Semiconductor light source mining lamp

A technology of industrial and mining lamps and semiconductors, which is applied in the field of semiconductor light source industrial and mining lamps, and can solve problems such as the temperature rise of the radiator 13 and the temperature of the power supply box 14, and achieve the effect of reducing the temperature of the junction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

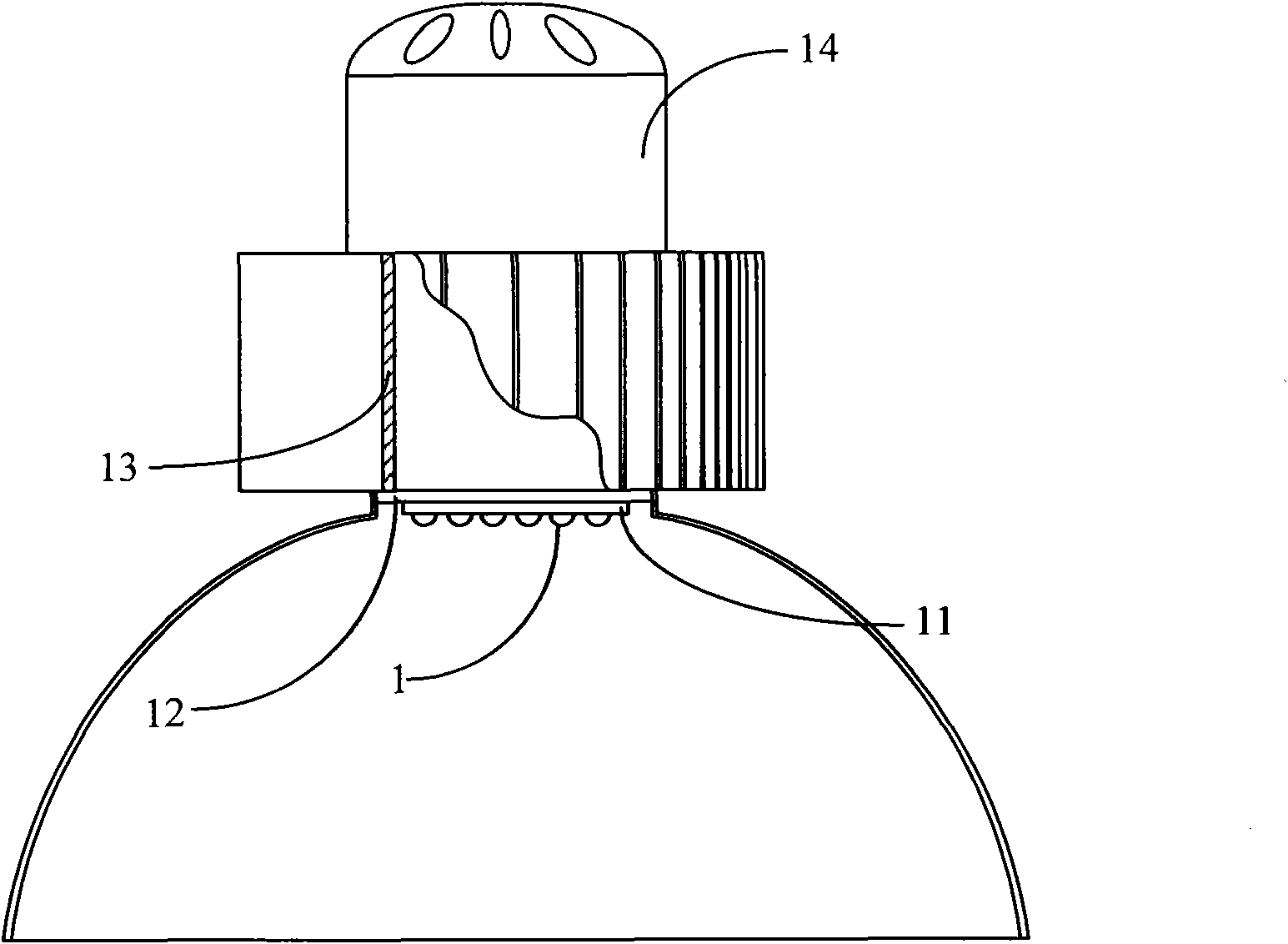

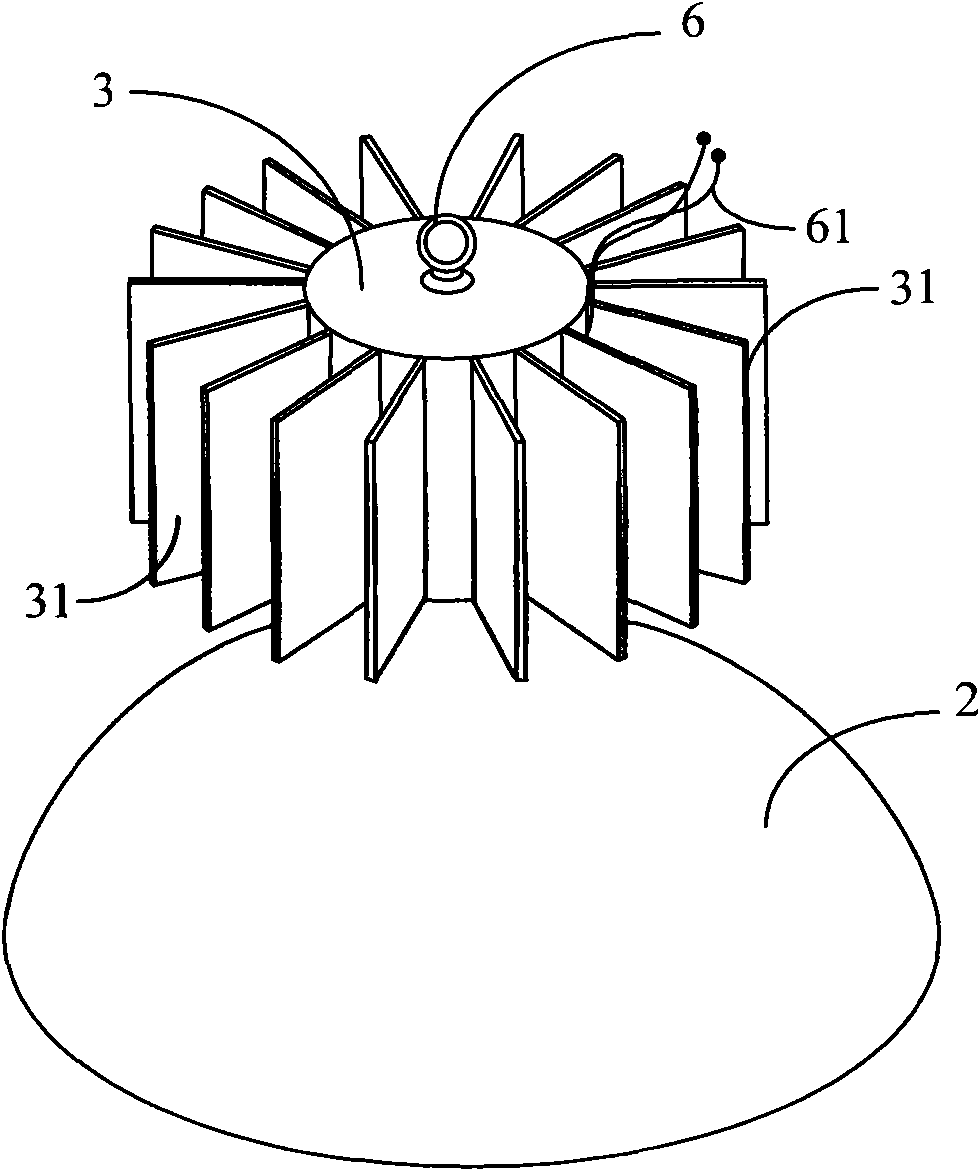

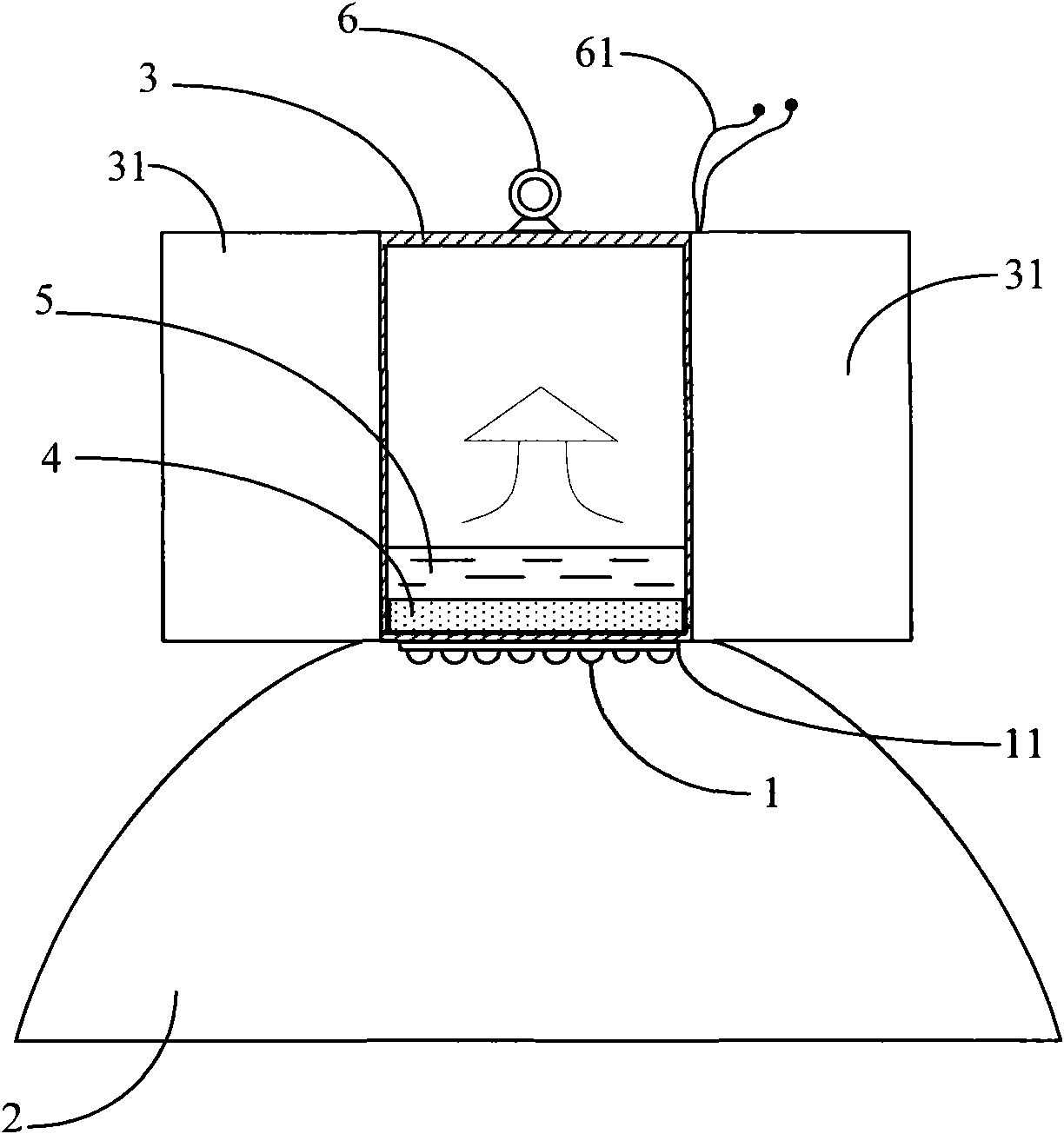

[0033] figure 2 It is a schematic structural diagram of a semiconductor light source industrial and mining lamp provided in Embodiment 1 of the present invention, image 3 for figure 2 The schematic diagram of the side sectional structure of the semiconductor light source industrial and mining lamp shown. The semiconductor light source industrial and mining lamp of this embodiment includes a heat sink and an aluminum substrate 11. One or more LED chips 1 are mounted on the surface of the aluminum substrate 11. Generally, a high-power industrial and mining lamp will include a plurality of LED chips 1, which are arranged in a