Semiconductor temperature difference power generation system

A technology of thermoelectric power generation and thermoelectric power generation modules, which is applied in the direction of generators/motors, electrical components, engine components, etc., can solve the problems of single working fluid and low system efficiency, and achieve small loss of useful energy, energy saving, and reduction of temperature difference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

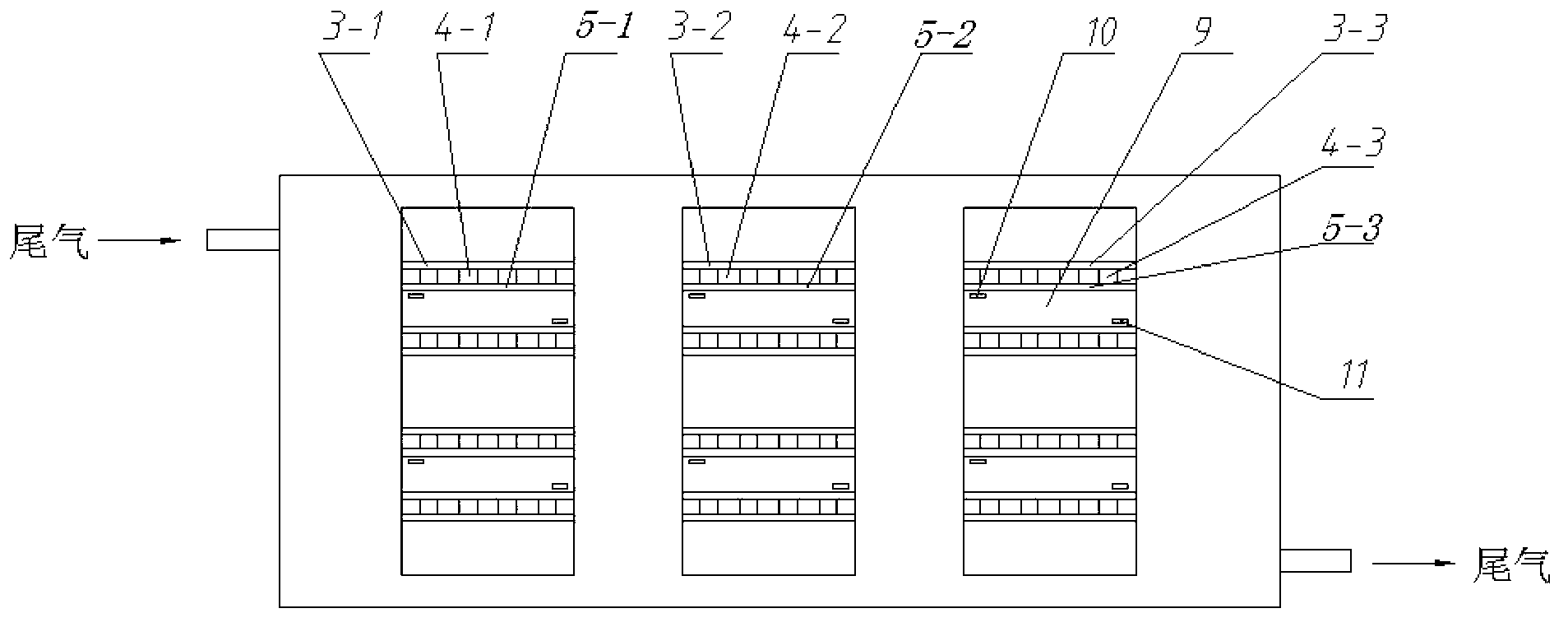

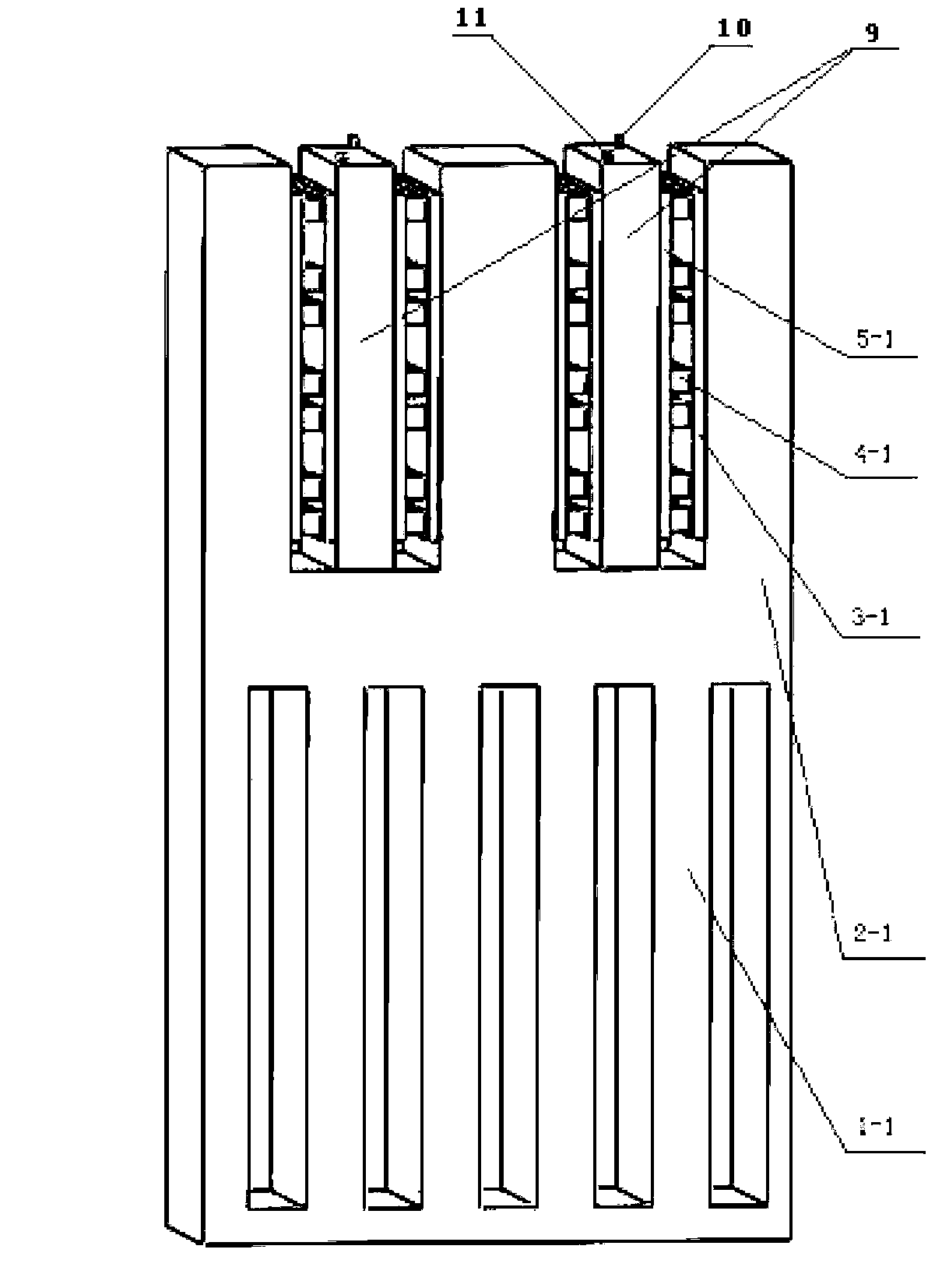

[0041] see Figure 4 , Figure 5 , the high-temperature automobile exhaust flows in along the inlet 7 of the exhaust passage 6, and the high-temperature phase-change heat transfer structure and the low-temperature phase-change heat transfer structure are placed in the exhaust passage 6 in order from high to low, and the exhaust gas first flows from the evaporation section 1 of the high-temperature phase-change heat transfer structure -1 to flow through the gap (see image 3 ), the shell material is made of stainless steel plate; the high-temperature working fluid is liquid metal sodium, which absorbs the heat of the exhaust gas and evaporates in the high-temperature evaporation section 1-1, and releases heat to the contacting parts when the steam flows upward into the high-temperature condensation section 2-1 The hot end 3-1 of the high-temperature thermoelectric material condenses into a liquid at the same time, and the condensed liquid flows back to the high-temperature eva...

