Plate type heat pipe with separation channels

A plate heat pipe and separation channel technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of complex processing, large friction resistance, etc., to expand the application range, improve heat transfer capacity, increase the volume of steam chamber and Effect of reservoir volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

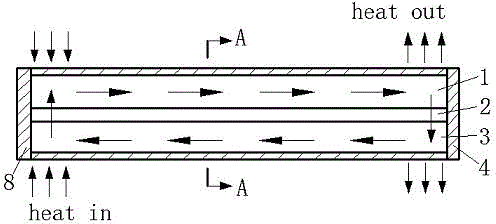

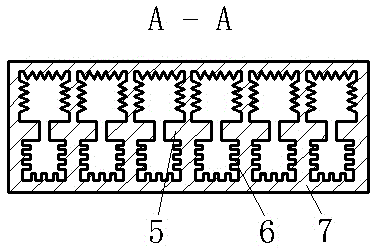

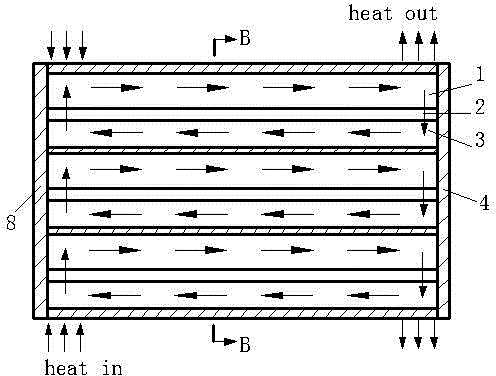

[0038] Such as figure 1 with figure 2 As shown, the long axis direction of the separation channel of the plate heat pipe is parallel to the horizontal plane, and the evaporation channel 1 is on the top, and the condensation channel 3 is on the bottom. Seam 2, the plate heat pipe base 7 is processed by integral molding, and the sealing ends 4 and 8 are sealed by vacuumizing and pouring working fluid. The direction of heat flow when the plate heat pipe works is as follows: figure 1 As shown, when the evaporating end is heated, the working fluid absorbs heat and vaporizes. Due to the effect of the gas pressure difference, the working medium gas rises to the upper evaporation channel 1, quickly transfers heat to the right to the condensing end, and the working fluid releases heat at the condensing end. After cooling into a liquid, under the action of the capillary pump force, it seeps through the capillary slit 2 to the condensation channel 3 located below, and under the capill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com