Heat management method for proton exchange membrane fuel cell based on array heat pipe phase change heat transfer

A proton exchange membrane, fuel cell technology, applied in fuel cells, fuel cell additives, circuits, etc., can solve the hidden danger of unsafe battery operation, reduce the energy conversion efficiency of battery packs, etc., achieve optimal design, ensure stability, The effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

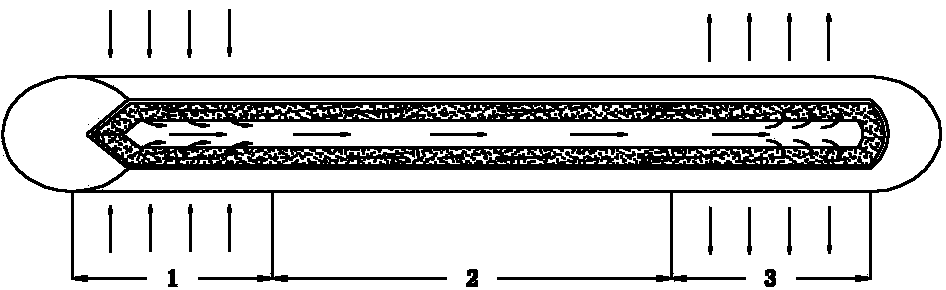

Embodiment 1

[0042] The size of the cross-section of the selected heat pipe is on two parallel copper panels of 82mm×30mm×0.3mm. 10 rectangular copper strips parallel to each other are welded by laser welding, and the rectangular copper strips are welded every 1.7 Inlaid between two copper plates at equal distances of mm, and the four circles of copper plates are sealed. Therefore, the adjacent copper bars and the upper and lower copper plates form a rectangular flow channel with an area of 1.50mm×0.80mm. The thickness of the upper and lower heat pipe cover plates is 0.3mm. The thin cover plate can well reduce the thermal resistance of the heat pipe itself. Heat production. In order to ensure the welding quality of the heat pipe, high-precision laser welding is adopted. The length of the heat pipe evaporation section is 30mm, the insulation section is 20mm and the condensation section is 30mm.

[0043] The pipe diameters are different, but the number of pipes is the same;

[0044] ...

Embodiment 2

[0048] like Figure 5-8 As shown, the number of tubes is different, the number of heat tubes is different when the tube diameter is the same and 0.3cm is used, and the heat dissipation is very different. In this experiment, 3, 5, 7 and 9 heat pipes were used in turn for comparative analysis.

[0049]

[0050] The results are clear, with temperatures dropping from an average of 55.15 degrees to 46.96 degrees. Therefore, it has been proved that the number of heat pipes has a great influence on the heat dissipation effect, so the array heat pipes should be used as much as possible to dissipate heat when cooling the fuel cell.

Embodiment 3

[0052]

[0053] from Figure 9-11 It can be seen that there is almost no change in temperature. It can be proved that the angle has no obvious influence on the heat dissipation effect, so in the heat pipe heat dissipation design of the fuel cell, in order to save space, an angled heat pipe can be used for design. When a large number of heat pipes are used, the temperature of the fuel cell has an obvious downward trend, which proves that the heat pipe can effectively and evenly release the waste heat generated by the fuel cell during operation, and reduce the temperature to keep it running at a good temperature. And the number of heat pipes has a great influence on the heat dissipation effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com