Seed gas bubble micro heat exchanger and seed gas bubble micro heat exchanger system

A technology of micro heat exchangers and heat exchangers, applied in the direction of electrical components, electrical solid devices, semiconductor devices, etc., to achieve complex flow and heat transfer simplification, eliminate randomness, and solve the effects of high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

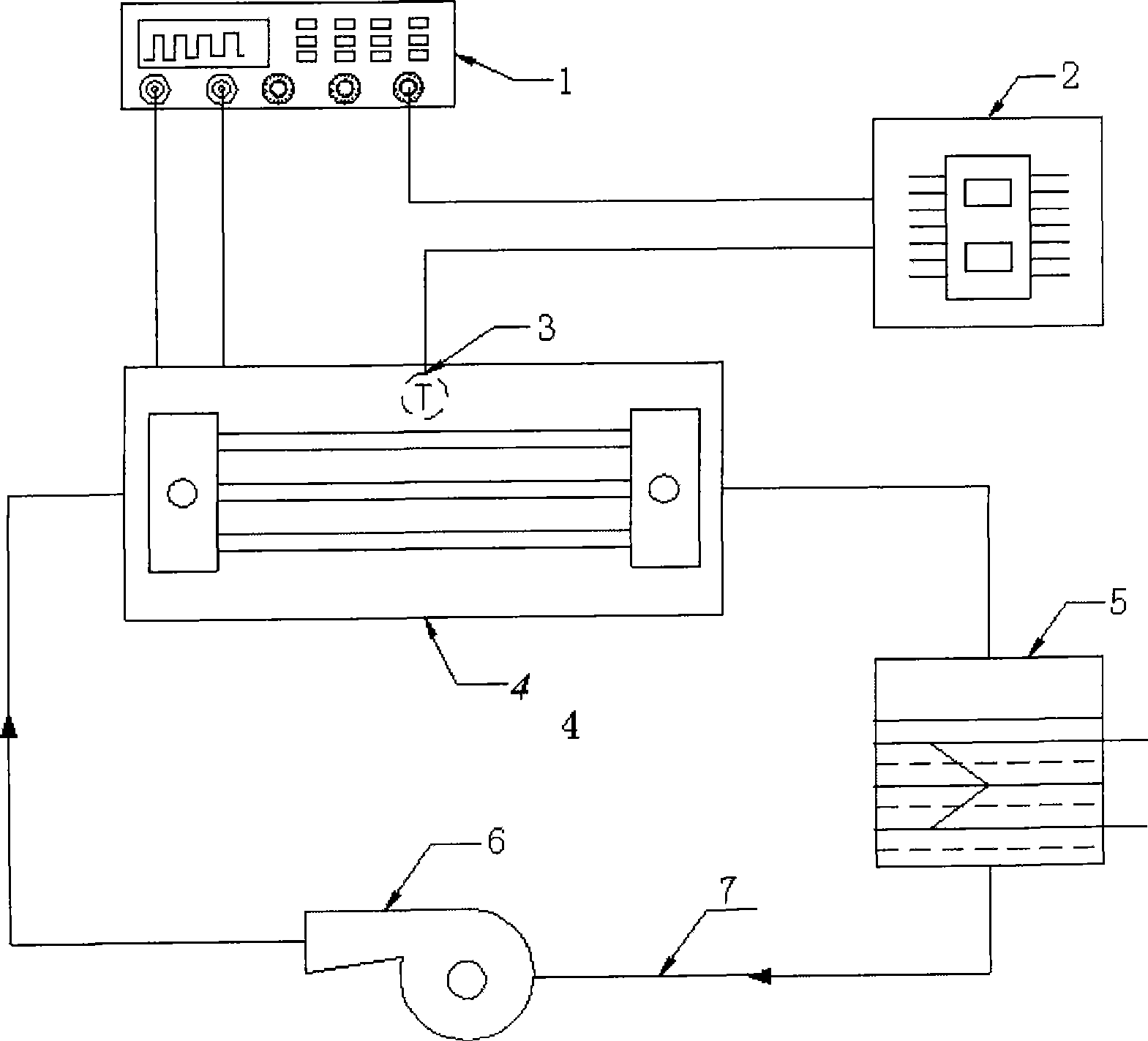

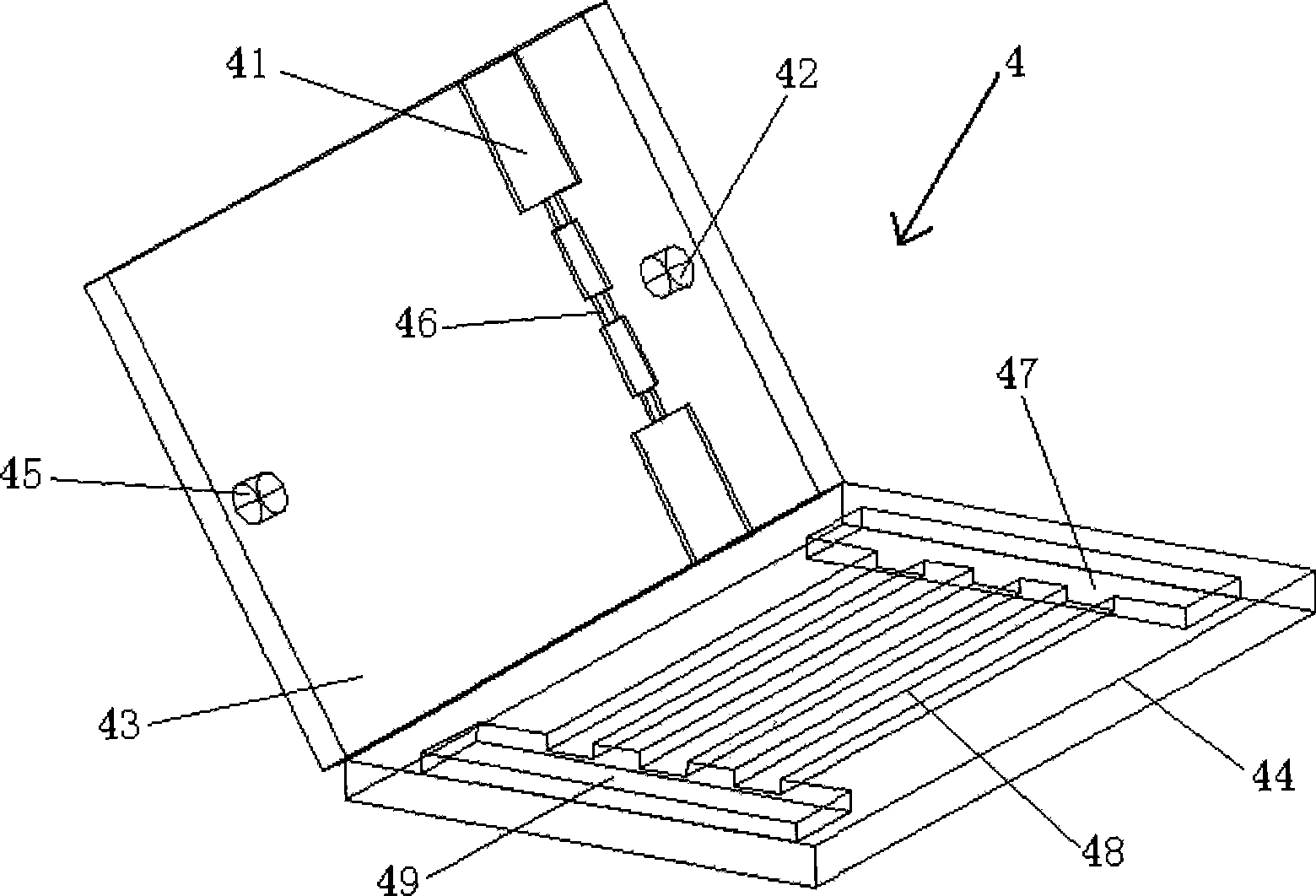

[0022] see figure 1 As shown, an external liquid supply circuit 7, a heat exchanger body 4, a final cold trap radiator 5, a pulse voltage generator 1, and a control circuit 2 are arranged around the heat exchanger body 4, and the pulse voltage generator 1 and the heat exchanger body 4 The electrical connection can provide an excitation voltage signal for the heat exchanger main body 4. A temperature sensor 3 is integrated on the heat exchanger main body 4. The control circuit 2 is electrically connected with the pulse voltage generator 1 and the temperature sensor 3 respectively, and the temperature sensor 3 detects The temperature on the main body 4 of the heat exchanger, and the temperature signal is transmitted to the control circuit 2, which is compared with the preset value by the control circuit 2, and the pulse voltage generator is controlled to adjust the pulse voltage frequency according to the operating temperature requirement to achieve control The purpose of heat t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com