Orthopedic surgery grinding experimental device with cooling and electrostatic atomization film formation functions

An experimental device, electrostatic atomization technology, applied in the field of medical devices, can solve the problems of wound treatment, complex surgical space, narrow and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] Below in conjunction with accompanying drawing, seven kinds of embodiments of the present invention are described in detail:

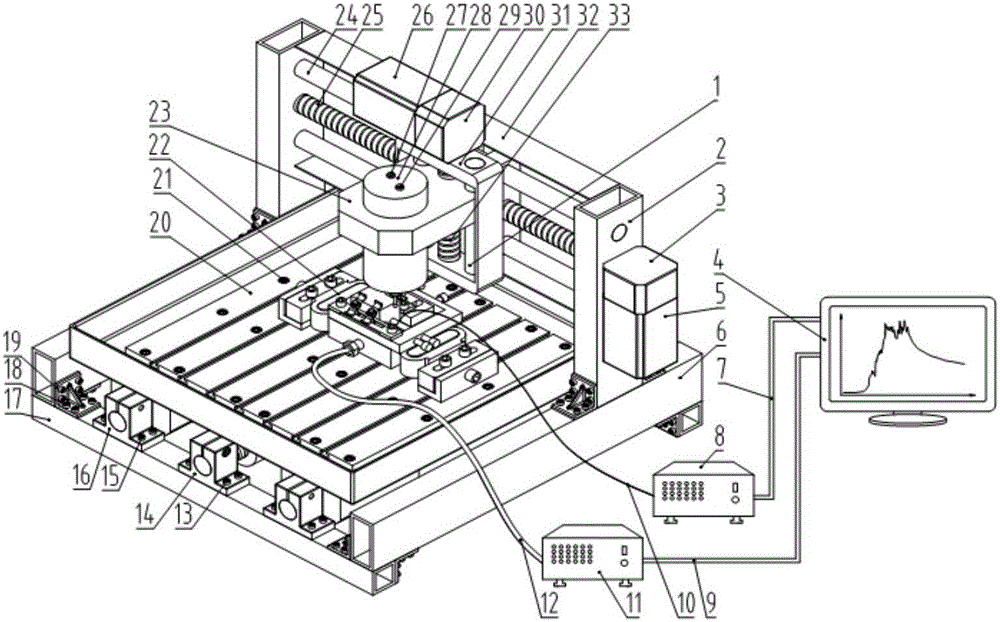

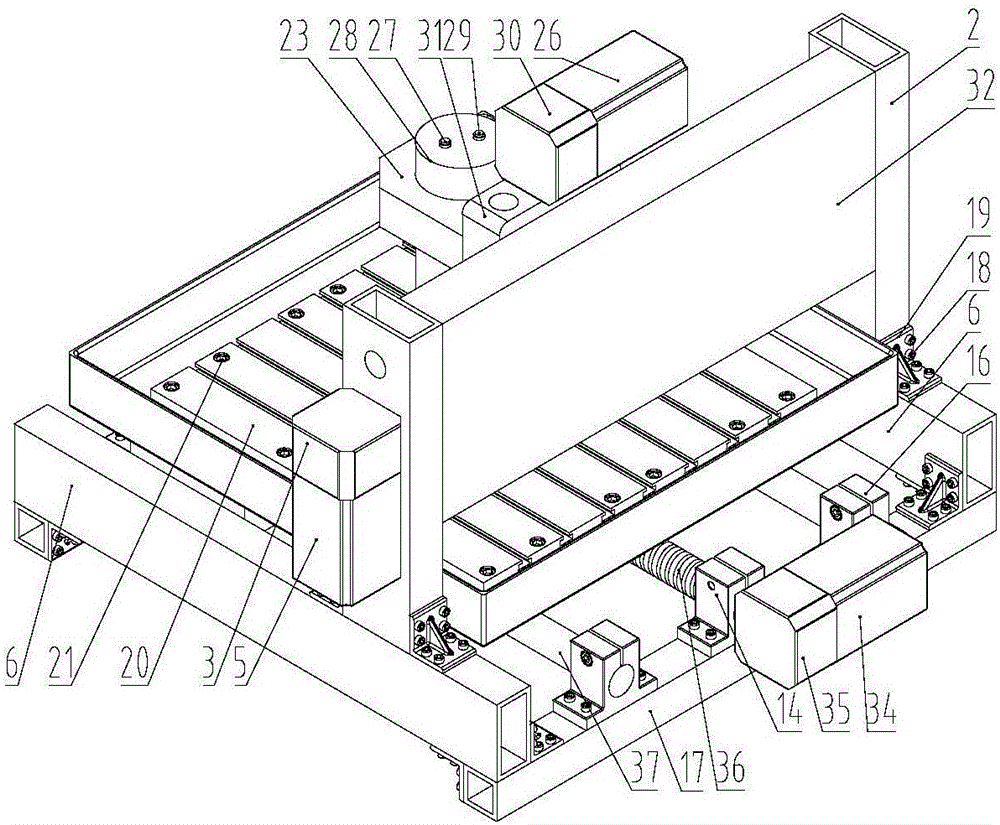

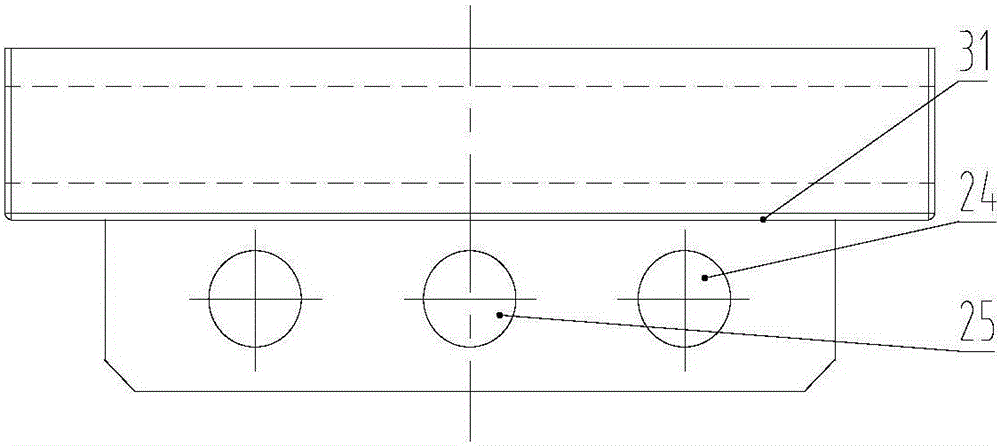

[0088] All embodiments of the present invention are in figure 1 The high-speed grinding surgery experimental platform shown is implemented. The experimental platform mainly consists of a linear three-axis platform (such as figure 2 shown), electric spindle 28, dynamometer I22, thermocouple 10 and control system 4. The linear three-axis stage includes X-axis structure, Y-axis structure and Z-axis structure. The X-axis structure is composed of an X-axis motor 5, an X-axis reducer 3, an X-axis screw 25, an X-axis guide rod 24 and an X-axis protection box 31. The X-axis screw 25 passes through the X-axis reducer 3 and the X-axis motor 5 Connection; there are 1 or 2 X-axis guide rods 24, and the X-axis guide rods 24 are arranged parallel to the X-axis lead screw 25. When the number of X-axis guide rods 24 is two, the two X-axis guide rods 24 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com