Method and device for measuring solubility of refrigerant and refrigerating machine oil

A technique for refrigerating machine oil and measuring methods, which is applied in the direction of analyzing materials and instruments, and can solve problems such as reducing heat transfer efficiency, affecting the normal operation of compressors, and changing the viscosity of lubricating oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

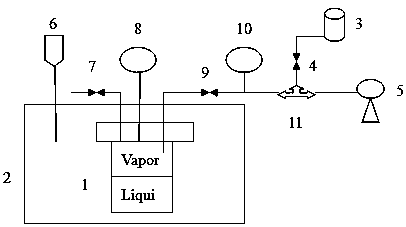

[0019] The determination of gas solubility under high pressure in this experiment mainly includes the following steps.

[0020] Experiment preparation: ①Device cleaning: Before testing, the inner wall of the autoclave, pipes and valves should be cleaned and dried with solvent to remove the remaining processing oil / liquid and water vapor in the autoclave;]②The volume measurement of the balance autoclave system: despite the high The kettle is marked with the nominal volume when it leaves the factory, but during the test, the volume occupied by the system connecting pipes and pressure gauges is unknown and needs to be actually measured. The volume of the balance kettle system is measured by the drainage method. The density of water is calculated by the Refprop 8.0 program according to the temperature and atmospheric pressure in the laboratory, and the volume change of each container caused by the change of temperature and pressure is ignored in the test; ③ System leak detection: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com