Motor with rotor cooled

A rotor and motor shaft technology, applied in the field of motor rotor cooling, can solve the problems of increased rotor temperature, decreased bearing service life, and high temperature at the bearing, so as to reduce weight and bearing burden, reduce temperature rise, and increase heat dissipation area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

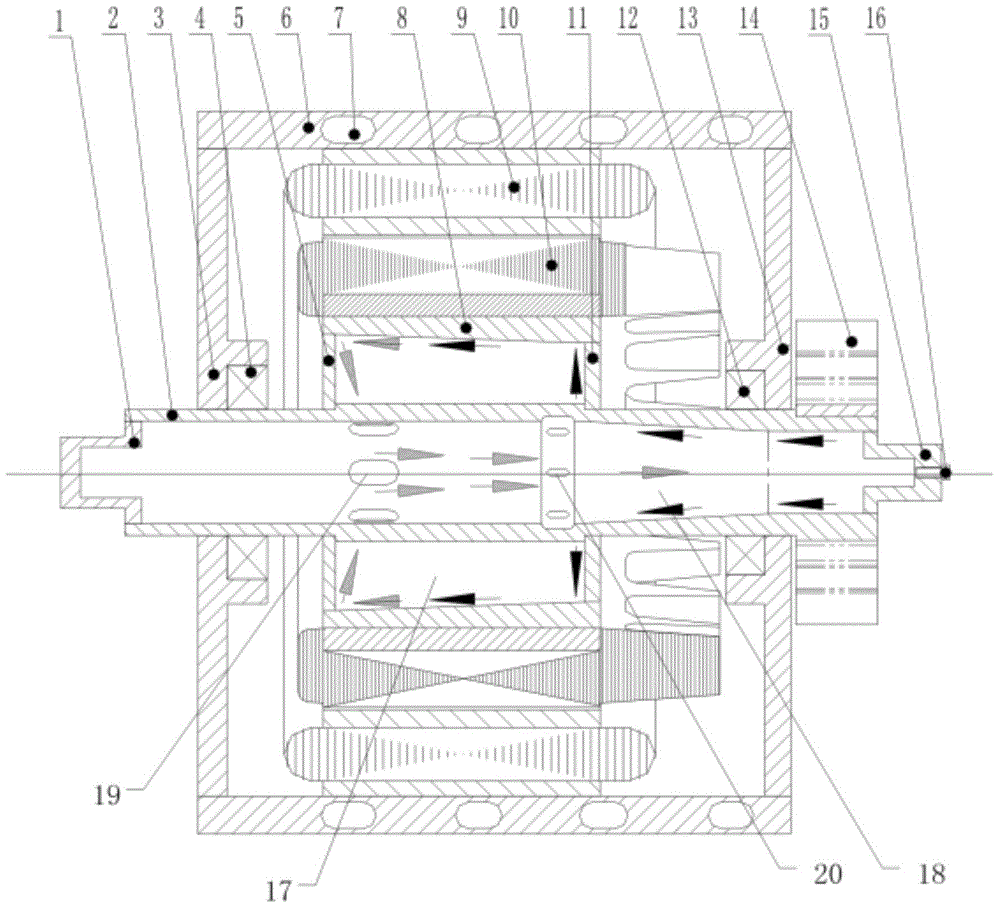

[0018] The technical scheme of the present invention will be further elaborated below in conjunction with the accompanying drawings. Such as figure 1 As shown, the rotor heat dissipation motor is composed of a stator assembly 9, a rotor assembly 10, a casing 6, a front end cover 3, and a rear end cover 13. The rotor assembly 10 can rotate relative to the stator assembly 9; The front bearing 4 and the rear bearing 12 at the center of the cover 3 , the rear end cover 13 are fixedly arranged with the rotor assembly 10 . A bracket is provided between the motor shaft 2 and the rotor assembly 10 to support the rotor. The motor may be a DC permanent magnet, AC asynchronous or switched reluctance motor, and if it is a permanent magnet motor, the above-mentioned rotor assembly is a permanent magnet fixed on a bracket. Wherein, a large amount of heat generated by the stator assembly 9 when the motor is in operation is discharged through the cooling channel 7 arranged on the casing.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com