Graded heat exchange distributed control phase-change heat transfer system and heat transfer method

A technology of phase-change heat transfer and graded heat transfer, which is applied in the field of heat transfer enhancement, and can solve problems such as insufficient steam volume, affecting system economy and safety, and limited

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

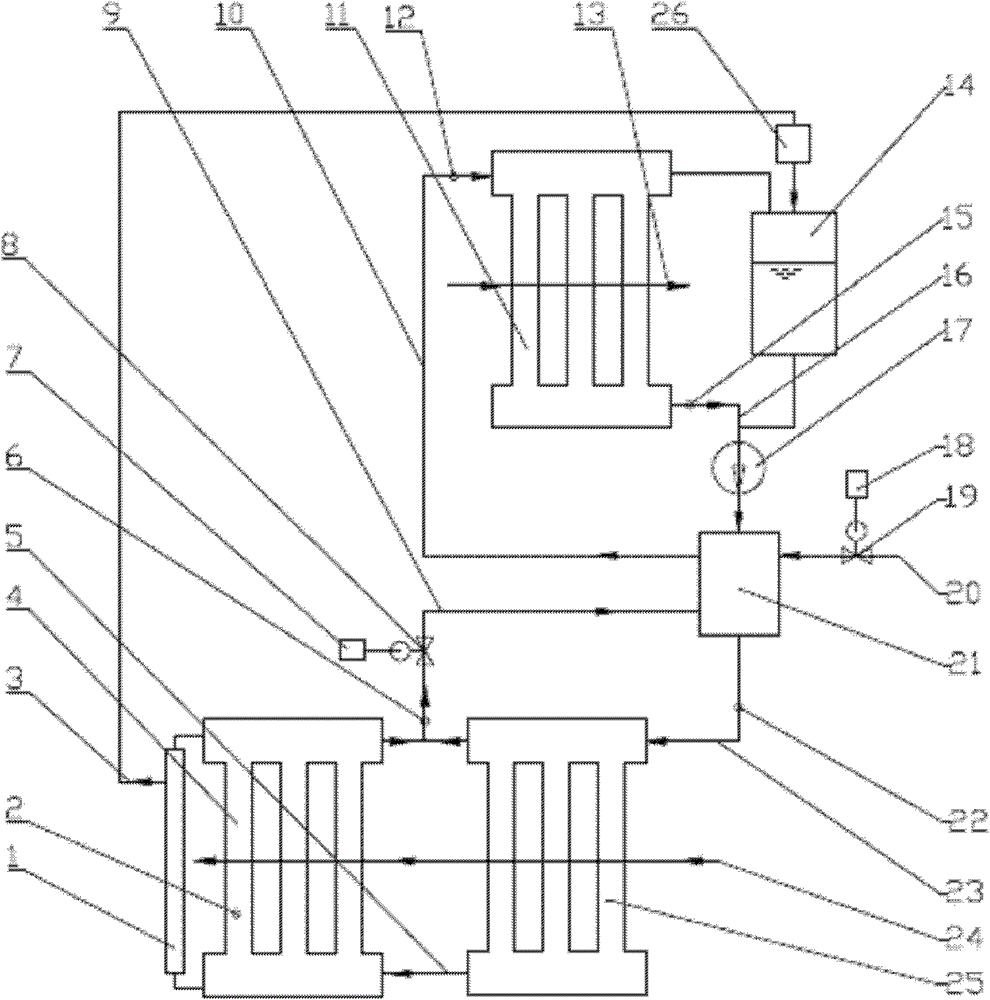

[0056] According to the split-controlled phase-change heat system of staged heat exchange in the present invention, the system includes a vapor-liquid heat exchanger 21, a low-temperature heat source heat exchanger 4, a high-temperature heat source heat exchanger 25, and a cold source heat exchanger 11, The system also includes a steam flow regulating valve 8, an external steam flow regulating valve 19, and a liquid storage container 1;

[0057] The upper header of the low-temperature heat source heat exchanger 4 is connected to the upper header of the high-temperature heat source heat exchanger 25 through the steam side communication pipe, and the lower header of the low-temperature heat source heat exchanger 4 is connected with the high-temperature heat source heat exchanger 25. The lower header of the lower header is connected through the liquid side connecting pipe 5; it is also possible to connect the upper header of the low-temperature heat source heat exchanger 4 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com