Embodiment 2

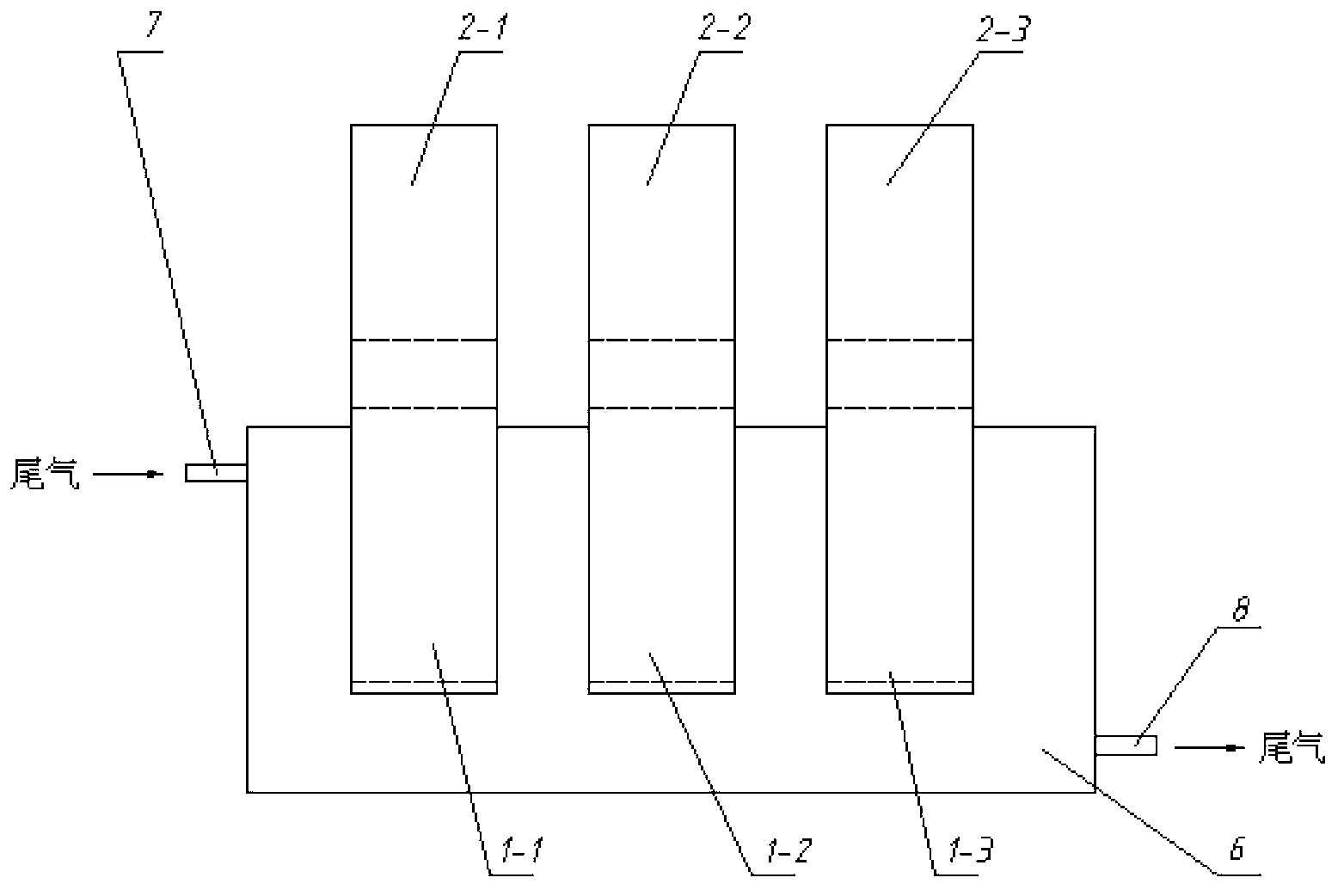

[0044] see figure 1 , figure 2 , the high-temperature automobile exhaust flows in along the inlet of the exhaust channel, and the high-temperature phase change heat transfer structure, the medium-temperature phase-change heat transfer structure and the low-temperature phase-change heat transfer structure are placed in the exhaust gas channel in order from high to low; flows through the gap in evaporation section 1-1 (see image 3 ), the shell material is made of stainless steel plate; the high-temperature working medium liquid is liquid metal potassium, which absorbs the heat of the exhaust gas and evaporates in the high-temperature evaporation section 1-1, and releases heat to the parts in contact with it when the steam flows upward into the high-temperature condensation section 2-1 The hot end 3-1 of the high-temperature thermoelectric material condenses into a liquid at the same time, and the condensed liquid flows back to the high-temperature evaporation section 1-1 from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com