distributed manner. on the aluminum substrate 11. In order to play a role in concentrating light, the lampshade 2 is generally connected to the aluminum substrate 11. The middle part of the lampshade 2 has a through hole and is arranged under the phase change heat transfer cylinder 3 to reflect the light emitted by the LED chip 1 when it is working.

...

Embodiment 2

[0043] Figure 4 The structure schematic diagram of the semiconductor light source industrial and mining lamp provided by the second embodiment of the present invention, this embodiment is a further improvement on the basis of the first embodiment. In order to clearly describe its structure, the lampshade is omitted in the figure.

[0044] The difference between this embodiment and the first embodiment is that: besides the driving circuit 61 , it also includes a driving power source 8 . The drive circuit 61 is connected to the drive power supply 8 and the LED chip 1; the heat dissipation area formed by the heat dissipation fins 31 is provided with a recessed portion 81 ( Figure 4 The region indicated by the dotted line in the middle), the driving power supply 8 is embedded in the recessed portion 81 opened on the heat dissipation fin 31 .

[0045] In this embodiment, the drive power supply 8 is arranged outside the phase-change heat transfer cylinder 3, the drive circuit 61...

Embodiment 3

[0050] Figure 5 The structural schematic diagram of the semiconductor light source industrial and mining lamp provided for the third embodiment of the present invention, as shown in Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the bulk device also includes: a built-in bin 9, which can also be designed as a cylinder, nested in the phase change heat transfer cylinder 3, and the built-in bin 9 9 is open at one end away from the aluminum substrate 11. The inner wall of the phase change heat transfer cylinder 3, the outer wall of the built-in chamber 9 and the annular top cover plate 34 together form a sealed cavity for filling liquid working fluid. The built-in compartment 9 is provided with a driving power supply 8 and a driving circuit 61 , and the driving circuit 61 is connected to the driving power supply 8 and the LED chip 1 .

[0051] The driving circuit 61 can be connected to the LED chip 1 by going around from the outside of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com