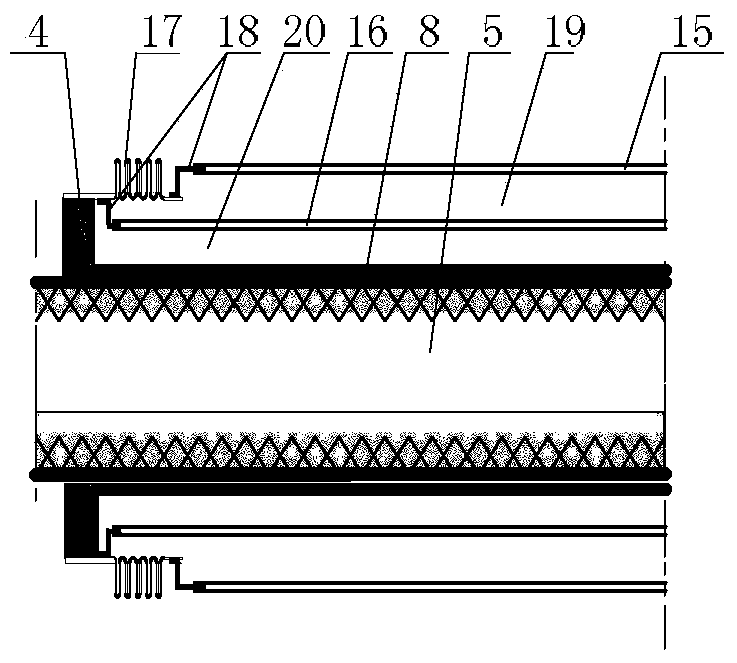

[0032] Such as figure 1 and figure 2As shown, the present invention discloses a solar medium and high temperature loop heat pipe steam generator: it is composed of a loop heat pipe 1, a straight-through all-glass vacuum tube 2, a steam drum 3 and a sealing ring 4; the loop heat pipe 1 is composed of A closed loop composed of evaporating section 5, condensing section 6, first adiabatic section 7(A) and second adiabatic section 7(B); the outer surface of the evaporating section 5 tube is coated with selective absorption coating 8, and the inner wall of the tube is filled with metal Liquid-absorbing core 9, the tube is equipped with heat transfer medium 10; the condensation section 6 is wrapped with metal fins 11; the first adiabatic section 7 (A) is a steam rising pipe, and the second adiabatic section 7 (B) is descended by condensate Pipe 12, U-shaped liquid storage pipe 13 and exhaust valve 14; one end of the first adiabatic section 7 (A) is sealed to the top of one side of ...

Embodiment 2

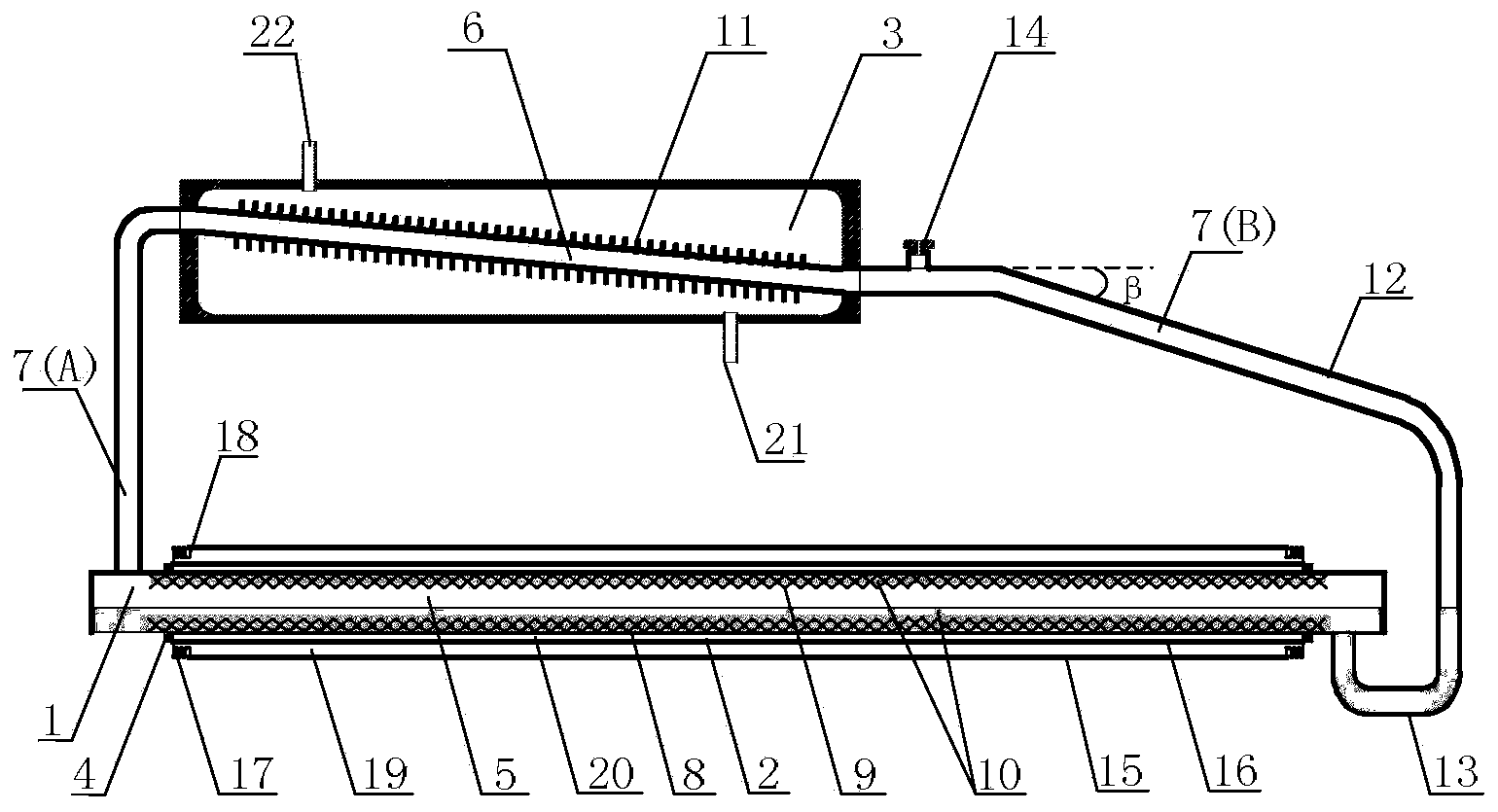

[0035] image 3 Shown is a schematic structural diagram of the solar medium-high temperature loop heat pipe steam generator of this embodiment.

[0036] The structural form and some materials of this embodiment are the same as those of Embodiment 1. The difference is: the material of the loop heat pipe 1 is carbon steel, the diameter of the evaporation section 5 is 100mm, and the length is 4060mm; the length of the condensation section 6 is 3000mm; the height of the center line of the evaporation section 5 and the condensation section 6 is 800mm; the condensate drops The length of the horizontal section of the tube 12 is 100 mm, and the angle β between the inclined section and the horizontal section is 30°; the centerline width of the U-shaped liquid storage tube 13 is 200 mm. The selective absorption coating 8 on the outer surface of the tube in the evaporation section 5 is Ag-Cr 2 o 3 The material has an absorption rate of 96% and an emissivity of 14% under non-vacuum con...

Embodiment 3

[0039] Figure 4 Shown is a schematic structural diagram of the solar medium-high temperature loop heat pipe steam generator of this embodiment. The structural forms, some materials and structural parameters involved in this embodiment are the same as those in Embodiment 1. The difference is that the length of the evaporation section 5 of the loop heat pipe 1 is 2000mm; the diameter of the condensation section 6 is 40mm and the length is 1600mm; The diameter of the condensate downcomer 12 is 40mm; the length of the horizontal section of the condensate downcomer 12 is 70mm, and the angle β between the inclined section and the horizontal section is 10°; the width of the center line of the U-shaped liquid storage pipe 13 is 100mm. The selective absorption coating 8 on the outer surface of the tube in the evaporation section 5 is Ni-SiO 2 The material has an absorption rate of 86% and an emissivity of 4% under non-vacuum conditions; the metal liquid-absorbing core 9 filled in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com